A method and device for adjusting and controlling the liquid soup of an automatic silk reeling machine

A silk reeling machine, automatic technology, applied in the direction of silk reeling, etc., can solve the problems of increasing the amount of transportation costs, waste water treatment costs, poor temperature control effect, clogged nozzles, etc., to improve the effective threading rate and high temperature control efficiency , reduce the effect of depression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

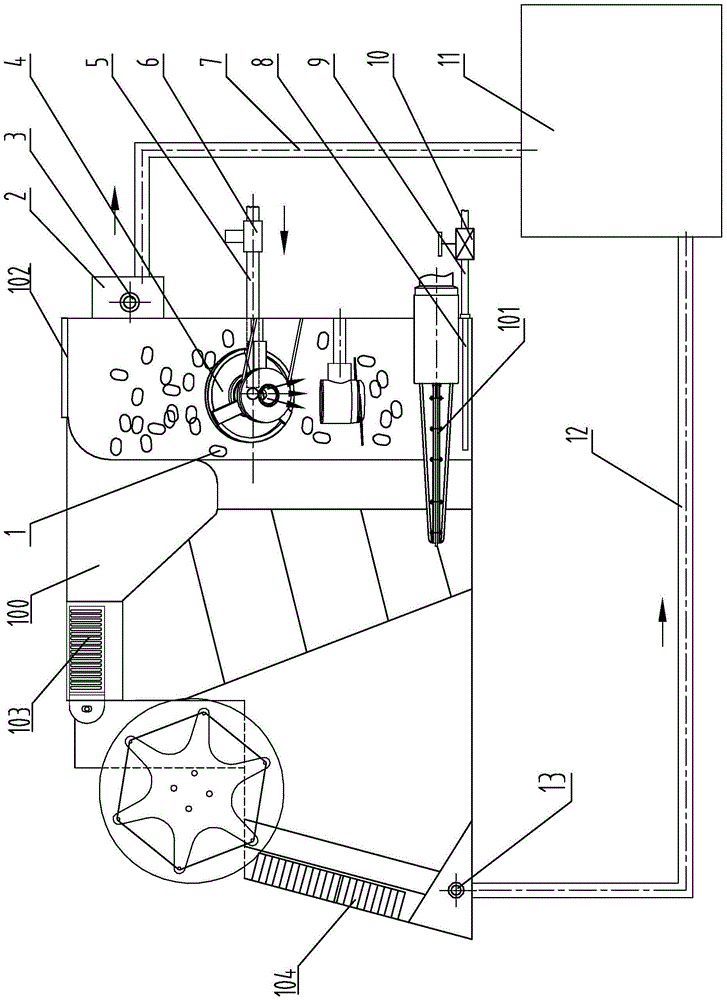

[0015] Such as figure 1 , 2 shown. An eccentric plate threader 4 and a fine silk transfer device 101 are arranged above the threader pot 100 of the automatic silk reeling machine, and reference number 102 is the threaded cocoon and the cocoon mouth of the threader pot, and the cocoon of the threader pot comes from the The port enters the thread-free pot, and the reference number 103 is the return port of the thread-free cocoon of the thread-free pot, and the thread-free cocoon in the thread-free pot is sent back to the cable thread of the thread-free pot through the mouth; the reference number 104 is the addition of the thread-free pot The cocoon mouth, the Zhengxu cocoon after tidying up is added to the cocoon machine through this mouth.

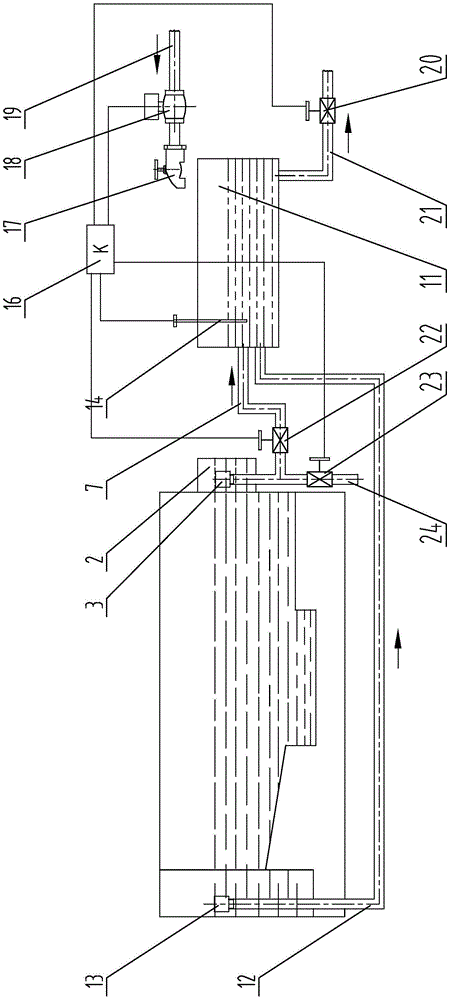

[0016] After analysis and testing, although there is a soup water circulation system in the Lixu pot, the temperature of the soup in the Lixu pot can be cooled by supplementing water, but the temperature of the soup in the Lixu pot is not...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com