A jet mixer

A technology of jet water mixer and water mixer, which is applied in jet pumps, machines/engines, lifting valves, etc., which can solve the problems of high user comfort, difficulty in guaranteeing water outlet effect, increased difficulty of use, etc., and achieves a simple operation mode Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

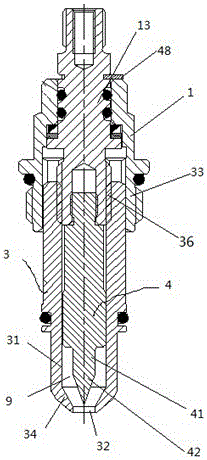

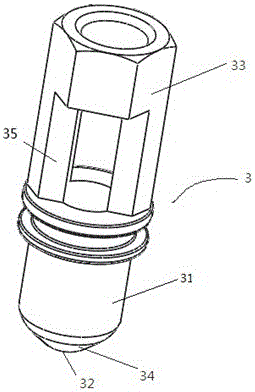

[0058] Such as Figure 10 As shown, this embodiment provides a jet water mixer, including a water mixer body A and a jet injection valve B, the water mixer body A has a cold water port A1, a hot water port A2 and a water mixing outlet, the jet The injection valve B has a cold water inlet B1 and a hot water inlet B2, the cold water inlet A1 communicates with the cold water inlet B1, and the hot water inlet A2 communicates with the hot water inlet B2, by adjusting the cold water inlet A1 and the The opening size of the hot water port A2 is used to adjust the amount of cold water and hot water entering the jet injection valve B.

[0059] In this embodiment, the opening size of the cold water port A1 is adjusted through the cold water adjustment switch, and the opening size of the hot water port A2 is adjusted through the hot water adjustment switch. In this embodiment, the cold water adjustment switch It has the same structure as the hot water regulating switch.

[0060] The co...

Embodiment 2

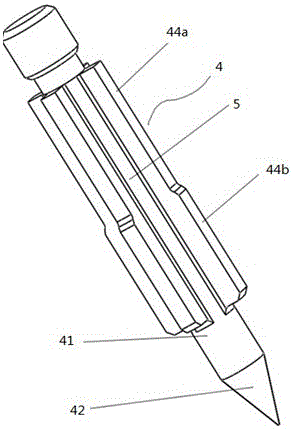

[0087] Such as Figure 7 As shown, this embodiment is an improvement on the basis of the jet mixer provided in embodiment 1, and the main improvement is that the supporting body of the spray needle 4 adopts a different structure. In this embodiment, the support body is an annular support plate 45 arranged on the needle body 41, and a plurality of flow guides for the fluid channel 5 are formed on the surface of the annular support plate 45. Hole 46. The inflow of cold water is unobstructed, and can evenly support the spray needle 4 .

Embodiment 3

[0089] Such as Figure 6 As shown, this embodiment is an improvement on the basis of the jet mixer provided in embodiment 1, and the main improvement is that the supporting body of the spray needle 4 adopts a different structure. In this embodiment, the supporting body is a circular ring 43, and the circular ring 43 is connected to the needle body 41 through a plurality of ribs 40, and the fluid channel 5 is formed between the ribs 40. This arrangement not only ensures smooth inflow of cold water, but also supports the spray needle 4 evenly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com