Vibration discharging device of rubbish slurry

A vibrating discharge device and mud technology, applied in the directions of transportation and packaging, conveyor objects, etc., can solve the problems of sticky wall blockage and high moisture content of mud-like garbage, and achieve the effects of high strength, simple structure and fast discharge.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

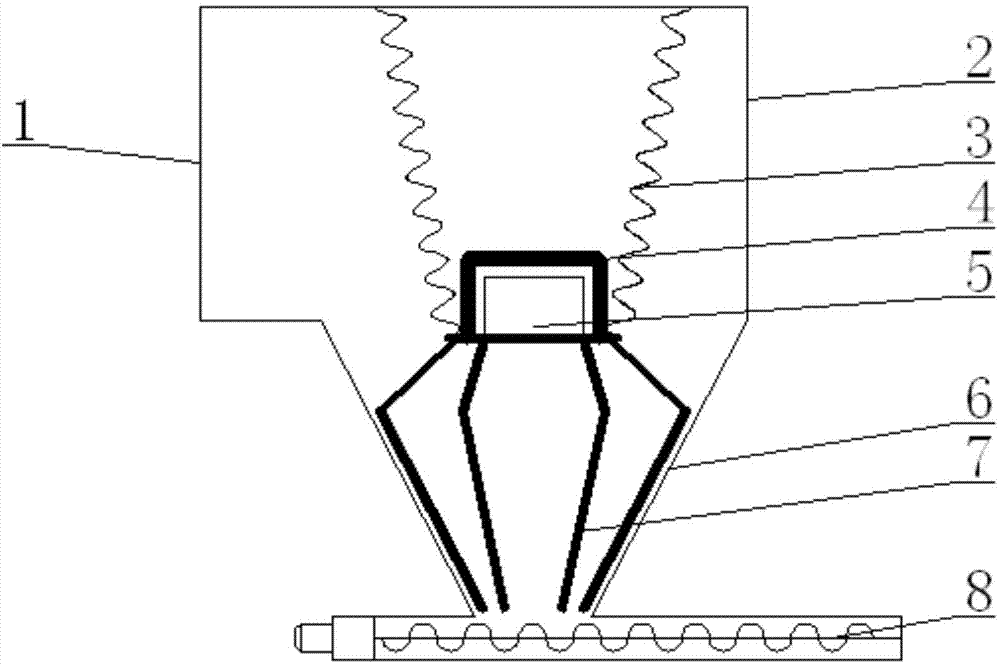

[0013] A vibrating discharging device for garbage slurry, the vibrating discharging device includes an anti-punching silo 2, on one side of the anti-punching silo, a slurry-like garbage steam ejection inlet 1 is formed, and at the lower part of the anti-punching silo Slurry garbage steam ejection outlet 6 is formed, and a vibration motor 5 is arranged in the anti-punching silo above the muddy garbage steam ejection outlet. A protective cover 4 is installed outside the vibration motor. The vibration motor passes through a spring 3 Connect the anti-punching silo, and connect a vibrating steel claw 7 under the vibrating motor. The vibrating steel claw is set in the discharge port of the steam ejection of muddy garbage. There are 10 bending claw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com