Angular contact ball bearing

An angular contact ball bearing and bearing technology, applied in the field of bearings, can solve problems such as the inability to effectively adjust the distance between two rows of steel balls, the inability to accommodate split cages, and the space limitation of hub bearing structures, so as to improve toughness and rigidity , the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

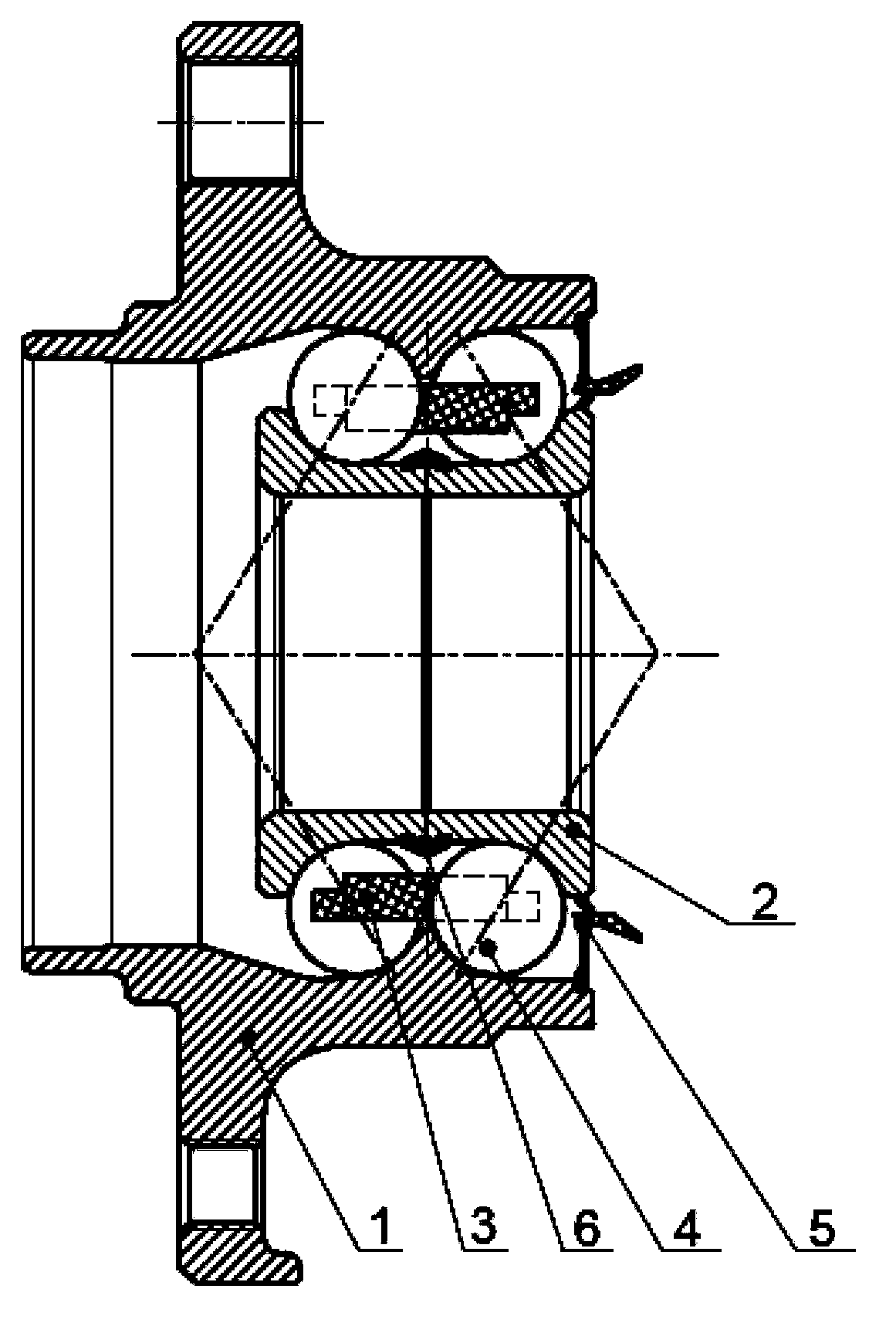

[0027] Such as figure 1 As shown, an angular contact ball bearing includes a flanged outer ring 1, two inner rings 2, two cages 3, several steel balls 4, a sealing ring 5, and a locking buckle 6. The inner ring 1 and the outer ring 2 form a double-row channel matching the steel ball 4, the cage 3 evenly distributes the steel ball 4 in the channel, and the sealing ring 5 is arranged between the outer ring and the inner ring Grooves are provided on the outside of the small end faces of the two inner rings 2, and the lock buckle 6 is arranged on the grooves of the two inner rings to fix the two inner rings. Grease is applied to the grooves of the inner and outer rings.

