A car interior rearview mirror

An interior rear-view mirror and automobile technology, applied in the field of auto parts, can solve the problems of mirror shell and mirror seat locking failure, affecting life safety, abnormal collision noise, etc., so as to improve secondary maintainability, avoid vision, reduce the effect of complaining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with accompanying drawing.

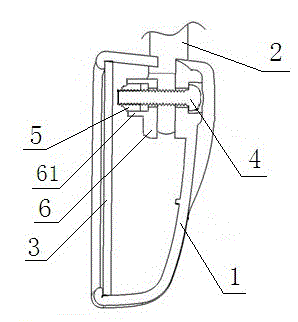

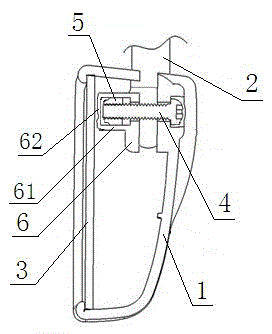

[0011] Such as figure 2 The automobile interior rearview mirror shown includes a mirror base 2, a mirror housing 1, a lens 3 mounted on the mirror housing 1, and a connecting bracket 6 integrally formed with the mirror housing 1, and the mirror housing 1 and the connecting bracket 6 are both plastic parts , the connecting bracket 6 is located in the cavity formed by the lens 3 and the mirror case 1, and the connecting bracket 6 is provided with a hexagonal anti-loose boss 61, and is provided with connecting holes and bolt holes for the mirror base, and the anti-loose boss is provided with a useful To accommodate the groove of the lock nut 5, the depth of the groove is 5mm (or 4mm, 7mm) longer than the length of the lock nut 5, the end of the mirror base 2 is inserted into the connecting hole of the mirror base, and the bolt 4 (hexagonal Fully threaded bolts) are inserted ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com