Method for predicting fatigue life of BGA (Ball Grid Array) welding spot under heat-vibration combined loads

A fatigue life prediction, combined load technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problems of accelerated solder joint crack propagation, solder joint failure, and actual situation inconsistency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

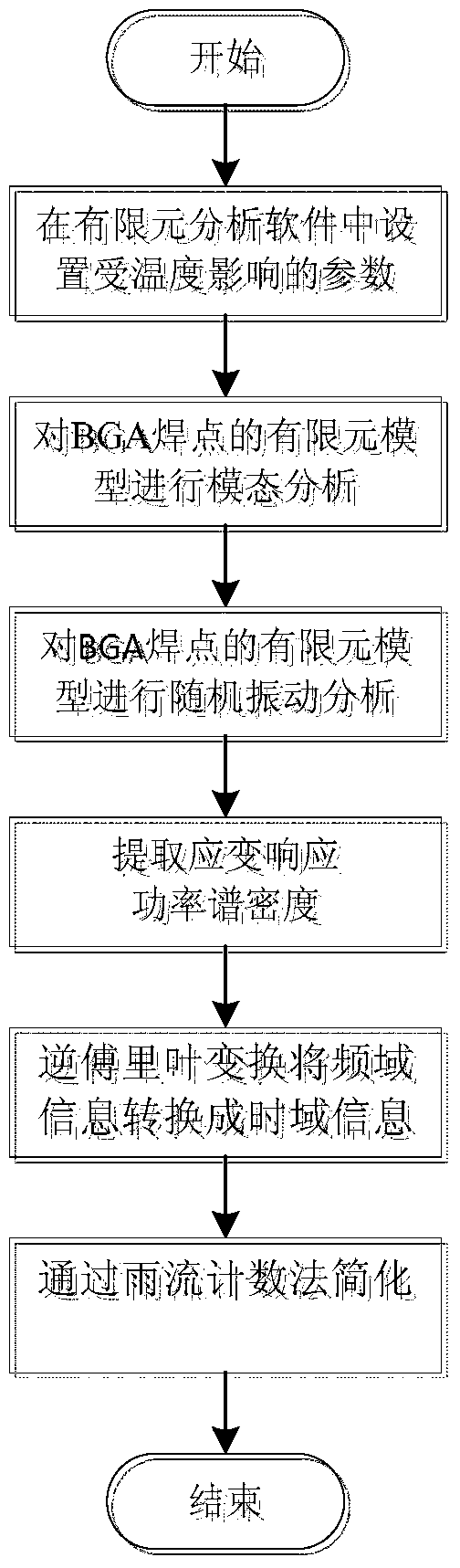

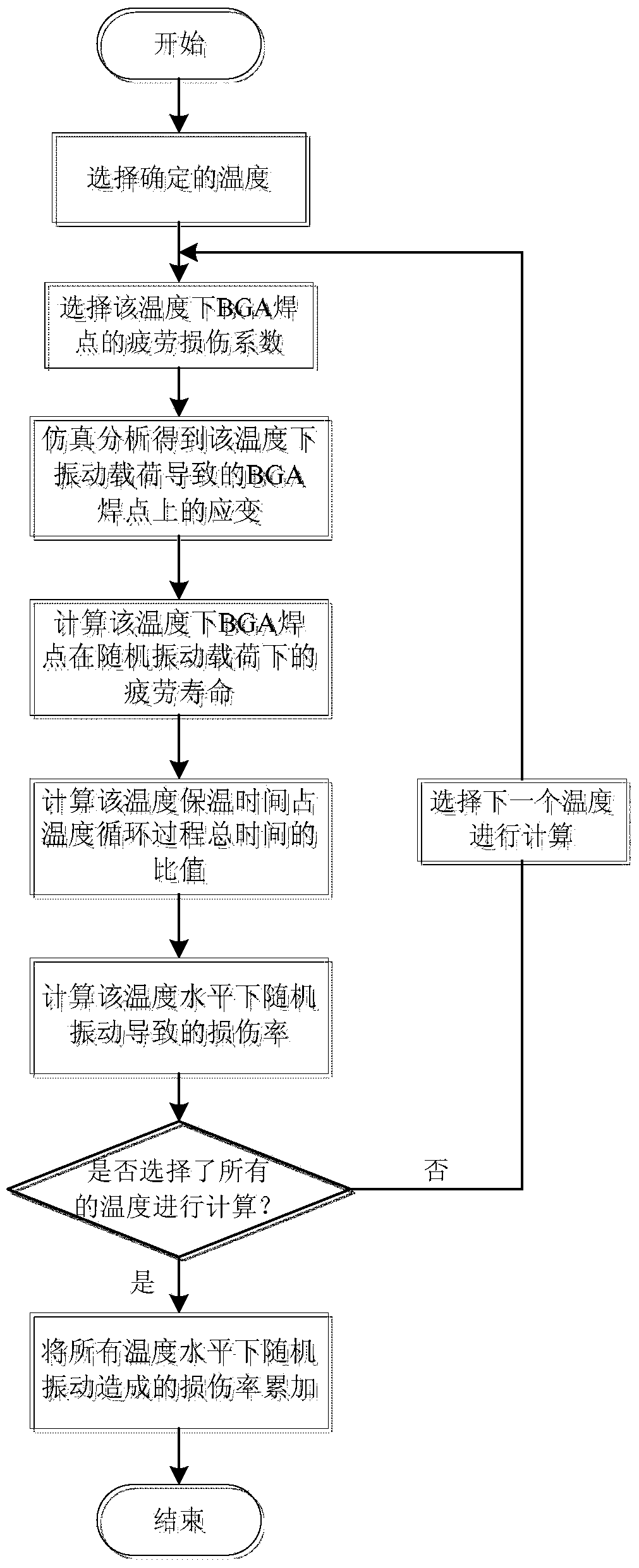

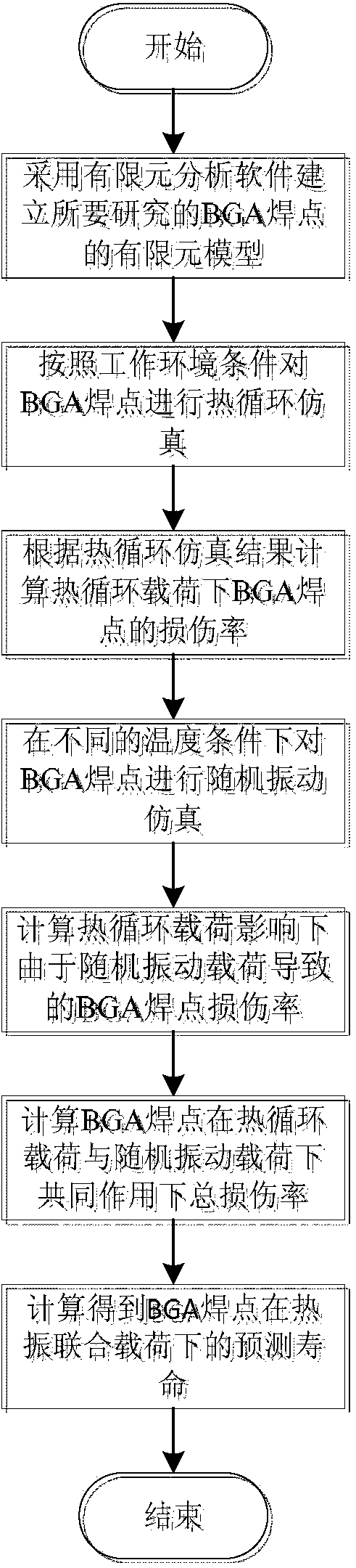

Method used

Image

Examples

Embodiment example

[0095] Taking the solder joints of BGA packaged components of model BGA225T1.5-DC15 as an example, the application of this method is introduced, and the usability and effectiveness of the method for predicting the fatigue life of BGA solder joints under thermal shock combined load are verified.

[0096] Step 1: Use Surface Evolver software to model a single BGA solder joint, input initial condition parameters, as shown in Table 1, and establish a finite element model of this BGA solder joint.

[0097] Table 1 Initial condition parameter table

[0098] parameter name

accurate value

Solder ball additional gravity load

0.009996g

480erg / cm2

Solder ball density

9g / cm3

Top Pad Diameter

0.56mm

Equivalent Solder Ball Diameter

0.76mm

[0099] Step 2-Step 3: Use Ansys software to perform thermal cycle simulation on the BGA solder joint finite element model, and the temperature range ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com