A regenerative braking continuously variable transmission for vehicles

A continuously variable transmission, regenerative braking technology, applied in transmission, fluid transmission, belt/chain/gear, etc., can solve the problems of large volume, reduced engine installed power, complex structure, etc. The effect of small installed power and improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

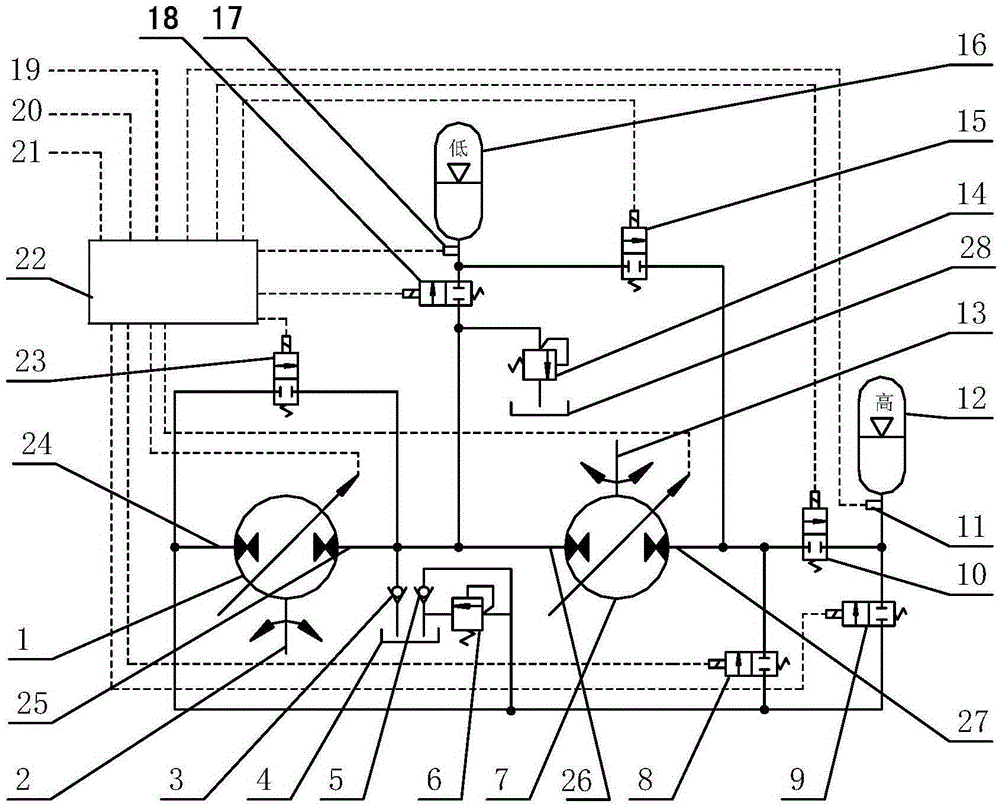

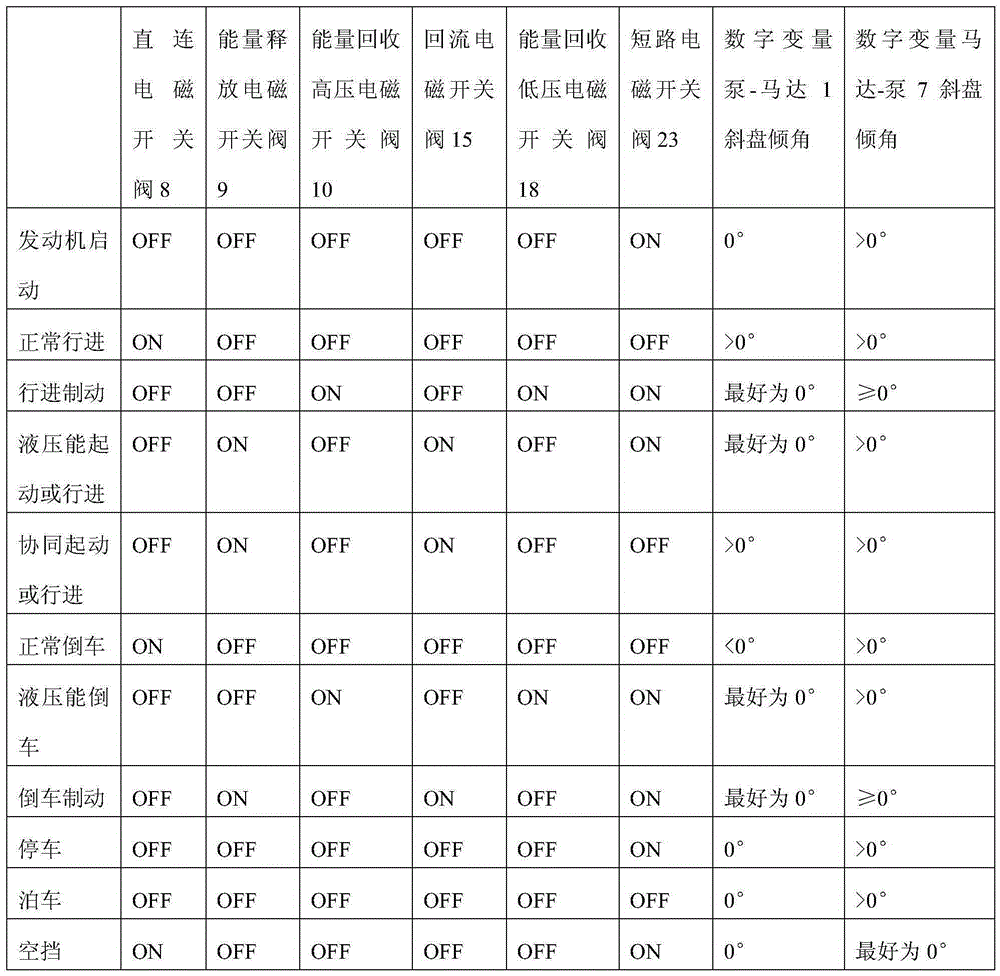

[0011]The main structure of this embodiment includes a digital variable pump-motor 1, an input shaft 2, a reverse fuel supply check valve 3, a first fuel supply tank 4, a vehicle feed fuel check valve 5, a reverse safety valve 6, a digital variable motor- Pump 7, direct connection electromagnetic switch valve 8, energy release electromagnetic switch valve 9, energy recovery high pressure electromagnetic switch valve 10, high pressure sensor 11, high pressure accumulator 12, output shaft 13, car entry safety valve 14, return flow electromagnetic switch valve 15 , low-pressure accumulator 16, low-pressure sensor 17, energy recovery low-voltage electromagnetic switch valve 18, brake pedal signal line 19, accelerator pedal signal line 20, gear position signal line 21, electronic control unit 22, short-circuit electromagnetic switch valve 23, the first An inlet 24, a first outlet 25, a second inlet 26, a second outlet 27 and a second fuel tank 28; one end of the input shaft 2 is dir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com