Cutting torch nozzle follow-up protection mechanism

A protection mechanism and follow-up technology, applied in the direction of welding/cutting auxiliary equipment, auxiliary equipment, plasma welding equipment, etc., can solve the problems of cutting torch damage, affecting work efficiency, contact, etc., to achieve protection safety, simple and compact structure, Avoid the effect of accidental impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

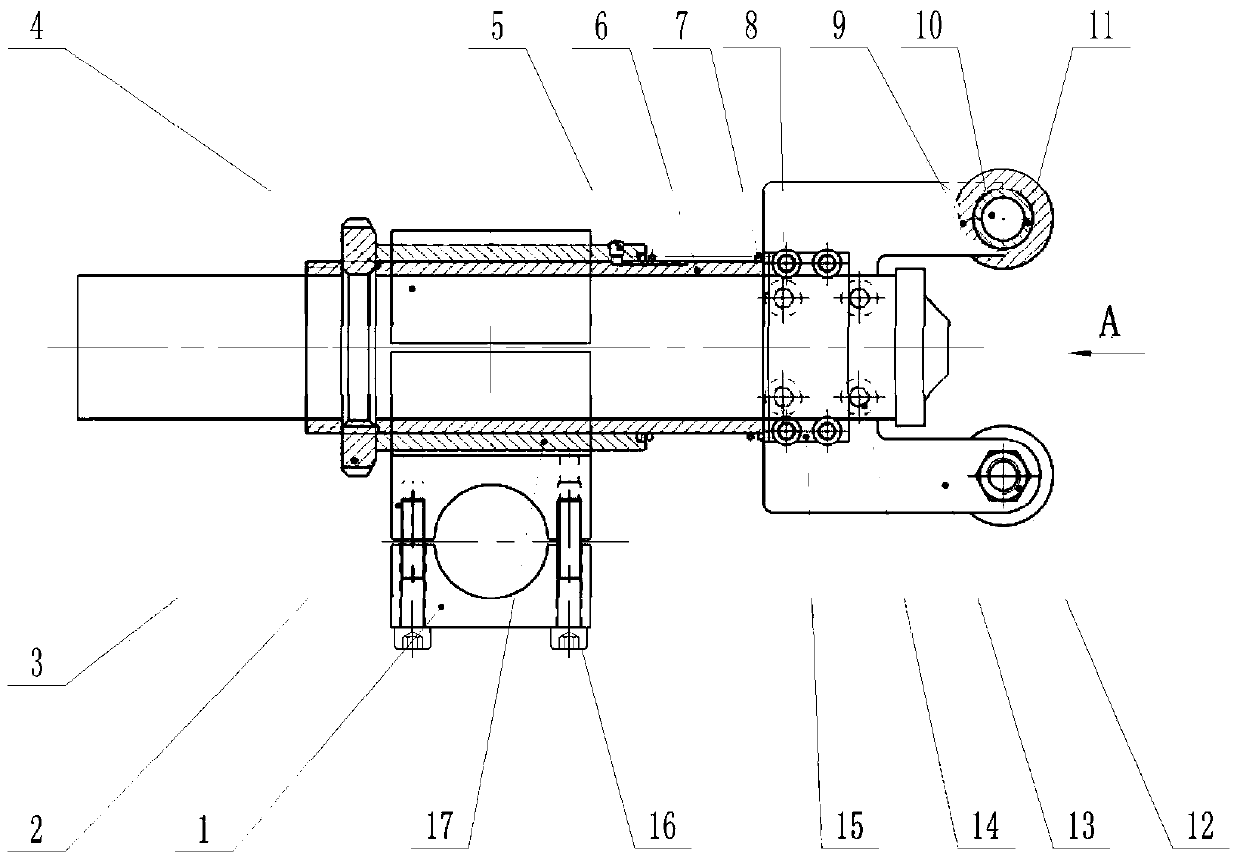

[0013] See figure 1 , The present invention includes a torch bracket composed of a pressure plate I1, an intermediate plate 2 and a pressure plate II4, a follower support 6, a positioning sleeve 17, a return spring 7, a baffle 13, a buckle cover 15, a support wheel 9, a pin shaft 10, Copper sleeve 11 etc. The positioning sleeve 17 is fixed on the torch bracket, and the threaded hole at the front end is equipped with a positioning screw 5. The follower bracket 6 is composed of a sleeve and a semicircular buckle cover. The sleeve part is sleeved on the torch and inserted into the positioning In the sleeve 17, a thread is tapped at the end of the sleeve, and a positioning round nut 3 is installed on the thread. One end of the return spring 7 is placed at one end of the positioning sleeve 17, and the other end is in contact with one end of the semicircular buckle cover of the follower bracket 6.

