Clamping device

A clamping device and clamping tool technology, used in positioning devices, clamping, accessories of tool holders, etc., can solve problems such as imbalance, accumulation of debris in the shock-absorbing inner cavity, leakage, etc., to prevent leakage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

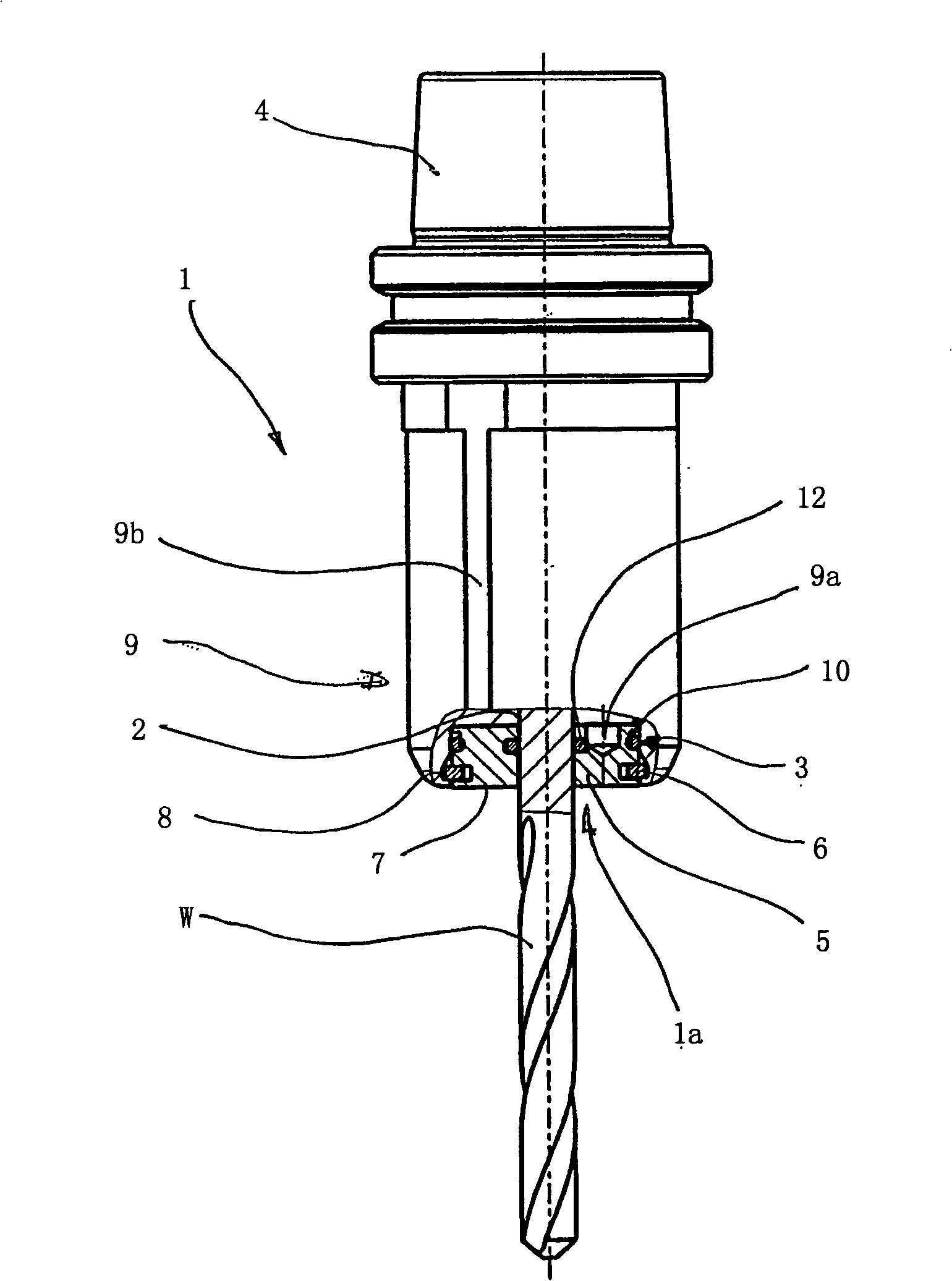

[0023] exist figure 1 The middle figure shows a specific embodiment of a clamping device according to the invention for clamping a tool, which is designed here as a clamping chuck, but can also be integrated, for example, directly into the work spindle of a machine tool. The clamping chuck comprises a base body 1 made of a dimensionally stable material, such as steel, which has a central receptacle 2 at its end for a tool W to be clamped, here a core drill, of Cylindrical handle. At its other end, the base body 1 has, in a known manner, an interface 4 for clamping into a working spindle of a machine tool.

