High-pressure grease injector

A high-pressure oil injection and oil injection technology is applied in the direction of pressure lubricants, lubricating oil control valves, engine components, etc. It can solve problems such as easy deformation, poor contact fit, and failure to achieve one-way check, so as to achieve a good check effect , Strong practicability, and the effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

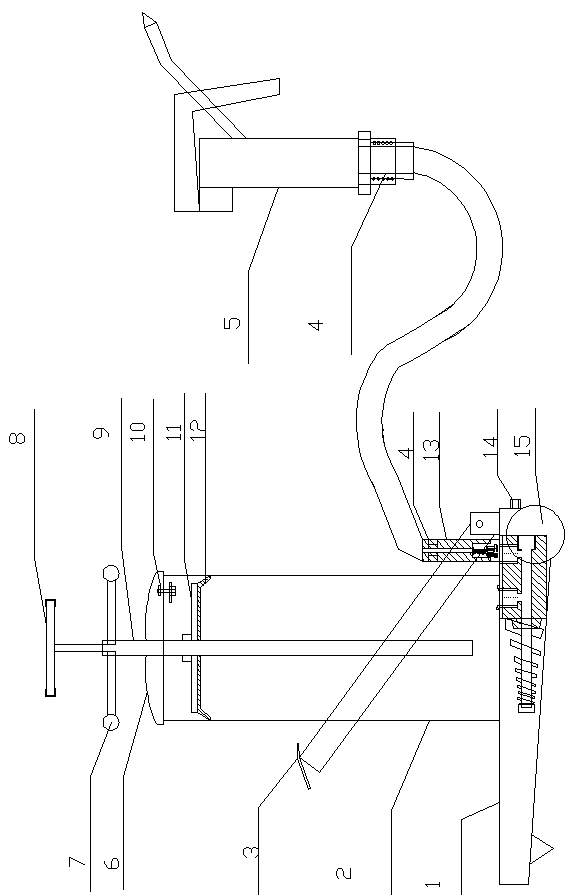

[0012] The present invention is further described in conjunction with the accompanying drawings and examples.

[0013] Such as figure 1 As shown, the high-pressure oiler includes a base 1, a barrel body 2, an oiler cover 6, a pedal bracket 3, an oil injection pump, a high-pressure hose 4, an oil injection gun 5, and an oil injection check valve 13.

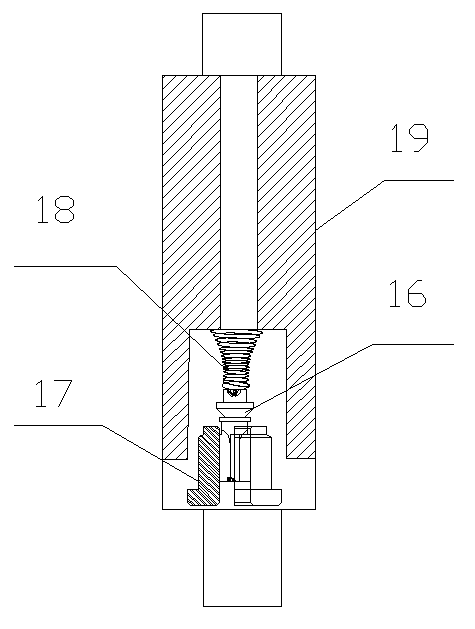

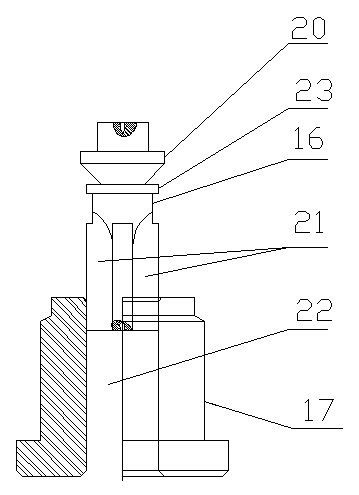

[0014] Oil injection pump comprises back-moving spring, piston, pump chamber, and pump chamber is provided with deflation nut 14, and the piston rod of piston connects pedal support 3. Ladle body 2 is provided with bung 6, and bung 6 is fixed on ladle body 2 by loam cake bolt 10. A screw mandrel 9 is provided in the middle hole of the bung 6 . The barrel body 2 and the oil filling pump are installed on the base 1, and the base 1 is provided with wheels 15.

[0015] The bottom of leather cup 12 is connected with bolt and is fixed on oil pressure plate 11 to form rubber bowl piston. Stretch into the screw mandrel 9 below the bun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com