Sealing device with easy loading and unloading cover and sealing method thereof

A sealing device and convenient technology, applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve the problems of inappropriate operation method, troublesome disassembly and installation, large number of connecting bolts, etc. Reliable effect of dismantling and box connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

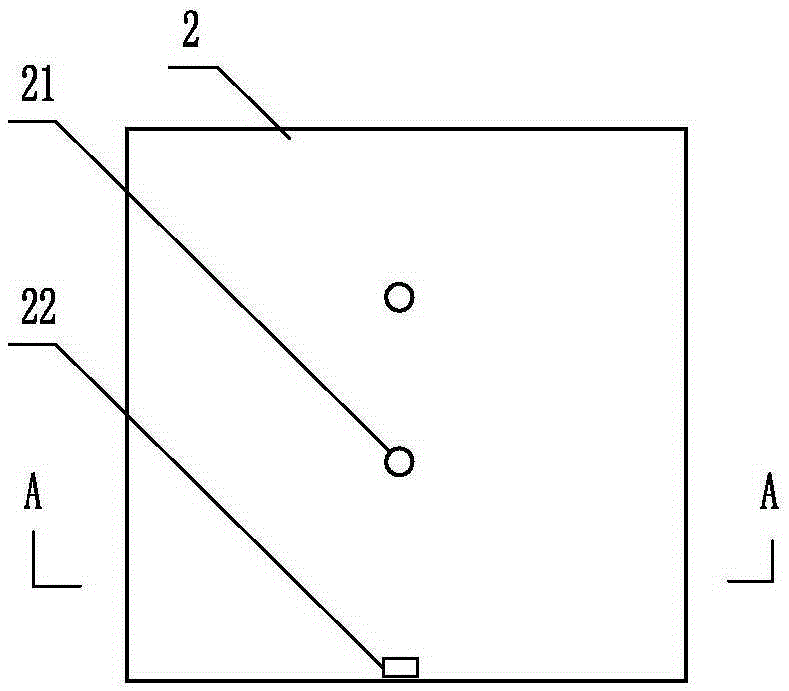

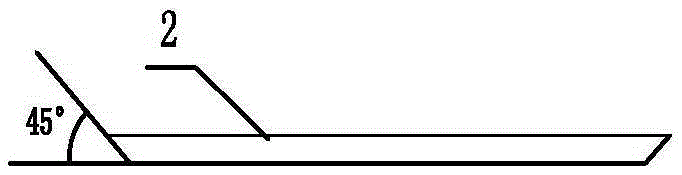

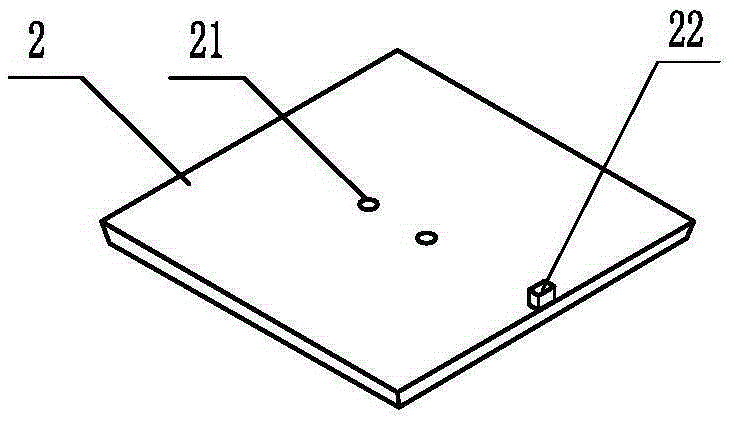

[0041] A sealing device with a convenient loading and unloading cover, comprising a three-dimensional box body 1 with a box opening and a box cover 2, including a three-dimensional box body 1 with a box opening and a box cover 2, and a box cover is connected to the inside of the box opening The rectangular frame 3 that provides support, the upper end surface of the rectangular frame is lower than the port of the box body, the box cover is a rectangular flat plate with a shape corresponding to the box mouth, and its four side end faces are 45° inclined planes, and the box cover is connected to the inside of the box body. There is a small gap, and there is a small hole 21 for vacuuming on the box cover, and a detachable vacuum suction cup 7 is connected to the small hole, and the vacuum suction cup has a threaded joint for connecting the air pipe ; The outer periphery of the box is provided with a rectangular iron hoop 5 for reinforcing the box and reducing the deformation of the...

Embodiment 2

[0045] The sealing method of the above-mentioned sealing device with a convenient loading and unloading cover comprises the following steps:

[0046] (1) Apply a continuous and uniform layer of thin glass glue on the 45-degree slope on the four sides of the box cover;

[0047] (2) Take a thin-walled plastic cloth that is not bonded to the glass glue, and apply a layer of wax oil on the plastic cloth;

[0048] (3) Before the glass glue starts to harden, cover and tighten the box cover coated with glass glue with the above-mentioned plastic cloth, so that there are no wrinkles and breaks on the edge of the bevel;

[0049] (4) Apply a continuous and uninterrupted layer of glass glue on the top surface of the rectangular frame of the box to form a 45° slope;

[0050] (5) Before the glass glue starts to harden, slowly join and press the box cover covered with plastic cloth with the 45° inclined glass glue on the top surface of the rectangular frame:

[0051] A. Grasp the pressin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com