Compaction device for a spinning machine

A spinning machine and compression unit technology, which is applied in spinning machines, spinning machines with continuous winding, textiles and papermaking, etc., can solve the problem of inflexibility of the pinch roller, and achieve compact structure and compact structure unit Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

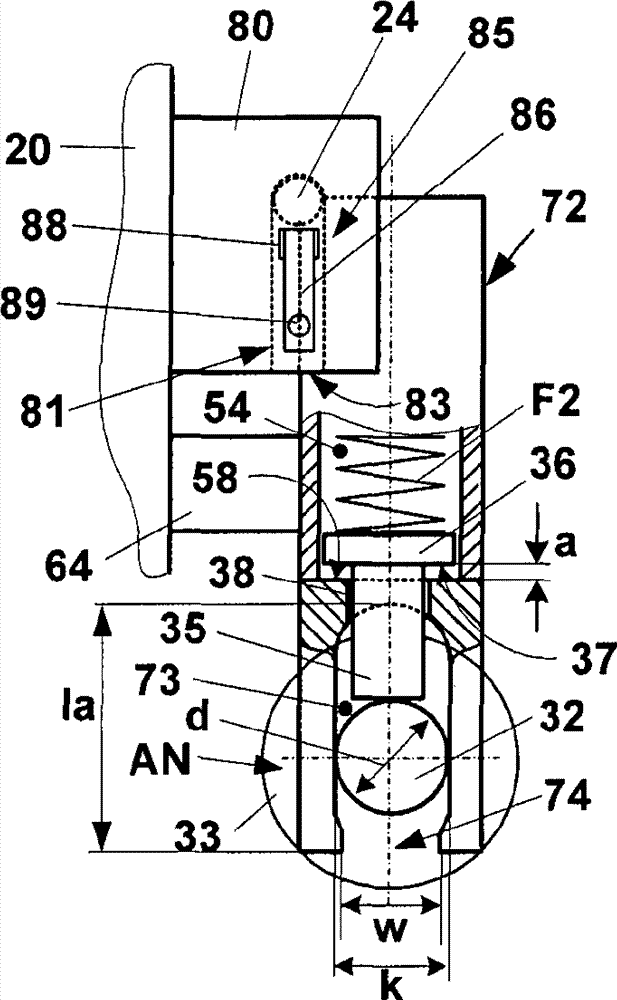

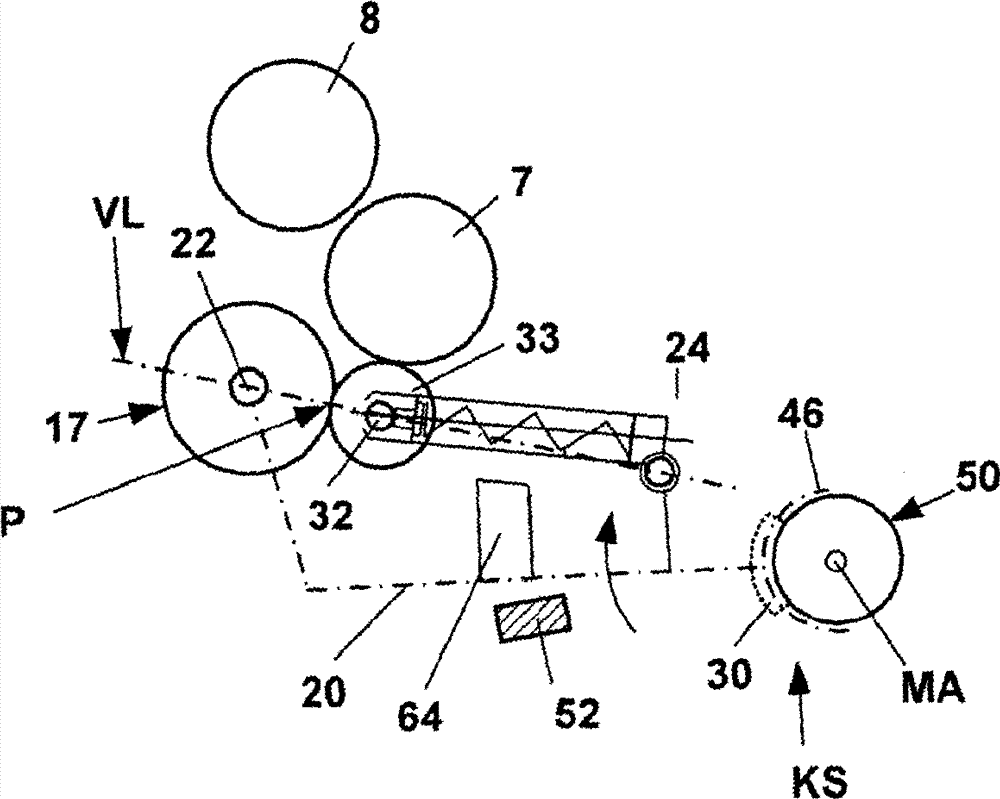

[0026] figure 1Shows a schematic side view of the spinning position 1 of a spinning machine (ring spinning machine) with a drafting unit 2 with a pair of input rollers 3, 4, a pair of intermediate rollers 5, 6 And an output roller pair 7,8. An apron 12 , 13 is each guided around the intermediate rollers 5 , 6 and is held in the position shown in each case around a cage (not shown in detail). The upper rollers 4 , 6 , 8 of the pair of rollers are designed as pressure rollers, which are rotatably mounted via axles 4 a , 6 a , 8 a on a pivotably mounted pressure rod 10 . The pressure lever 10 is mounted pivotably about an axle 15 and, as shown schematically, is loaded via a spring element F. FIG. The spring element can also be, for example, an air hose. The rollers 4 , 6 , 8 are pressed against the lower roller 3 , 5 , 7 of the roller pair via a schematically indicated spring load in order to form a clamping point for the fiber product. The roller pairs 3 , 5 , 7 (not shown) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com