Modularly-parallel, multi-machine and energy-saving reliability testing device for hydraulic pumps and hydraulic motors

A technology of hydraulic motor and test device, which is applied in the direction of fluid pressure actuation device, fluid pressure actuation system test, mechanical equipment, etc., can solve the problems of inconvenient installation, numerous hydraulic components, complicated system structure, etc. stability and accuracy, ease of installation and flexibility, the effect of simplifying the system structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

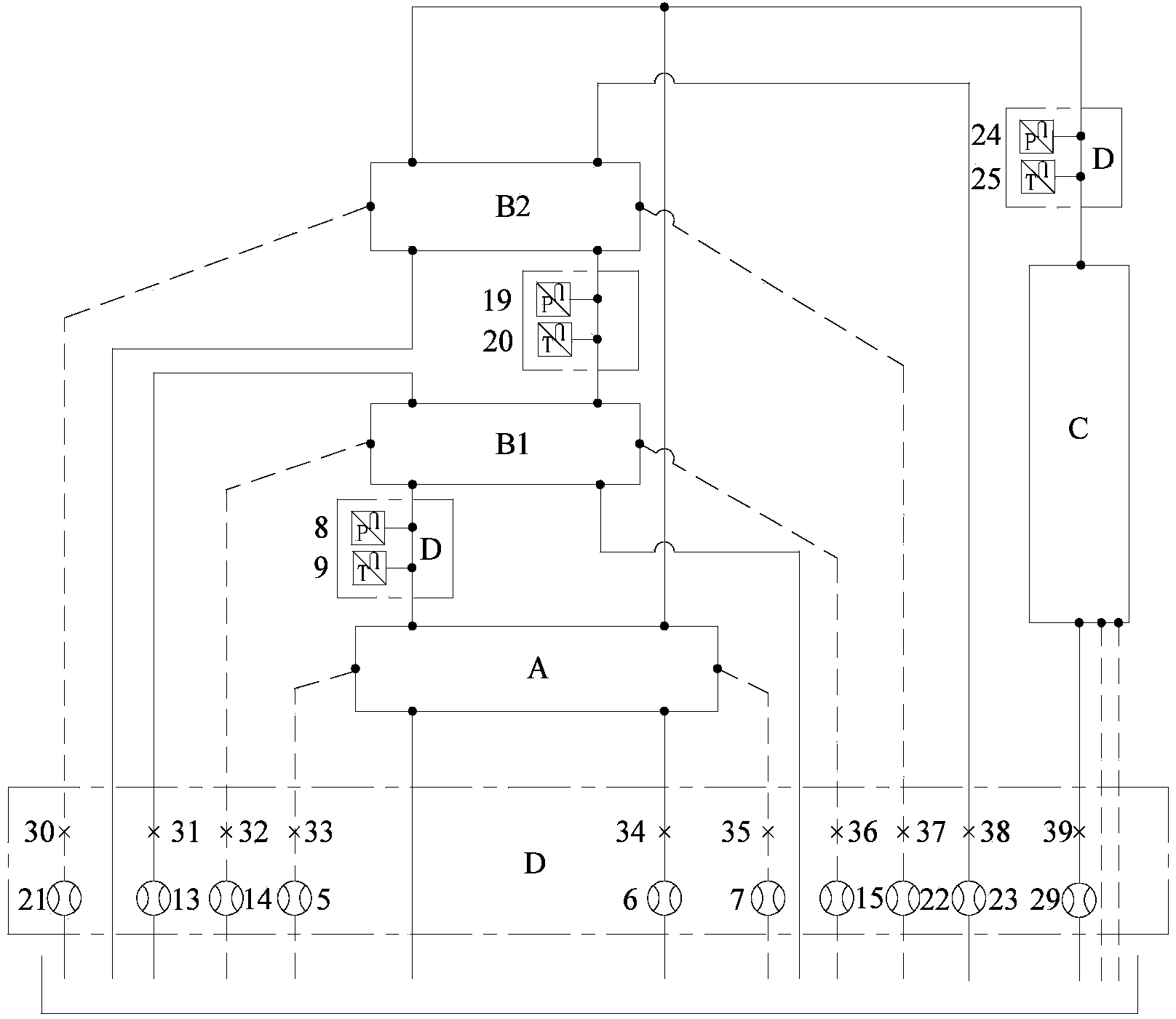

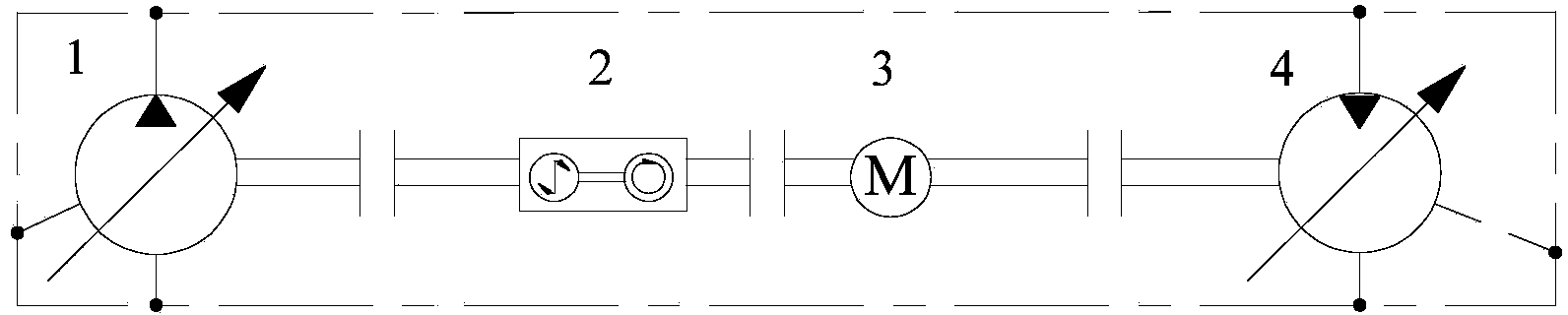

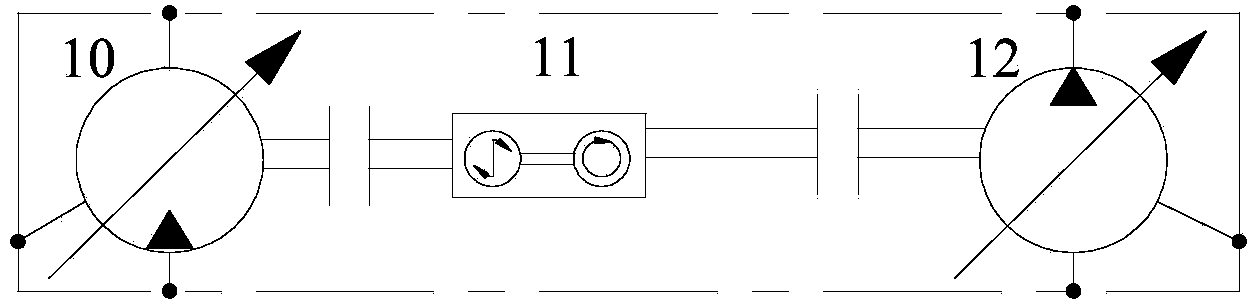

[0015] exist Figure 1~5 Among them, No. 1 tested hydraulic pump 1, No. 1 torque tachometer 2, motor 3, and No. 6 tested hydraulic motor 4 are coaxially connected through couplings to form power and power recovery system module A; No. 1 flowmeter 5, No. 2 flowmeter 6 and No. 3 flowmeter 7 respectively measure the leakage flow rate of No. 1 tested hydraulic pump 1 and the oil return flow rate and leakage flow rate of No. 6 tested hydraulic motor 4 . When the test device is started, the motor 3 drives the No. 1 tested hydraulic pump 1 to rotate, and the No. 1 tested hydraulic pump 1 drives the No. 2 tested hydraulic motor 10 to rotate. The pipeline between the two is connected with the No. 1 pressure sensor 8, 1 No. temperature sensor 9 is used to test the working pressure and oil temperature between No. 1 tested hydraulic pump 1 and No. 2 tested hydraulic motor 10 respectively. No. 2 tested hydraulic motor 10, No. 2 torque tachometer 11, and No. 3 tested hydraulic pump 12 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com