Valve system

A reversing valve and pilot technology, applied in the field of valve system, can solve the problems of limitation and high cost of equipment technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

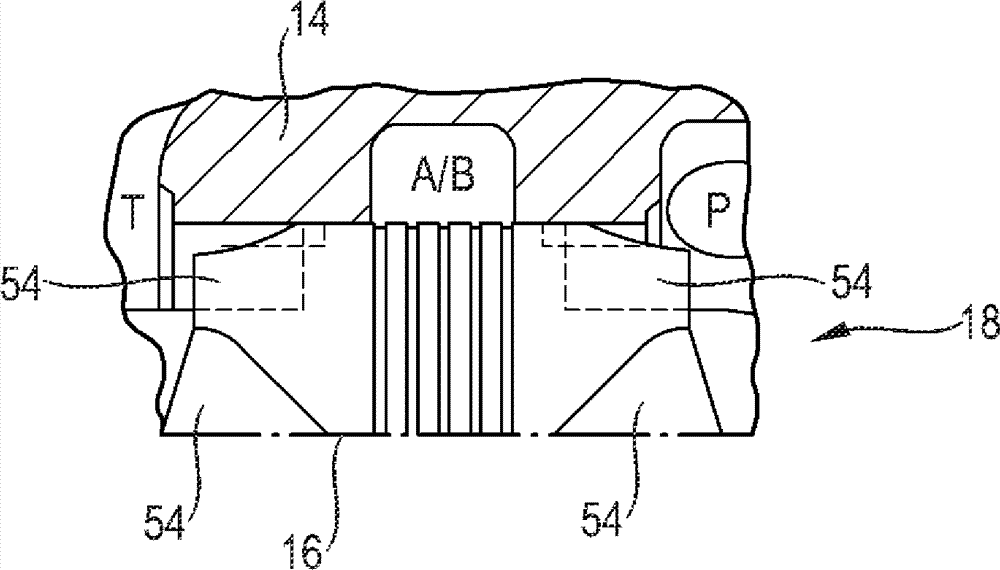

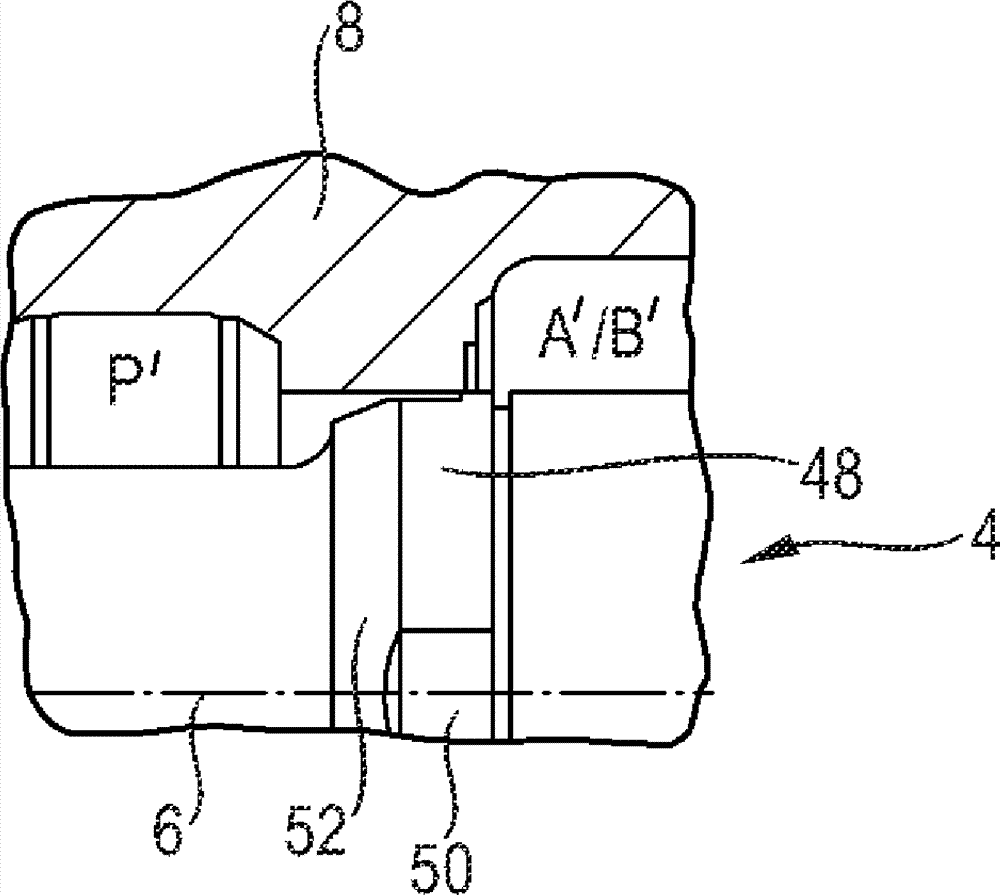

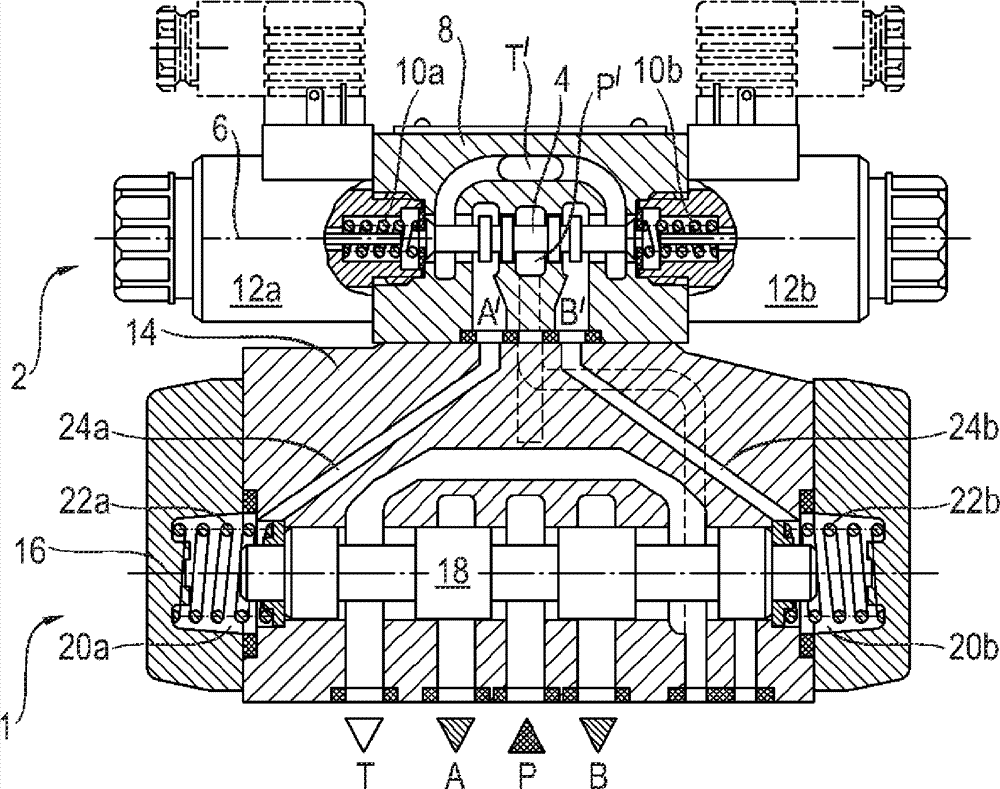

[0079] figure 1 A cross-sectional view of an embodiment of a pilot-controlled ballistic directional valve of a valve system according to the invention is shown. The directional control valve has a main stage 1 and a pilot control stage or pilot stage 2 . The pilot stage 2 has a pilot control piston or pilot piston 4, which in the figure 1 is shown in its basic position. The pilot piston 4 is displaceable in two directions along the longitudinal axis 6 . For this purpose, the pilot piston 4 is prestressed in its basic position in the housing or pilot housing 8 of the pilot control stage by means of two return springs 10a, 10b acting along the longitudinal axis 6 and can be moved by two pilot magnets 12a. , 12b are moved such that the pump connection P' is connected either to the first control channel A' or to the second control channel B'. The respective further control channel A' or B' is discharged towards the tank connection here.

[0080] The pilot stage 2 is fastened ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com