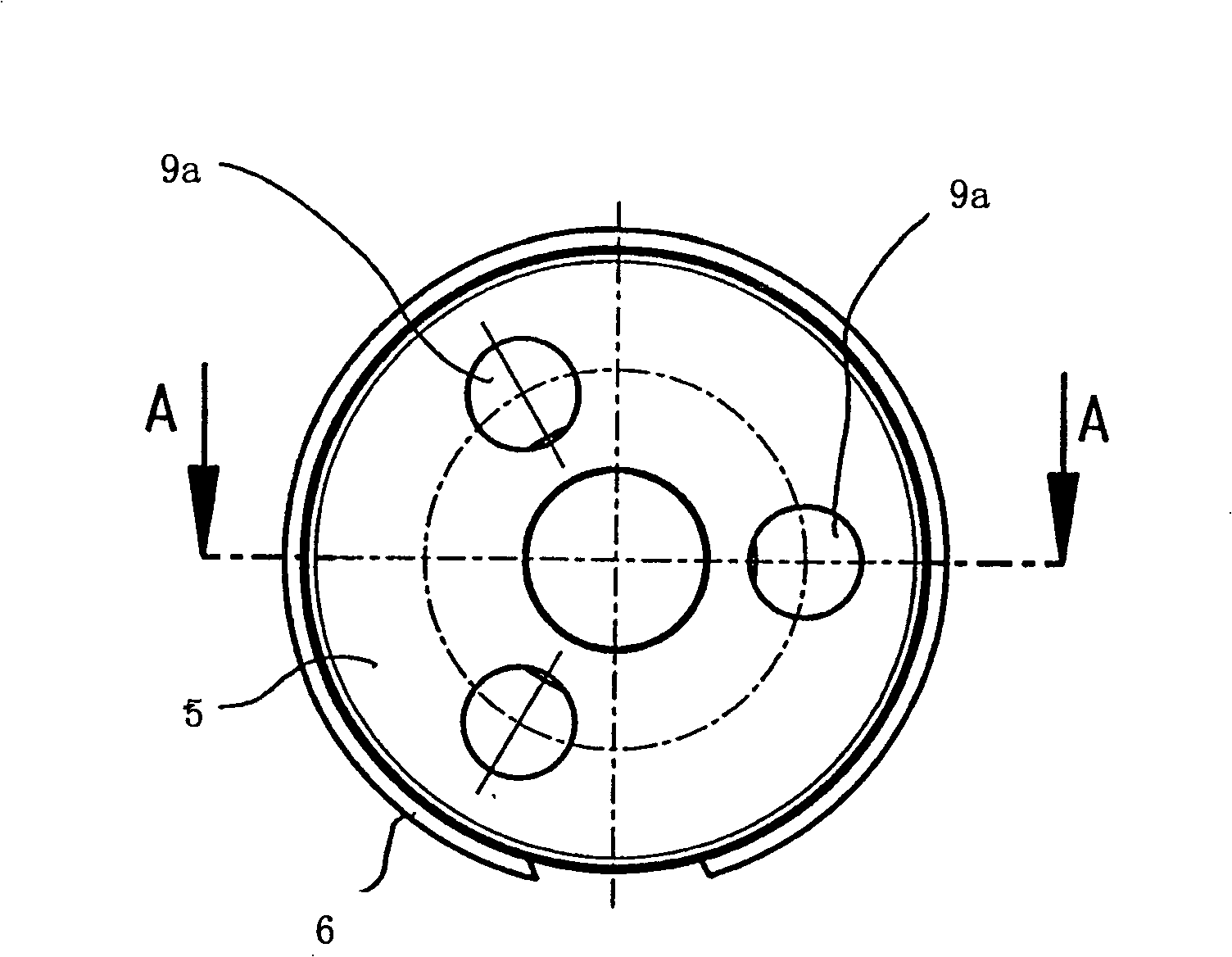

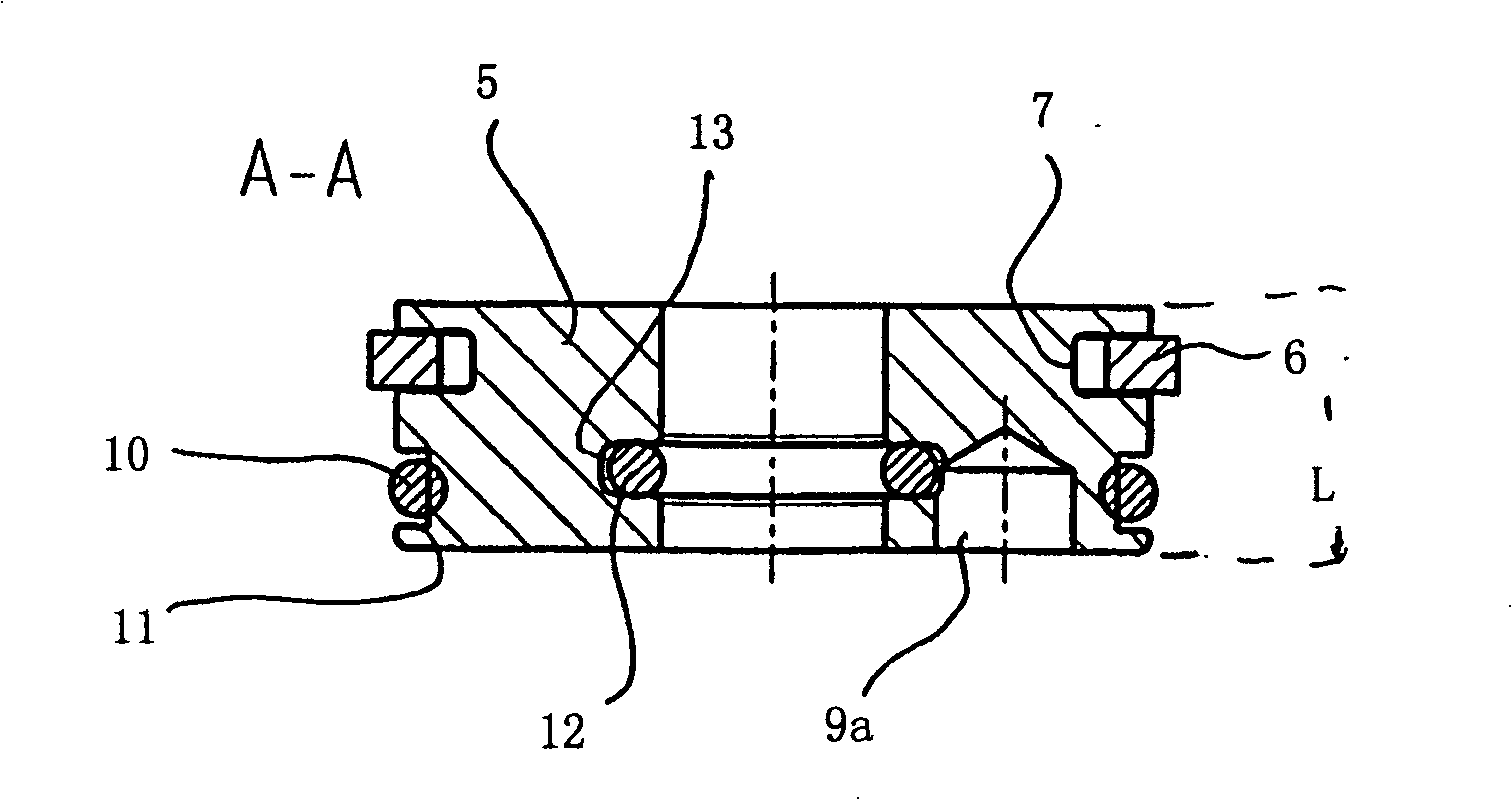

[0024] An annular space 3 is provided in the base body 1 , which surrounds the front region of the receptacle 2 and is open towards the tool-side end face 1 a of the base body and towards the receptacle 2 . The annular cover 5 is inserted into the annular space 3 and is secured axially by a locking ring 6 which engages in corresponding annular grooves 7 , 8 in the outer w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com