Gas meter flat wire sealing assembly

A technology of sealing components and flat wires, which is applied in the field of gas meter flat wire sealing components, which can solve the problems of easy aging of sealant, impact on production, loosening, etc., and achieve the effect of strong sealing reliability and time-saving and labor-saving assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

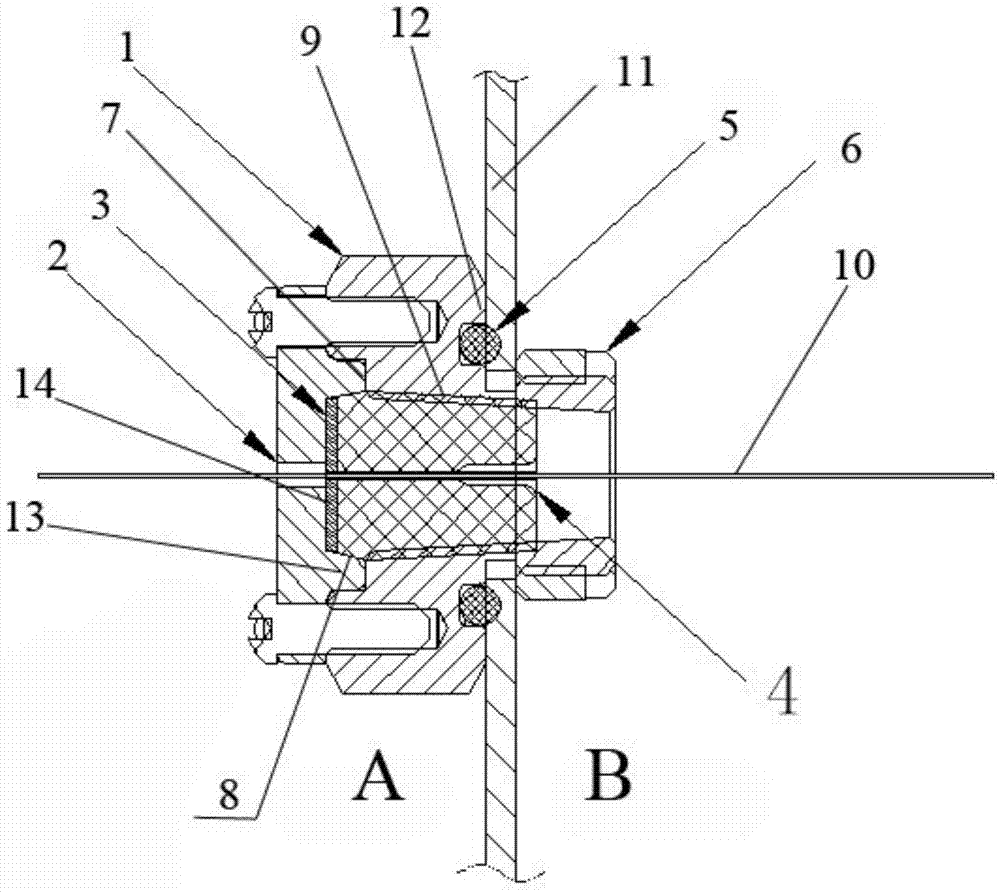

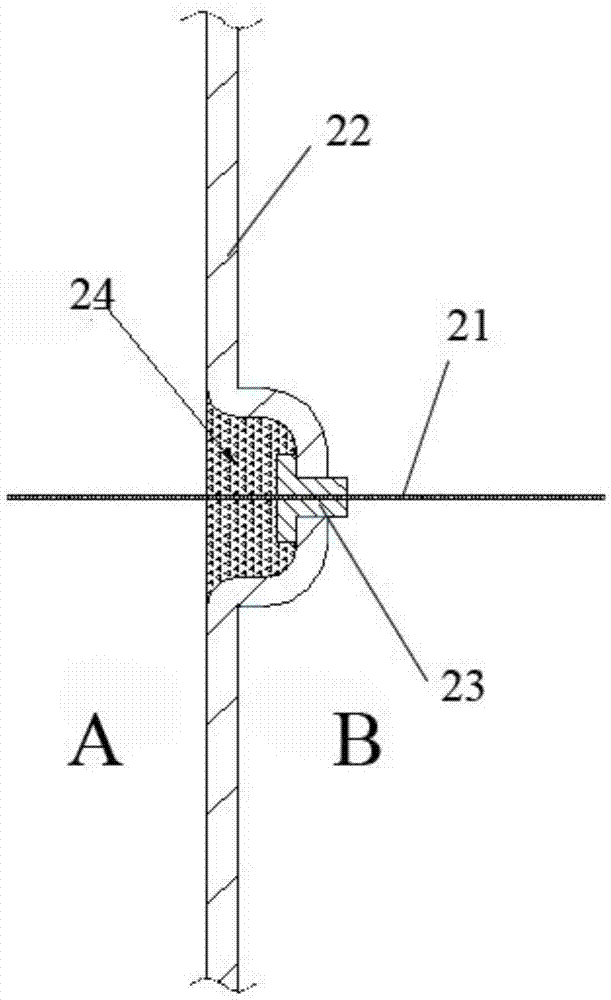

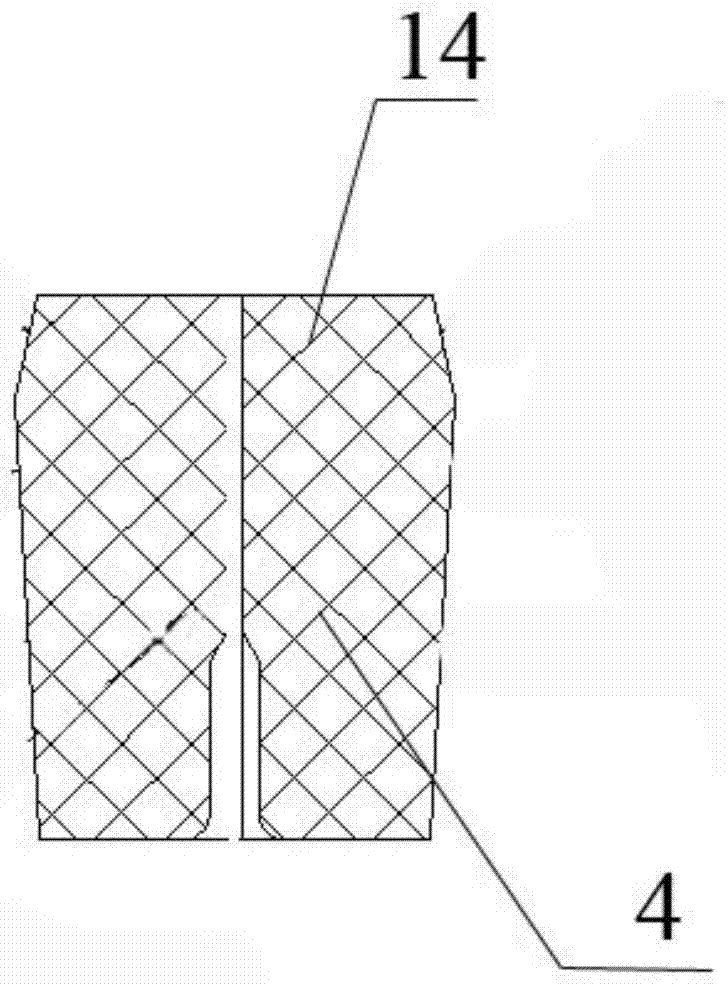

[0016] Such as figure 1 Shown: a gas meter flat wire sealing assembly, which has a flat wire 10 that runs through the inside and outside of the watch case 11; the plug in the through hole of the watch case 11 has a stopper 12 and an axial tapered hole 9, and two ends The adapter 1 located inside and outside the watch case 11, the upper end surface of the adapter 1 is provided with a stepped platform 7 matched with the axially perforated adapter cover 2, and the axial taper hole 9 of the adapter 1 is inserted into the There is a conical rubber plug 4 with axial perforation, the top of the conical rubber plug 4 is provided with a conical platform 14 with an angle of 10°, and the adapter cover 2 is provided with an assembly boss that matches the stepped platform 7 13. The assembly boss 13 is provided with an assembly groove 8 matching the tapered table 14, and the top of the outer end surface of the tapered rubber plug 4 is provided with an axially perforated gasket 3; The conn...

Embodiment 2

[0024] This embodiment is basically the same as that of Embodiment 1, except that the top end of the tapered rubber plug 4 is provided with a conical platform 14 with an angle of 15° to cooperate with an assembly boss 13 with an angle of 12°, so that it can be more Effectively compress the tapered rubber plug 4 in the axial tapered hole 9, so that the sealing effect is good.

[0025] The gas meter flat wire sealing assembly of the present invention saves time and effort in assembly, has strong sealing reliability, reduces the overall area by using flat wires, and has a long service life

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com