Drainage balanced top-mounted built-in gas wave refrigerator

A gas wave refrigerator and built-in technology, which is applied in the field of pressure gas expansion refrigeration to achieve the effects of reducing labor intensity and workload, improving service life, and avoiding friction and ignition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

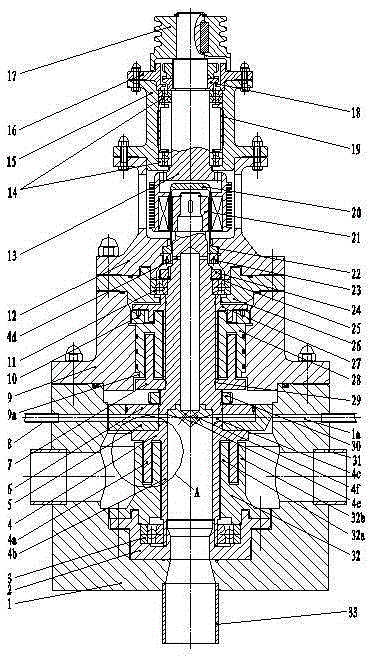

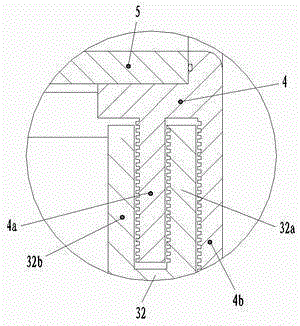

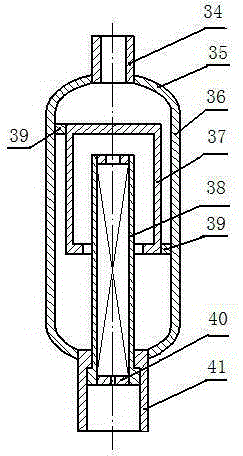

[0027]Figures 1 and 2 show the structural diagram of a top-mounted built-in air wave refrigerator with balanced drainage. In the figure, the drainage balanced top-mounted built-in gas wave refrigerator includes a body composed of a main body 1, an upper body 9, a coupling box 12 and a bearing box 15, and a main shaft for driving the rotating nozzle 5 to rotate is arranged in the body mechanism, spindle support and spindle seal. The body adopts the main body 1, the upper body 9, the upper bearing seat 26, the coupling box seat 12 and the bearing box seat 15 to be fixedly connected together in turn, and the main shaft mechanism adopts the external magnetic cylinder conjoined short shaft 13 provided with a pulley 17 through the magnetic The shaft coupling is connected to the main shaft 4, and the main shaft 4 is divided into the connection end with the air pressure balance hole and the air intake end with the air intake hole from the position where the rotating nozzle 5 is instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com