Double-row cylindrical roller split bearing with spherical outer ring

A technology of cylindrical roller and split bearings, which is applied in the field of bearings, can solve the problems of reduced work efficiency, no self-aligning effect, and difficulty in replacing bearings, and achieve the effects of reducing time and costs, improving the lubrication environment, and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

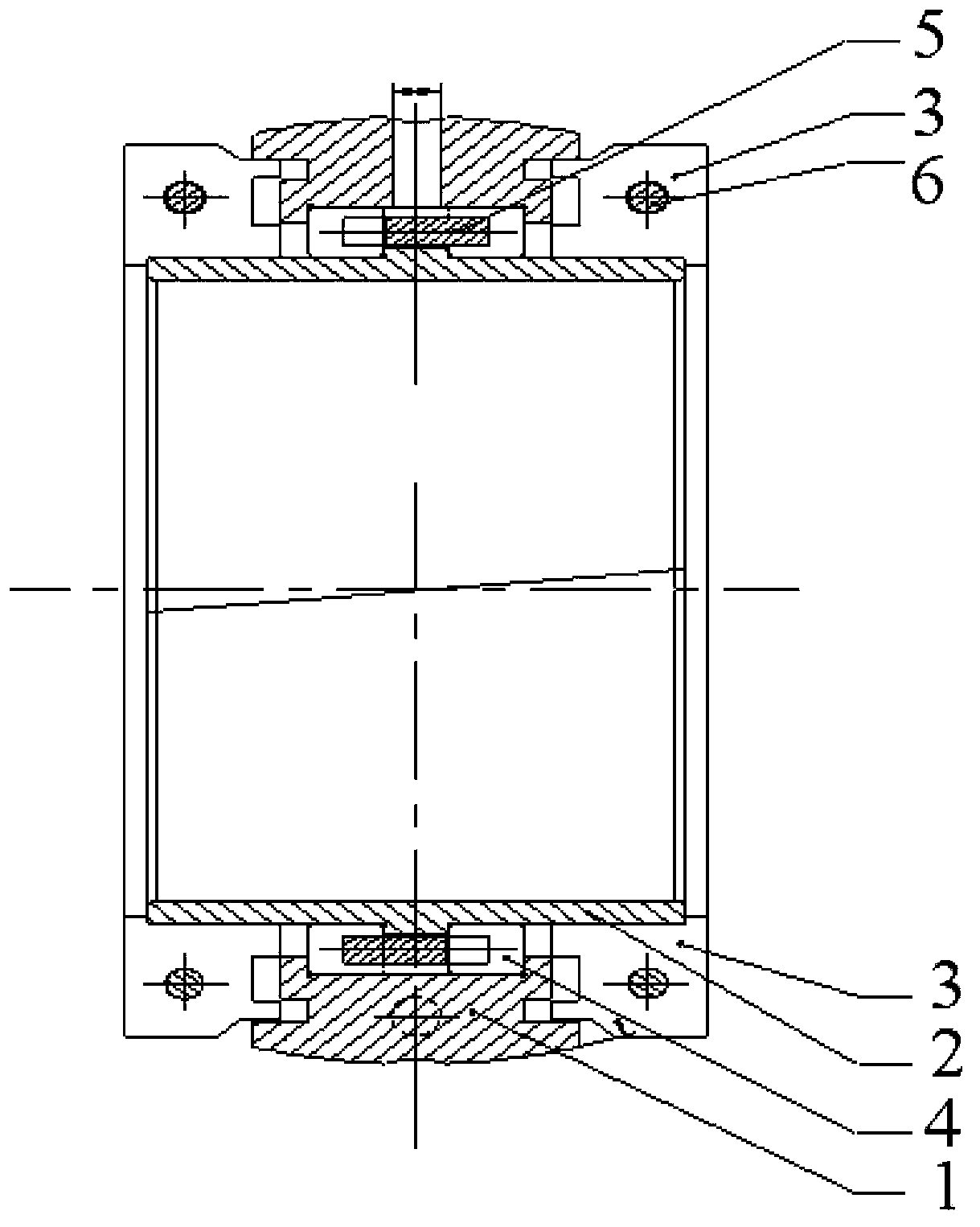

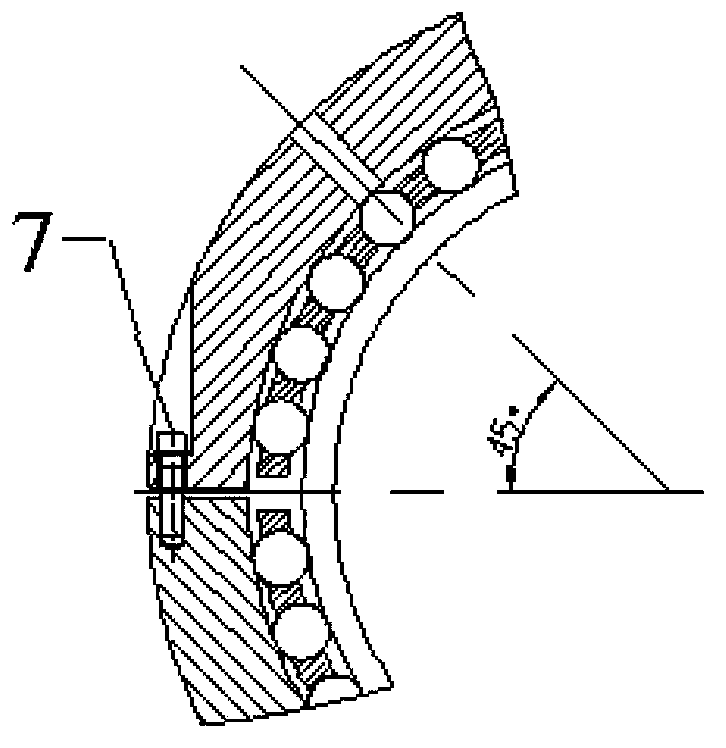

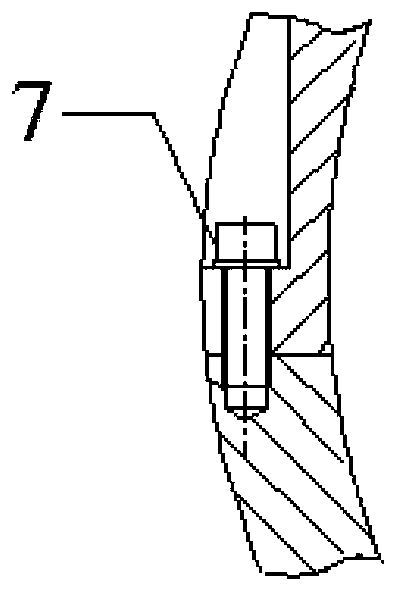

[0024] A split bearing with spherical double row cylindrical rollers on the outer ring, its structure is as follows figure 1 As shown, it includes two double half outer rings 1, two double half inner rings 2, two inner ring half fasteners 3, rollers 4, two half cages 5, four inner ring fastening screws 6, Four inner ring tight springs, two outer ring fastening screws 7, two outer ring fastening springs, the outer ring is composed of two double half outer rings 1 connected by outer ring fasteners, the thickness of the outer ring is 24mm, Increased strength The inner ring is composed of two double-half inner rings 2 connected, the inner wall of the outer ring and the outer wall of the inner ring form a double-row raceway, and the rollers 4 are set in the double-row raceway through the two half-cages 5 .

[0025] Roller 4 adopts cylindrical roller, and diameter increases, and roller increases, and roller diameter is 14mm, and length is 16mm, has increased bearing load, improves s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com