Positive active material

A positive electrode active material and material quality technology, applied in the direction of battery electrodes, cobalt compounds, non-aqueous electrolyte batteries, etc., can solve the problems of insufficient performance in actual use and achieve high-capacity effects

Active Publication Date: 2014-05-07

MURATA MFG CO LTD

View PDF23 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

When the inventors of the present invention prepared a positive electrode active material by mixing metal fluorides and heat-treating the mixture according to the disclosure, a practical effect on high-temperature storage stability was observed, but the effect was limited to the effect on the surface of the particles and based on actual Performance is insufficient

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

no. 1 approach

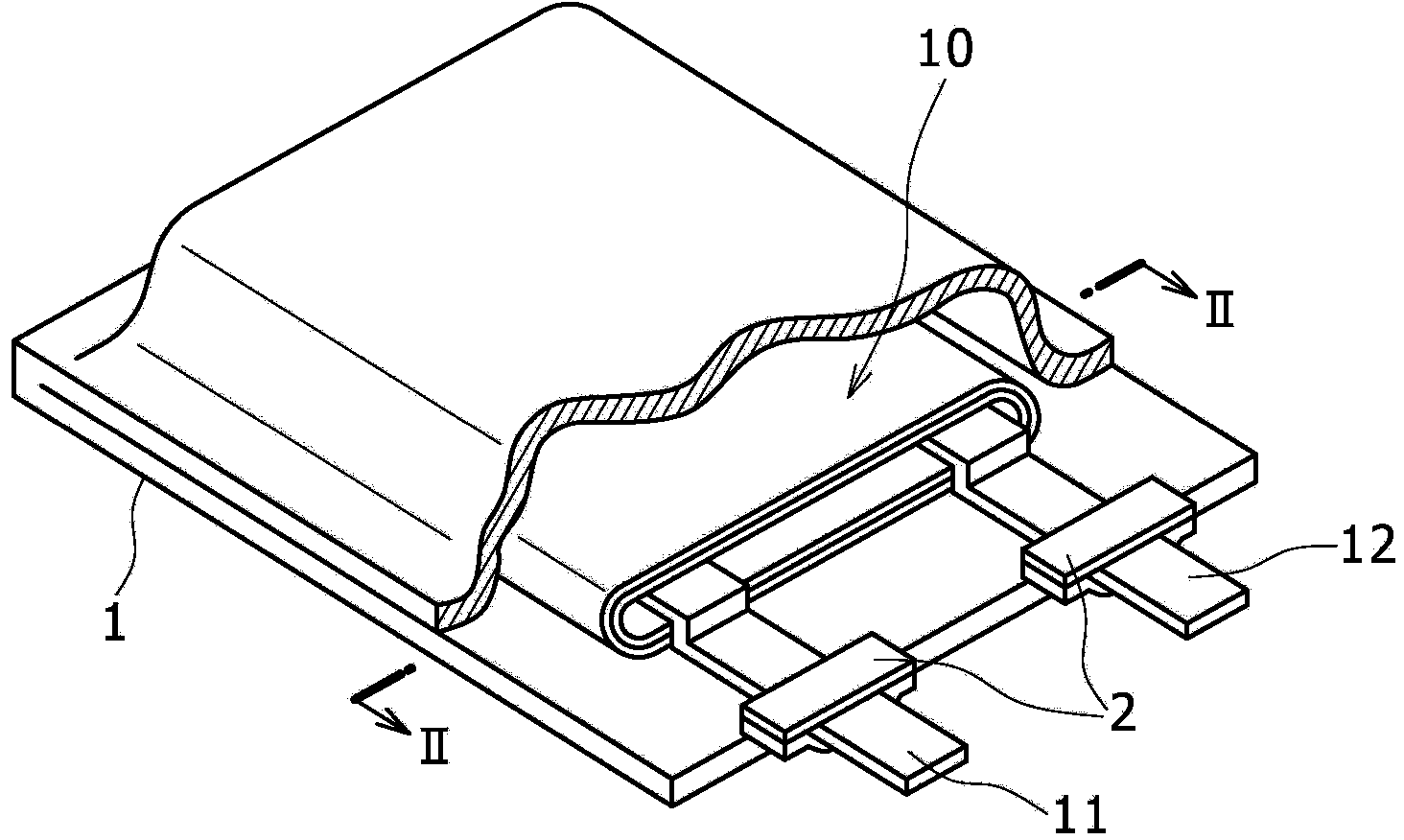

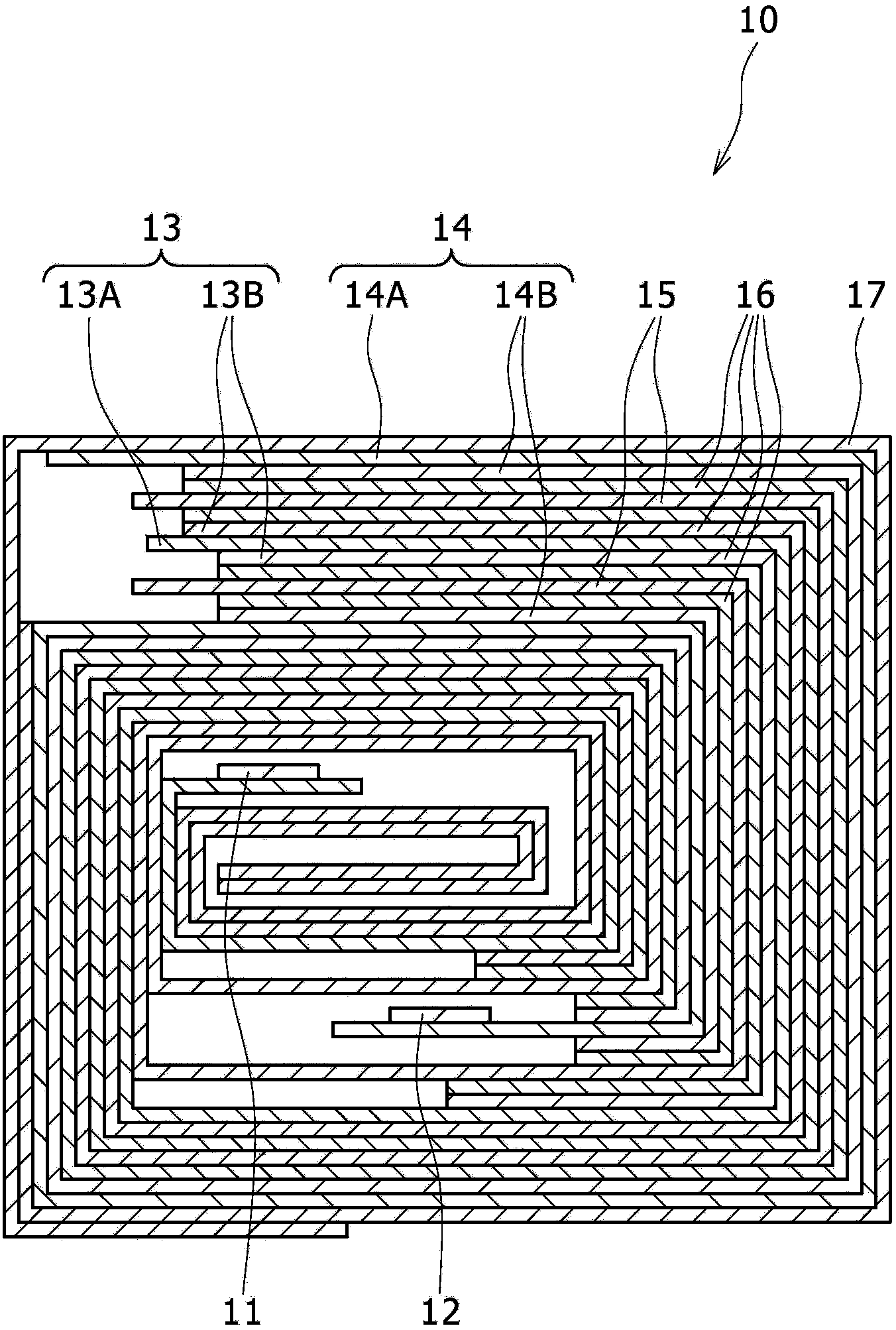

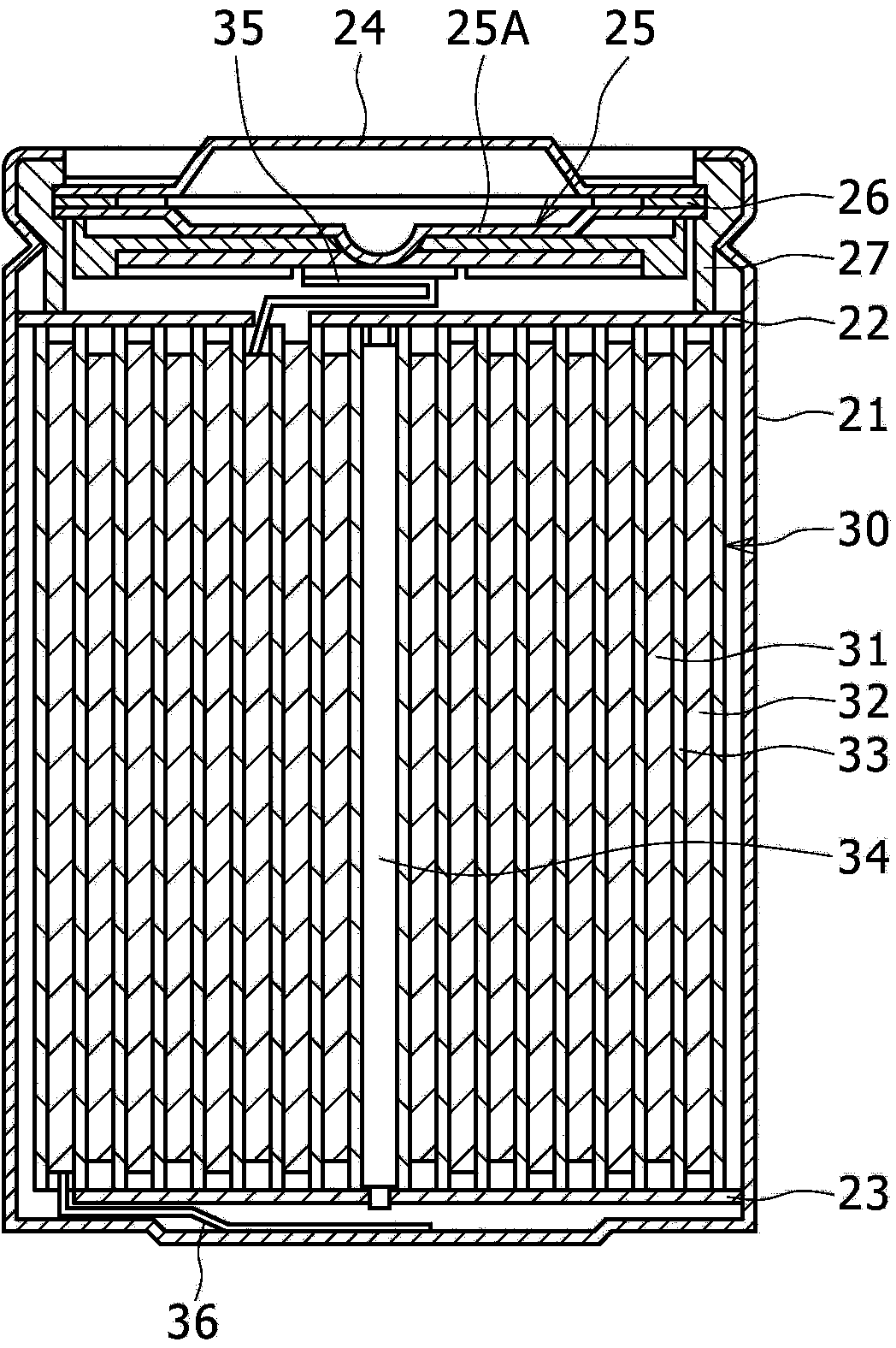

[0031] 1. First Embodiment (First Example of Nonaqueous Electrolyte Battery)

no. 2 approach

[0032] 2. Second Embodiment (Second Example of Nonaqueous Electrolyte Battery)

no. 3 approach

[0033] 3. Third Embodiment (Third Example of Nonaqueous Electrolyte Battery)

