Semi-automatic platform for conical-surface mirror detection

A semi-automatic, conical technology, applied in the direction of testing optical performance, etc., can solve the problems of conical mirror tilt and slow speed, and achieve the effect of smooth operation, high precision and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

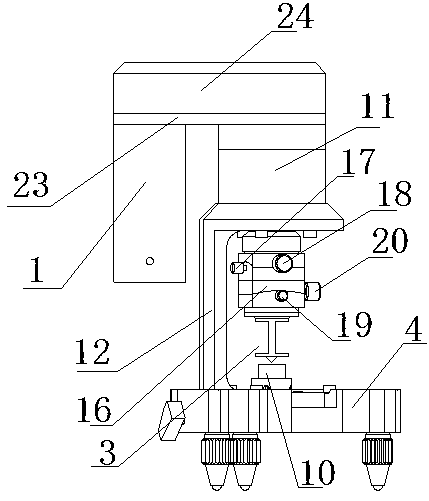

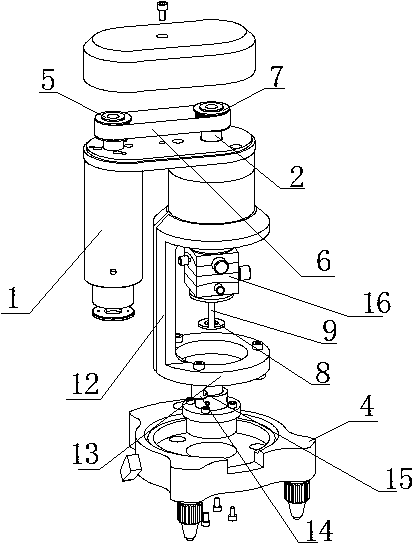

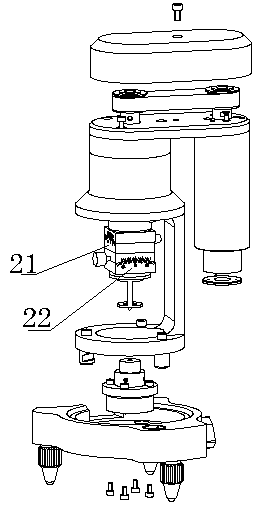

[0012] In order to enable the linear CCD probe to detect the 360° laser line formed by the spot laser hitting the conical mirror, this embodiment provides a figure 1 , 2 The semi-automatic conical mirror detection platform shown in 3 includes a rotating motor 1, a rotating shaft 2, a conical mirror base 3, and a laser level adjustment seat 4; the rotating motor 1 passes through the motor gear 5 and the transmission belt 6 on its transmission shaft , The shaft gear 7 at the top of the rotating shaft 2 drives the rotating shaft 2 to rotate; the conical mirror lens holder 3 is arranged at the bottom end of the rotating shaft 2, and the conical mirror lens holder 3 includes a ring 8 and symmetrically arranged vertically at The two connecting rods 9 on the top edge of the ring 8 are connected to the bottom surface of the rotating shaft 2, and the inner edge of the ring 8 extends inward to form a shape that coincides with the bottom edge of the conical mirror The ring frame; the axis ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com