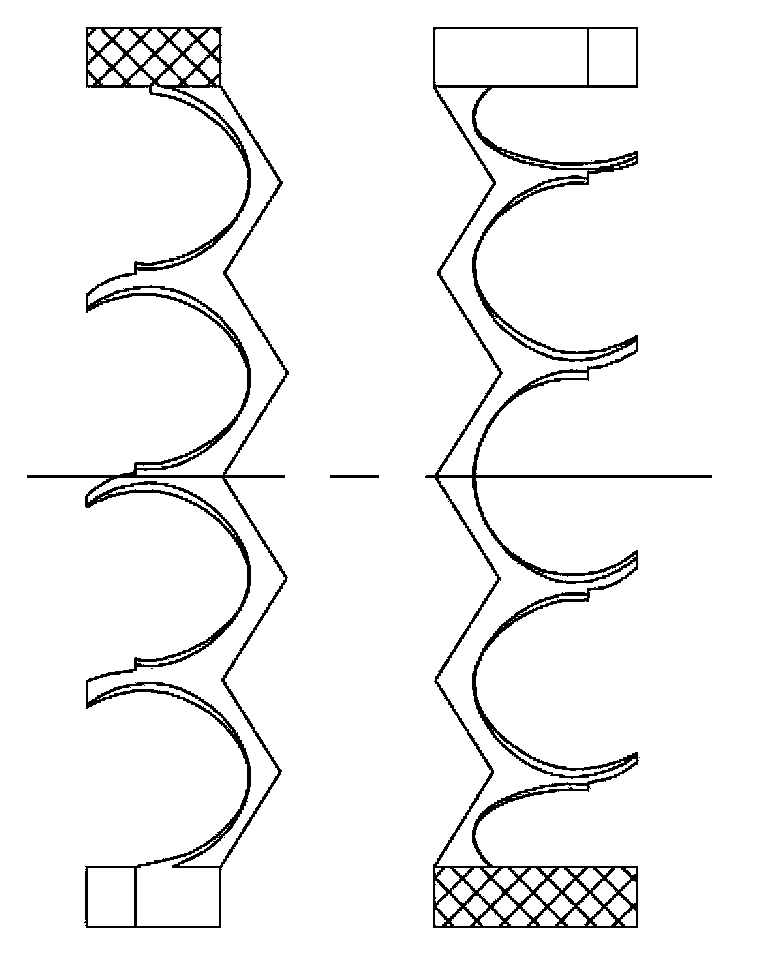

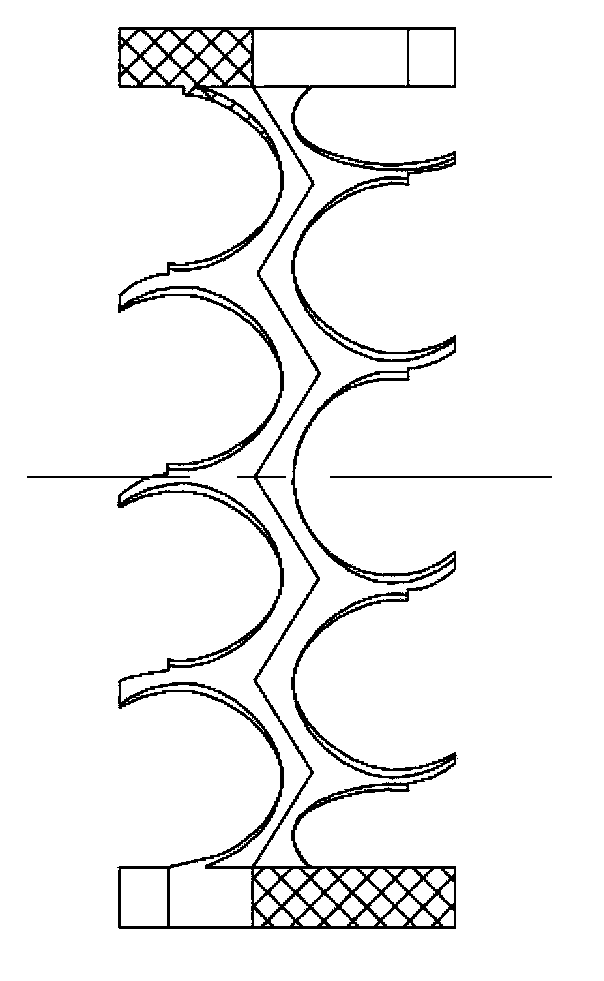

[0028] Such as Figure 2-3 As shown, the non-steel ball side of the cage is designed with several "V" grooves, which are consistent with the number of cage pockets and staggered with each other. After the bearing is assembled, the two cages are installed back to back, " The V"-shaped grooves cross each other, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com