Integrated type inertia electromagnetic actuator

An electromagnetic actuator, integrated technology, applied in the direction of magnetic spring, spring/shock absorber, non-rotational vibration suppression, etc., can solve the problems of complex use, actuator does not consider the impact of performance, and continuous wire interference signal, etc. , to achieve the effect of compact structure, ensuring safety and reliability, long-term operation and reasonable response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

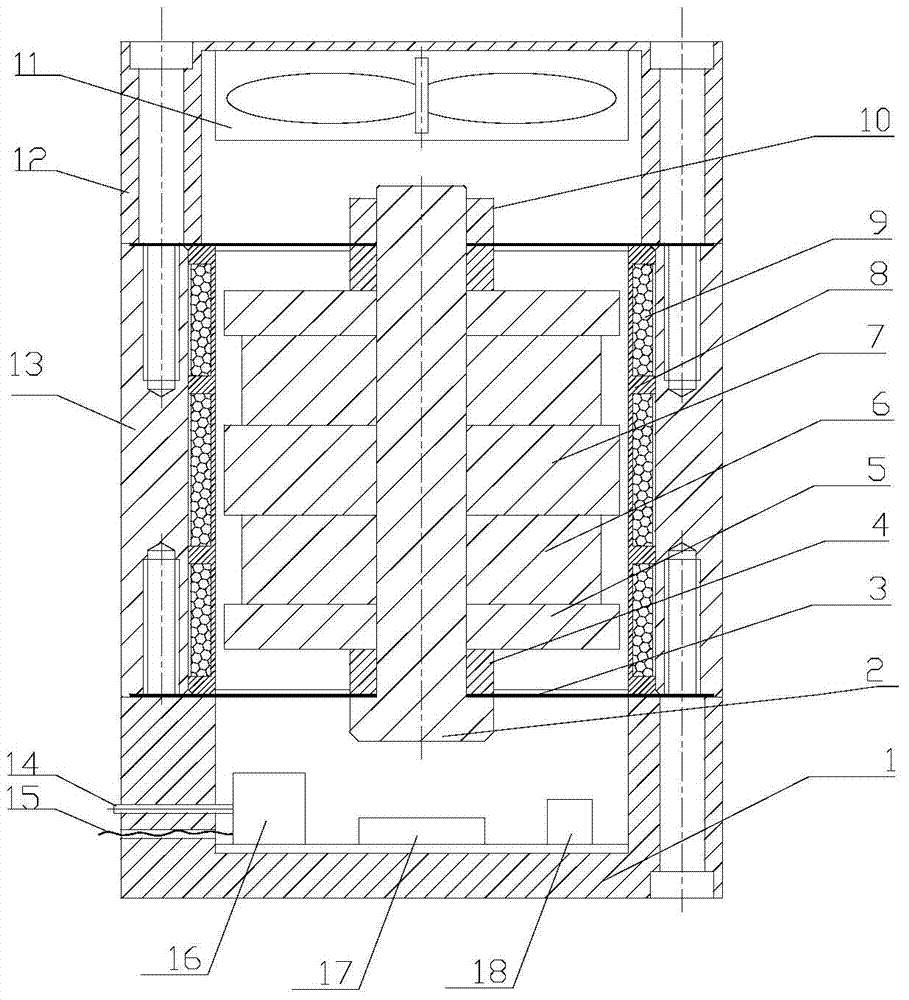

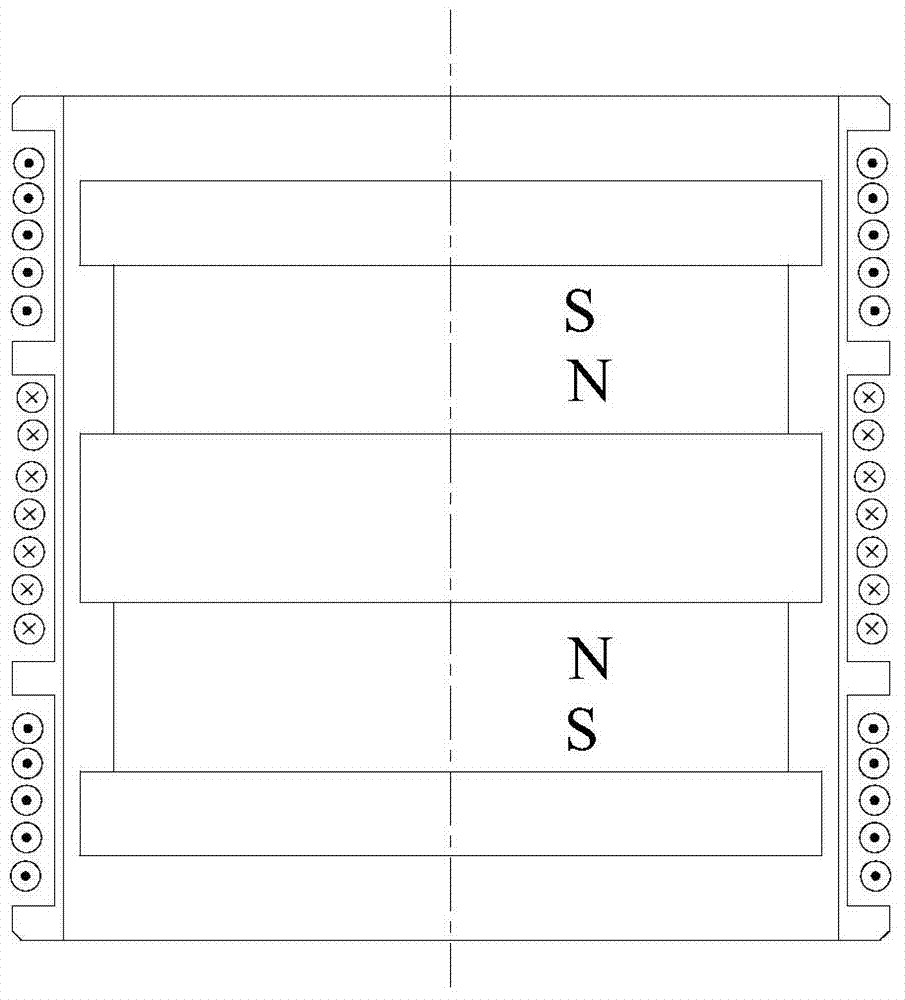

[0024] The actuator vibrator is composed of permanent magnet 6, intermediate magnetizer 7 and upper and lower magnetizers 5 connected by connecting bolts 2, gaskets 4 and nuts 10, and the outer magnetic cylinder 13, coil holder 8 and coil 9 form the periphery of the magnetic circuit The structure, the vibrator and the peripheral structure of the magnetic circuit are connected through the support plate spring 3, the vibrator and the peripheral structure of the magnetic circuit are the magnetic circuit structure of the entire inertial electromagnetic actuator, in which the magnetic circuits of the two permanent magnets are in opposite directions, and the upper and lower coils are connected to the middle coil. The winding direction is opposite; the DC fan is fixed with the upper end cover, and there is a vent on the upper end cover, and the upper end cover is connected with the leaf spring and the outer magnetic cylinder through 6 bolts; when the coil 9 is supplied with alternating...

Embodiment approach 2

[0026] combine Figure 1~4 , the actuator vibrator is formed by connecting the permanent magnet 6, the middle magnetizer 7 and the upper and lower magnetizers 5 through the connection bolt 2, the gasket 4 and the nut 10, and the outer magnetizer 13, the coil holder 8 and the coil 9 form a magnetic circuit Peripheral structure, the vibrator and the peripheral structure of the magnetic circuit are connected through the support plate spring 3, the peripheral structure of the vibrator and the magnetic circuit is the magnetic circuit structure of the entire inertial electromagnetic actuator, in which the magnetic circuits of the two permanent magnets are in opposite directions, the upper and lower coils and the middle coil The winding direction is opposite; the DC fan is fixed on the upper end cover, and there is a vent on the upper end cover, and the upper end cover is connected with the leaf spring and the outer magnetic cylinder by 6 bolts; the accelerometer 18 is fixed on the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com