Negative-pressure draw-out type coal layer gas content spot sampling method

A coal seam gas and fixed-point sampling technology, which is applied to the sampling device and other directions, can solve the problems of long sampling time, small gas loss, and low gas desorption speed, and achieve the effect of shortening sampling time, small gas loss and improving sampling efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

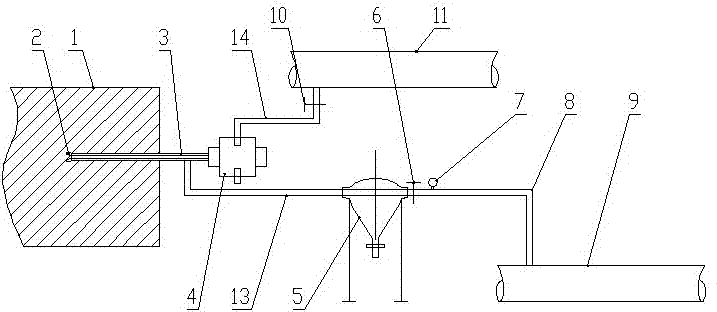

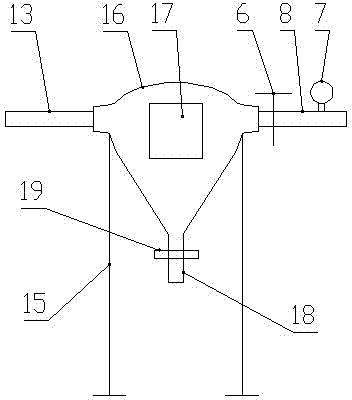

[0036] Embodiment one, such as figure 1 and figure 2 As shown, the negative pressure extraction type coal seam gas content fixed-point sampling method includes the following specific steps:

[0037] (1) Select a suitable test location for coal seam 1, arrange the drilling device for drilling operations, and arrange a negative pressure extraction sampling device next to the drilling device;

[0038] (2) During the drilling process, pressurized air is used to send the inside of the drill pipe 3 to the bottom of the hole, and the cuttings are blown out from the gap between the hole wall and the drill pipe 3;

[0039] (3) When the borehole is drilled to the predetermined sampling depth, stop drilling and blow off the remaining coal dust in the hole with compressed air;

[0040] (4), connecting the sampling pipe 13 of the negative pressure extraction type sampling device with the drill pipe 3 of the drilling device;

[0041] (5), then continue to drill, and open the negative pr...

Embodiment 2

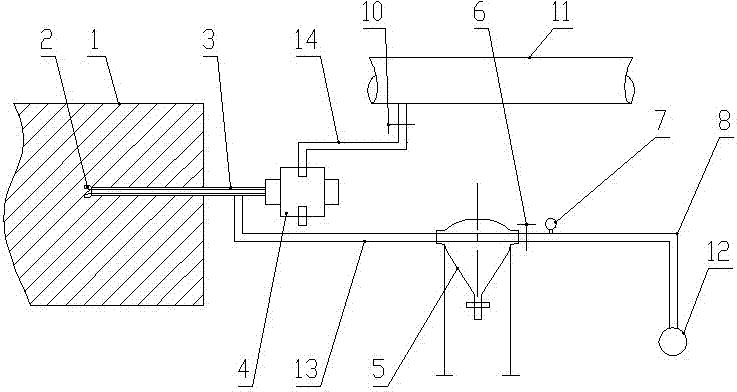

[0049] Embodiment two, such as image 3 As shown, the difference between this embodiment and the first embodiment is that: the outlet of the connecting pipe 8 is provided with a jet injector or a negative pressure pump 12 .

[0050] The negative pressure of the gas extraction pipeline 9 can be used in mines with gas extraction pipeline 9, and the mine without gas extraction pipeline 9 needs to use jet ejector or negative pressure pump 12 as a means of generating negative pressure to extract coal samples. power. The sampling process can be completed within tens of seconds, which greatly improves the sampling efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com