Single-beam NDIR (non-dispersive infrared) gas sensor and miner helmet provided with same

A non-dispersive infrared, single-beam technology, applied to helmets, instruments, helmet covers, etc., can solve the problems of large size, unreliable quality, and increased use costs of non-dispersive infrared gas sensors, so as to prevent methane explosions and/or or flood hazards, reducing the frequency of mine disasters, and reducing product size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

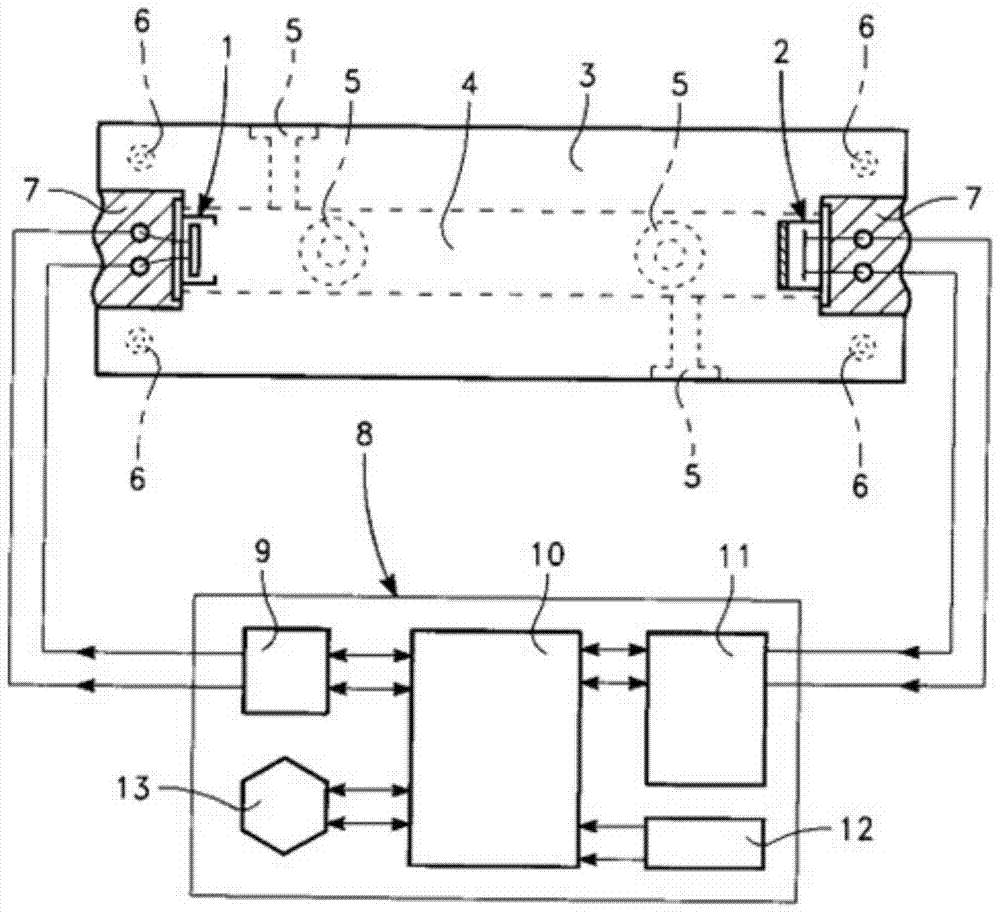

[0030]The accompanying drawings disclose, without limitation, the structural schematic diagrams of the preferred embodiments involved in the present invention; the technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

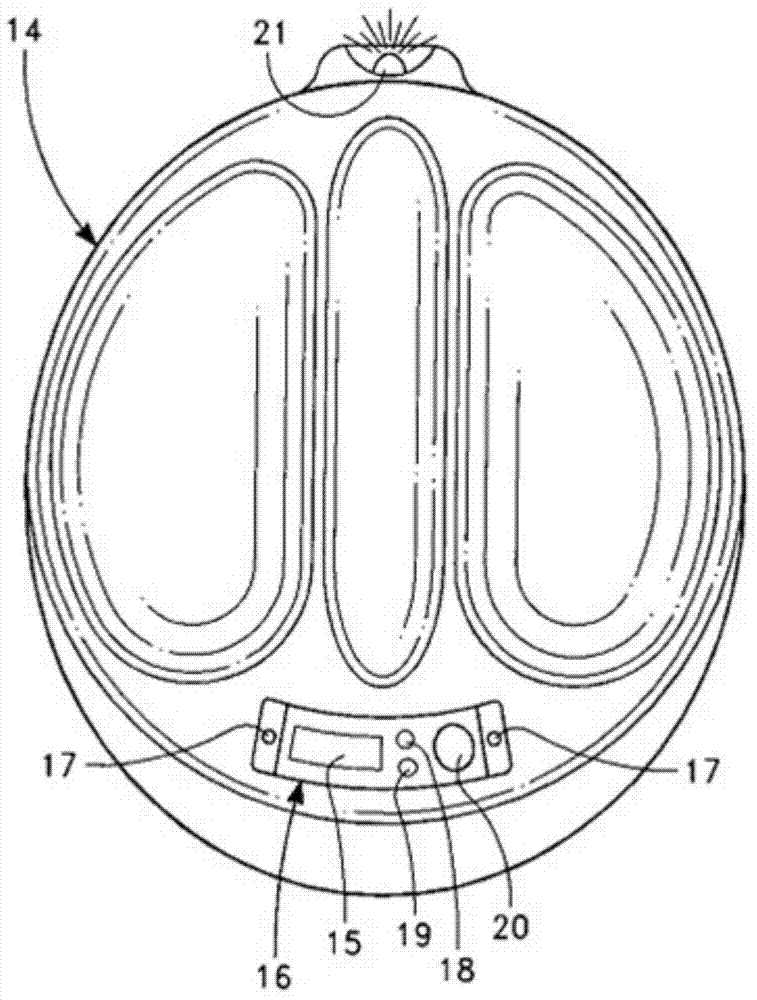

[0031] The main objective of the present invention is to make it widely applicable by eliminating or correcting the problems of output drift, large size and high cost of existing non-dispersive infrared gas sensors. In addition, the present invention locates its unique application in the gas sensor used by miners working underground, which can make miners notice the danger of methane explosion or underground flood, and avoid the frequent occurrence of mine accidents in the current coal mine operation process.

[0032] The single-beam non-dispersive infrared gas sensor of the present invention is used to detect the concentration of the gas to be detected, such as figure 1 As shown, it include...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com