Method for drilling high-precision large-aperture hole in printed board

A hole processing method and large-aperture technology, applied in the field of aperture processing, can solve the problems of large load resistance of the drill bit, large drilling error, serious drill bit shaking, etc., and achieve the effect of improving precision and product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

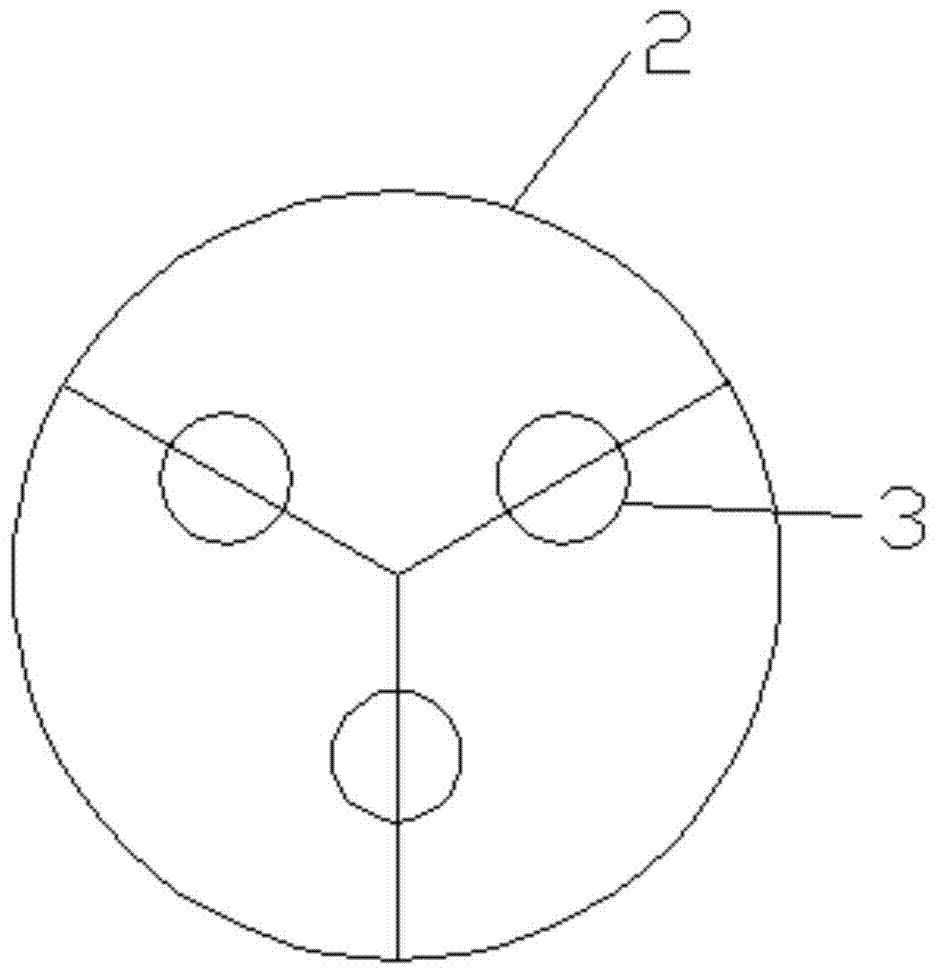

[0021] Such as figure 1 As shown, a large-aperture hole 2 with a diameter of 6.0 mm is drilled on a printed board 1, and the straight drilling method is used: first, the position of the large-aperture hole to be drilled on the printed board is located at the position of the large-aperture hole On the midpoints of the three radiuses that form an angle of 120 degrees with each other, drill a first guide hole 3 respectively. The diameter of the first guide hole is 2.0mm; Drill the hole. When selecting a drill bit, you can choose according to the expansion and contraction coefficient of the material. If the expansion and contraction coefficient of the material is greater than 1, choose a drill bit that is slightly smaller than the diameter of the large hole to be drilled. The drill bit with a large aperture and a slightly larger diameter is to be drilled, which just compensates for the error caused by the expansion and contraction of the material and improves the drilling accurac...

