Stamping multi-station die for medium-sized automobile parts and its operation method

A multi-station and mold technology, applied in the field of stamping and forming, can solve the problems such as the high cost of stamping parts for the overall model, the waste of the overall tonnage of the model mold, and the shortage of stamping machine resources, so as to reduce storage space requirements and save mold costs. investment and the effect of reducing the number of operators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

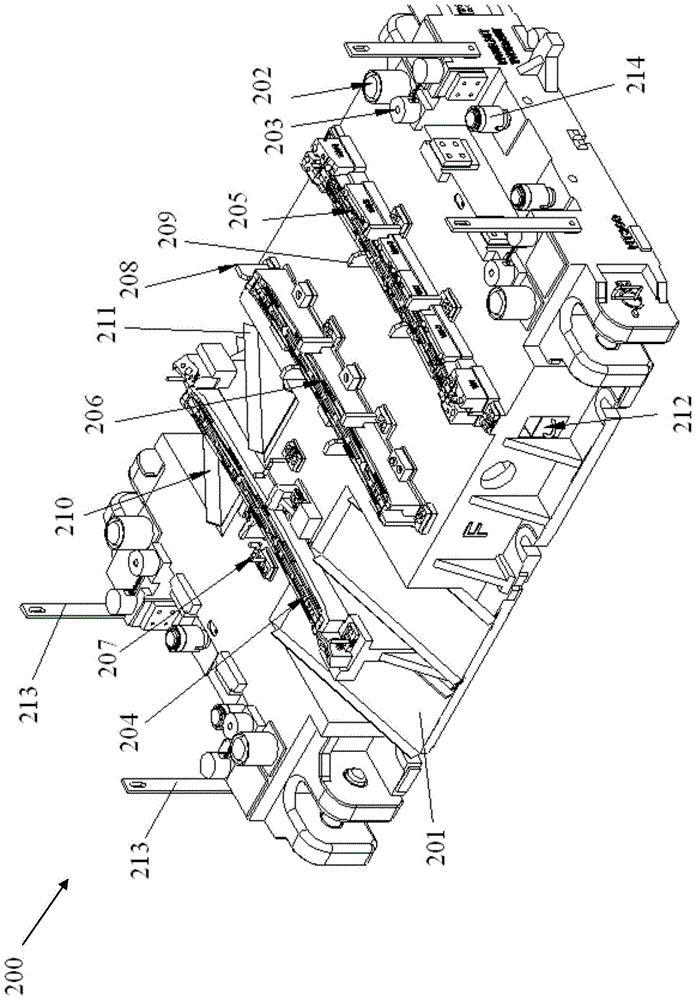

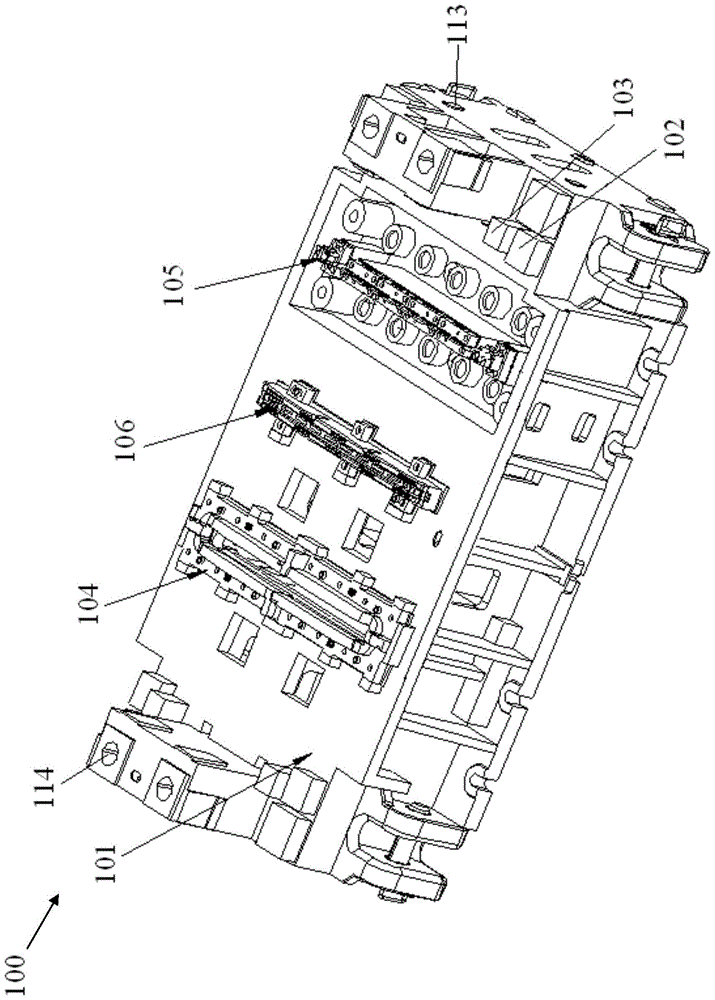

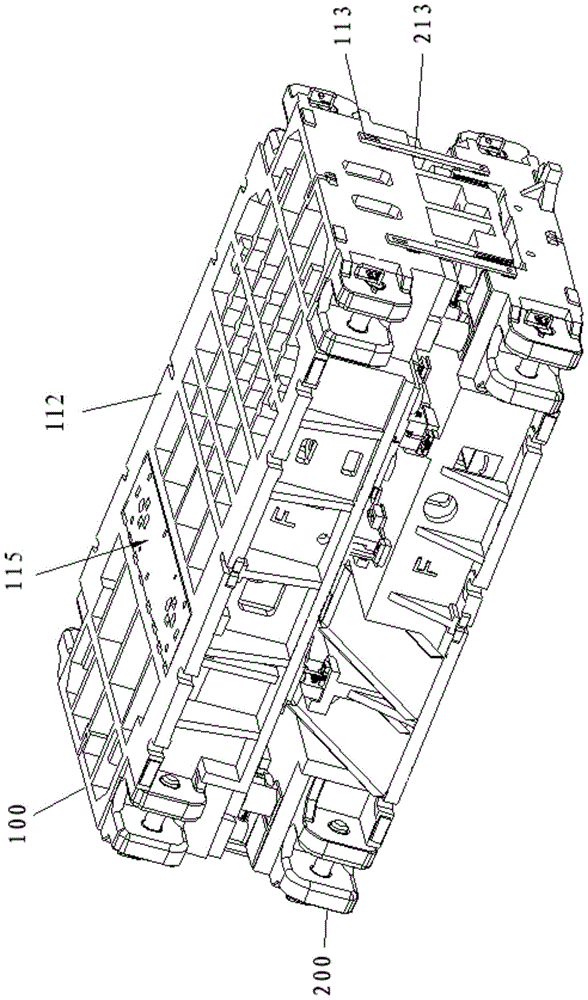

[0029] Such as figure 1 , 2 As shown, the stamping multi-station mold of the automobile medium-sized part comprises an upper mold 100 and a lower mold 200, the upper mold 100 comprises an upper mold base 101, and the lower mold 200 comprises a lower mold base 201, and the upper mold base 101 and the lower mold base 201 are all provided with There are trimming stations, punching stations, and shaping stations. The trimming stations include trimming positioning structures and trimming tools. The punching stations include punching positioning structures and punches. The shaping stations include shaping positioning structures and trimming tools. Shaping tool, trimming station and punching station are located on both sides of the shaping station. The stroke of the upper die when the trimming tool starts to work is smaller than the stroke of the up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com