Aluminum alloy stirring friction welding defect repairing method

A welding defect and friction stirring technology, which is applied in welding equipment, welding/welding/cutting items, non-electric welding equipment, etc., can solve problems such as broken stirring needles and buried stirring needles, and achieves simple operation, strong practicability and economy high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

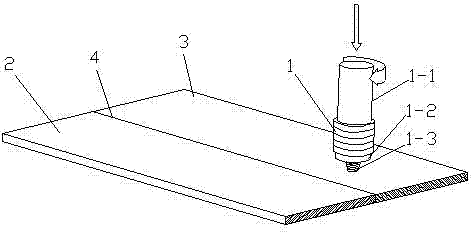

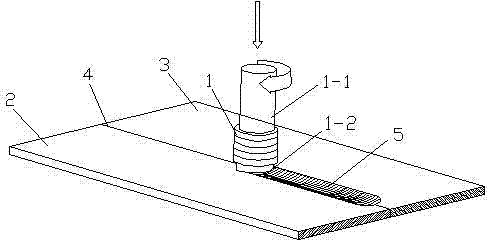

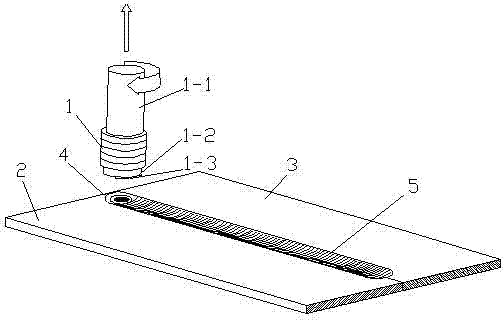

[0022] combine figure 1 , figure 2 , image 3 and Figure 4 , the aluminum alloy workpiece 2 to be welded and the aluminum alloy workpiece 3 are both 6082 aluminum alloy plates with a plate thickness of 12mm (heat treatment state is T6). The oxide film on the upper surface and side of workpiece 2 and workpiece 3, and then achieve a good combination between workpiece 2 and workpiece 3. The stirring head 1 used is composed of a clamping area 1-1, a shaft shoulder 1-2 and a stirring pin 1-3. Set the axial direction of the stirring head 1 and the surface normal direction of the aluminum alloy workpiece 2 and workpiece 3 to be welded to form a forward inclination angle of 2.5°. Start the friction stir welding equipment so that the stirring head 1 reaches a set speed of 450 rpm. The stirring head 1 penetrates into the weld seam 4 between the aluminum alloy workpiece 2 and the workpiece 3 to be welded at a speed of 0.3mm / s until the shoulder 1-2 of the stirring head 1 is presse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com