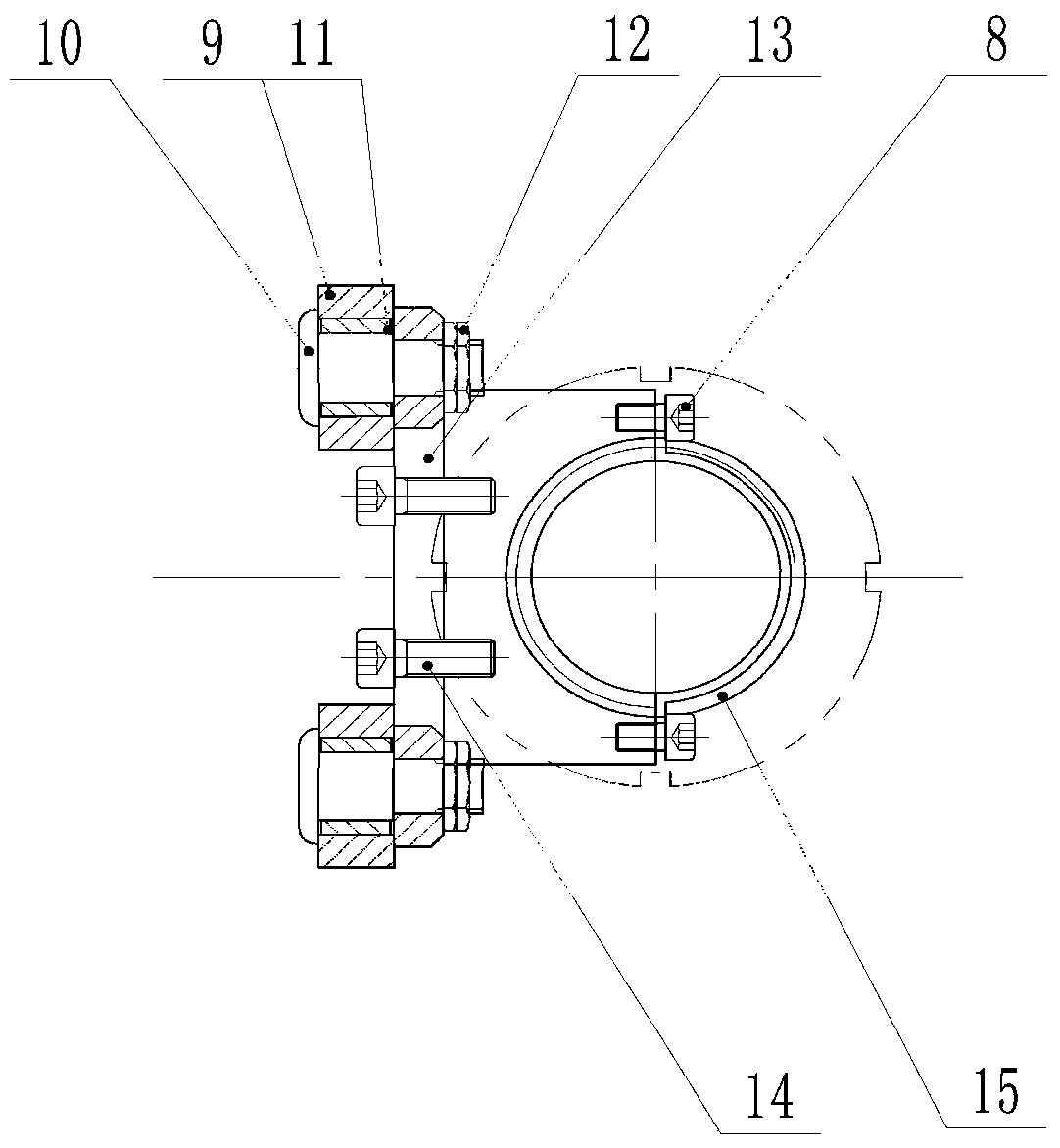

[0014] See figure 2 , The support wheel 9 embedded with the copper sleeve 11 is hing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com