Combined bearing of paper machine

A combined bearing and paper machine technology, applied in the field of bearings, can solve the problem of large radial load and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

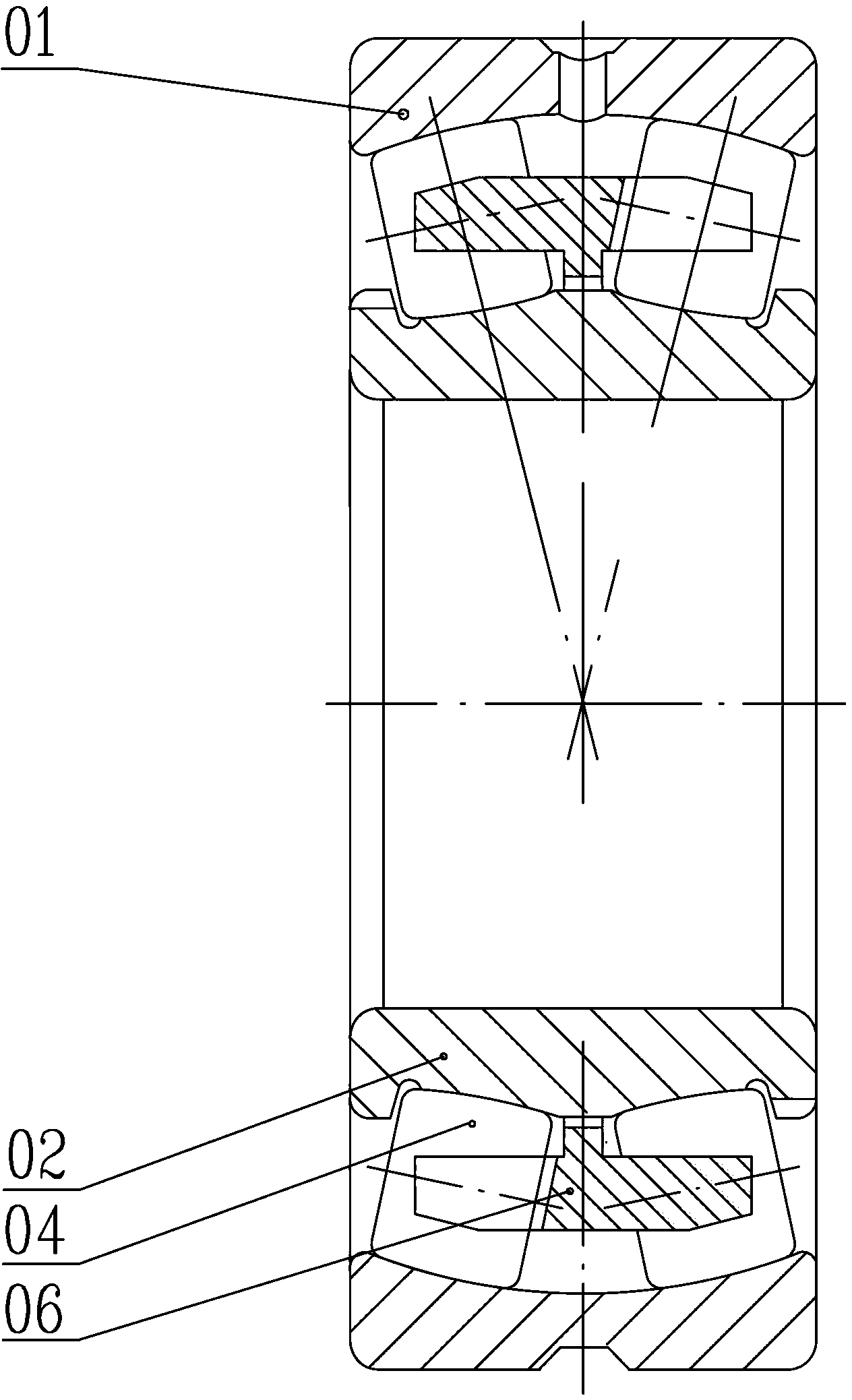

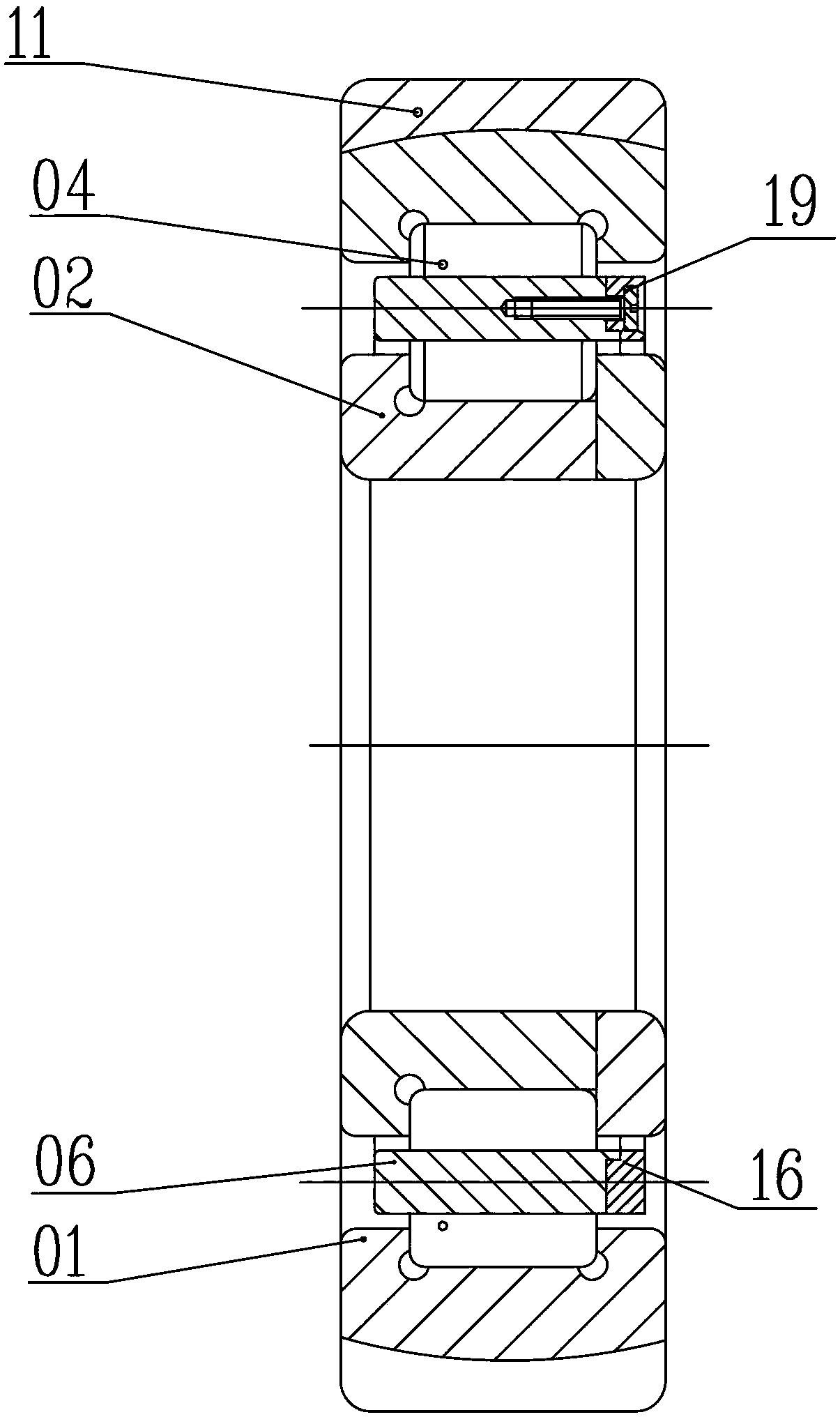

[0009] A composite bearing for a paper machine, including a three-ring bearing, a sliding bearing between the middle ring and the outer ring, and a rolling bearing with rollers between the middle ring and the inner ring. Self-aligning effect, the rolling bearing part plays the role of rotation in the main operation process of the bearing. Such as figure 2 As shown, it includes cylindrical head screw 19, cage cover 16, cage seat 06, roller 04, inner ring 02, middle and outer ring 01, and outer ring 11.

[0010] The above is only a preferred embodiment of the present invention, but the scope of protection of the present invention is not limited thereto. Anyone familiar with the technical field within the technical scope disclosed in the present invention, according to the technical solution of the present invention Any equivalent replacement or change of the inventive concepts thereof shall fall within the protection scope of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com