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Login to View More

Abstract

The invention provides a positive active material. The positive active material is prepared by the following steps: mixing lithium containing compound, compound containing transition metal which is contained in solid solution, and compound containing metallic element M2 which is different from the transition metal, sintering the compounds into mixture to form composite oxide particles, depositing compound selected from at least one element of sulphur, phosphorus, and fluorine on the surface of the composite oxide particle, and sintering composite oxide particles containing at least one element selected from sulphur, phosphorus, and fluorine on the compound. Thus, each composite oxide particle has such concentration gradient: concentration of the metallic element M2 increases from the center of the composite oxide particle towards the surface, and at least one element selected from at least one element of sulphur, phosphorus, and fluorine exists on the surface of the composite oxide particle in a gathering manner.

Description

[0001] This application is a divisional application of an invention patent application with an application date of September 9, 2010, an application number of 201010279232.7, and an invention title of "positive electrode active material and its preparation method, positive electrode and non-aqueous electrolyte battery". technical field [0002] The invention relates to a positive pole active material, a positive pole, a nonaqueous electrolyte battery and a method for preparing the positive pole active material. More particularly, the present invention relates to a positive electrode active material, a positive electrode, a nonaqueous electrolyte battery and a preparation thereof by which a nonaqueous electrolyte battery having high performance and exhibiting little capacity degradation can be realized when charging and discharging are performed in a high temperature environment Method of positive active material. Specifically, the present invention relates to a positive electr...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): H01M4/485H01M4/1391H01M10/05

CPCC01G51/006C01G51/42C01P2002/50C01P2002/52C01P2004/20C01P2004/54C01P2004/61C01P2004/80C01P2006/40H01M4/131H01M4/1315H01M4/1391H01M4/485H01M4/505H01M4/525H01M10/052H01M2004/021Y02E60/10

Inventor 森田耕诗细谷洋介藤木聪本桥一成李国华远藤一显

Owner MURATA MFG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com