Embodiment 2

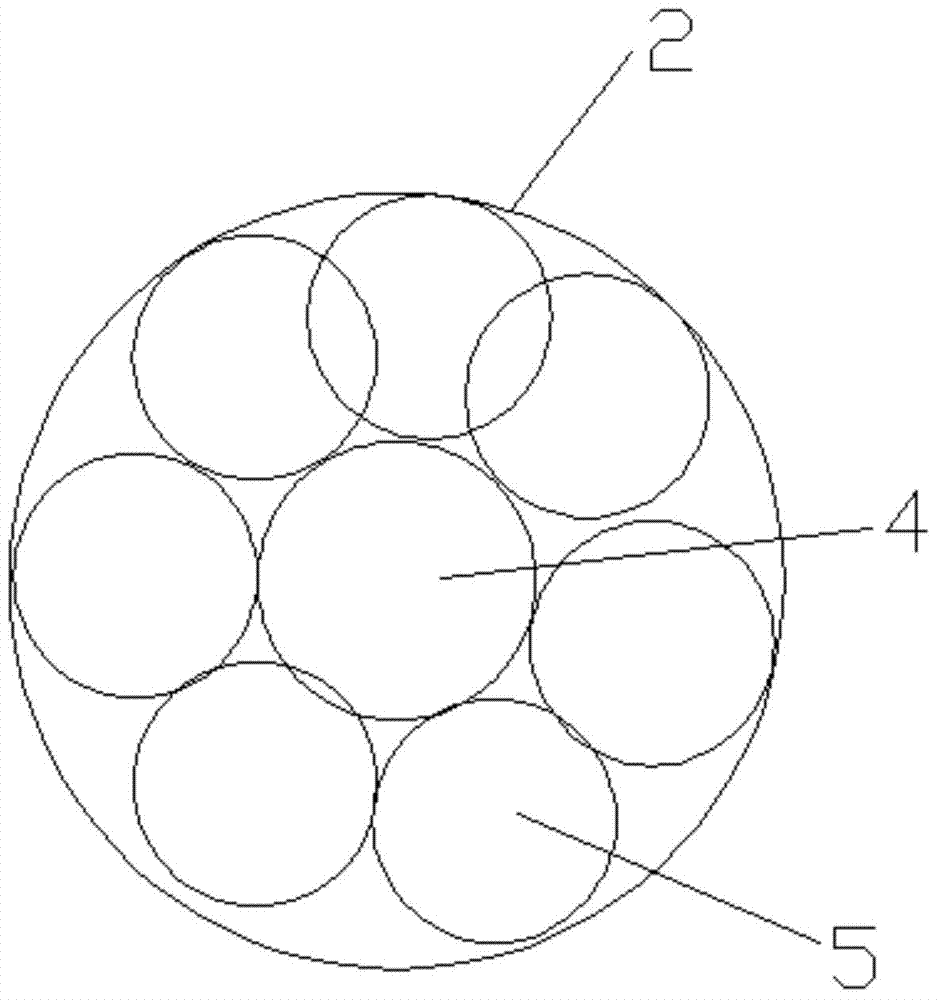

[0023] Drill a large-aperture hole 2 with a diameter of 9.0mm on a printed board, using the expansion drilling method: first drill a second guide hole 4 at the center of the large-aperture hole 2 to be drilled, and then drill the second guide hole 4 Drill several reaming holes 5 at intervals between the large aperture hole 2 to be drilled, and the diameter of the reaming hole is 1 / 3 of the large aperture hole to be drilled, i.e. 3.0mm, wherein the diameter of the second guide hole is according to the formula : Calculated by D-2d+0.1mm, where D is the diameter of the large hole to be drilled, and d is the diameter of the expanded hole. Through calculation, the diameter of the second guide hole is 3.1 mm. The expansion drilling method firstly drills the second guide hole, and then drills and expands the hole to finally form the required large-diameter hole. The drilling process reduces the load resistance and reduces the shaking and swing of the drill bit during drilling, thus b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com