Quick locking connector

A fast, locking technology, applied in mechanical equipment, couplings, etc., can solve the problems of oil and gas leakage, easy oil leakage or gas leakage, low performance of pipe expansion compensation, and achieve the effect of preventing leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

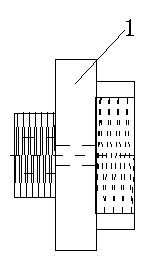

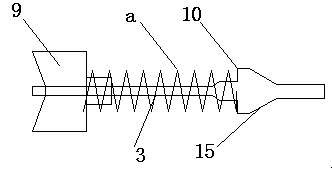

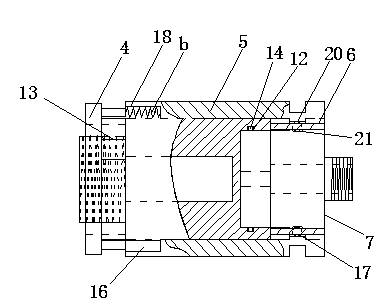

[0022] The quick joint with lock of the present invention comprises: left joint 1, right joint 2;

[0023] In order to make the quick joint with lock of the present invention have the functions of convenient connection and disassembly, reliable sealing, and automatic sealing after separation, the quick joint with lock of the present invention is added: left spool assembly 3, joint body 4, joint sleeve 5, single ring Bearing 6, ferrule 7, right spool combination 8, left spool 9, spring a, left thimble 10, support part 11, groove structure 12, circular concave-convex steel pipe with window 13, sealing ring 14, sealing part 15 , spring b, block structure 16, concave structure 17, notch 18, ring member with hole 19, steel ball 20, slot structure 21, right interface 22, right spool 23, spring c, right thimble 24.

[0024] Such as figure 1 ——As shown in 7, the left joint 1 is fixedly connected to the joint body 4, the left valve core assembly 3 is placed in the inner cavity formed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com