Microalgae continuous reaping device and method

A harvesting device and technology for microalgae, applied in biochemical equipment and methods, enzymology/microbiology devices, biochemical cleaning devices, etc., to achieve the effect of simple technical principle, convenient processing, and promotion of large-scale cultivation and industrialization of microalgae

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

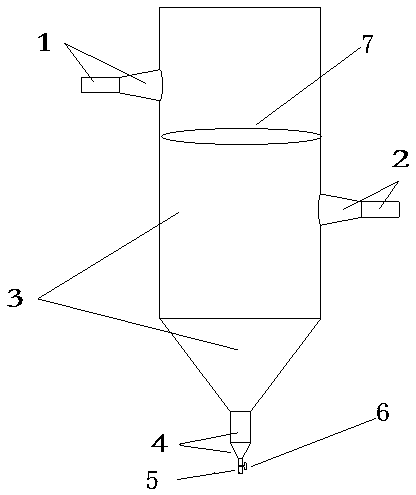

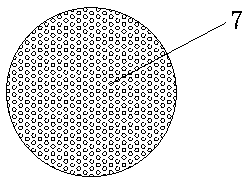

[0021] A microalgae continuous harvesting device, comprising a settling column 3, a concentration column 4 with a smaller diameter than the settling column is connected below the settling column 3, and an algae outlet pipe with a smaller diameter than the concentration column is connected below the concentration column 4 5. A valve 6 is installed on the algae outlet pipe 5; a water inlet 1 and a water outlet 2 are connected on the outer wall of the settling column 3, and the water inlet 1 is higher than the water outlet 2, and is fixed on the inner wall of the settling column 3 There is a porous energy dissipation basin 7, and the position of the energy dissipation basin 7 is between the water inlet 1 and the water outlet 2. like figure 1 shown.

[0022] The settling column 3 is composed of a settling tube and a settling transition tube. The settling tube is made of transparent organic glass with a diameter of 400 mm and a length of 1000 mm. Made of glass, the length is 20...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com