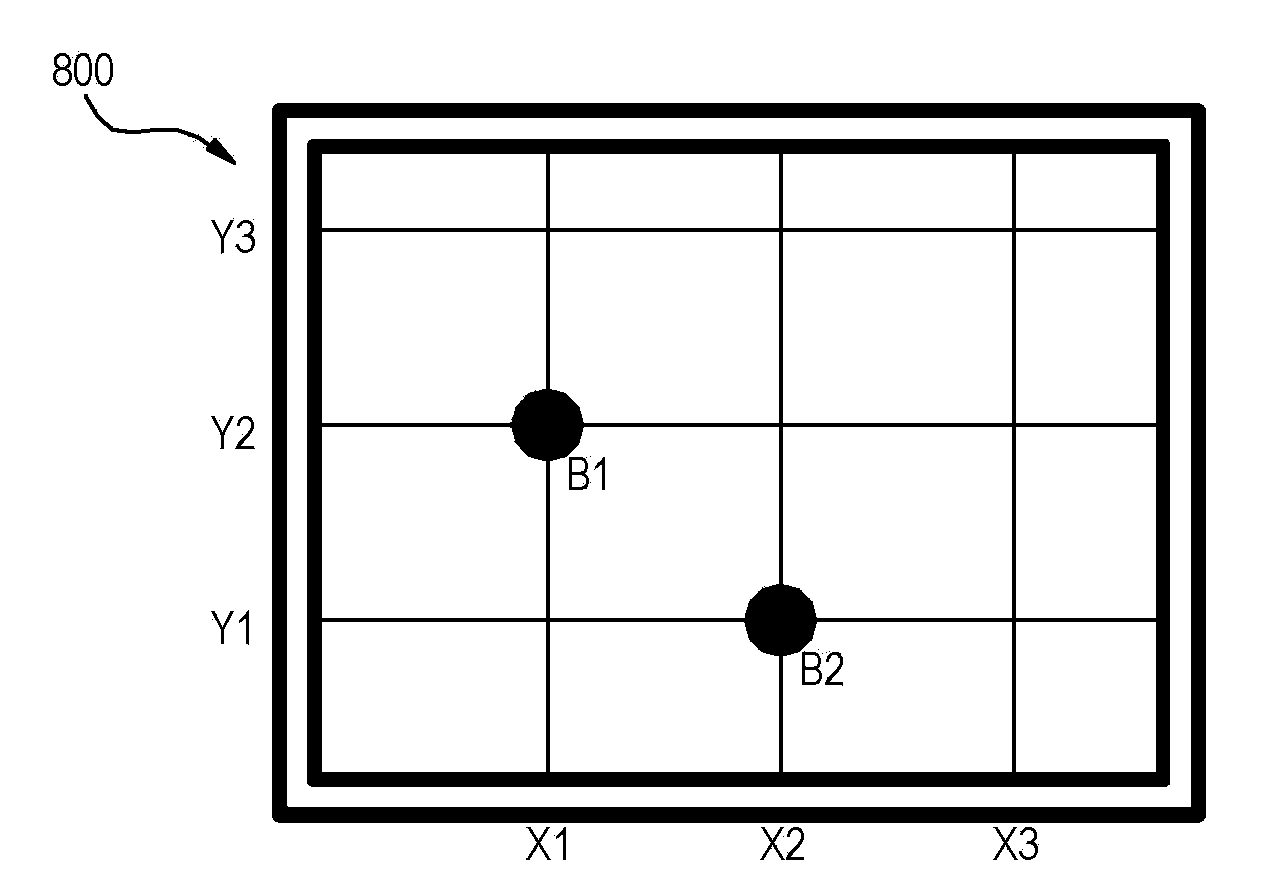

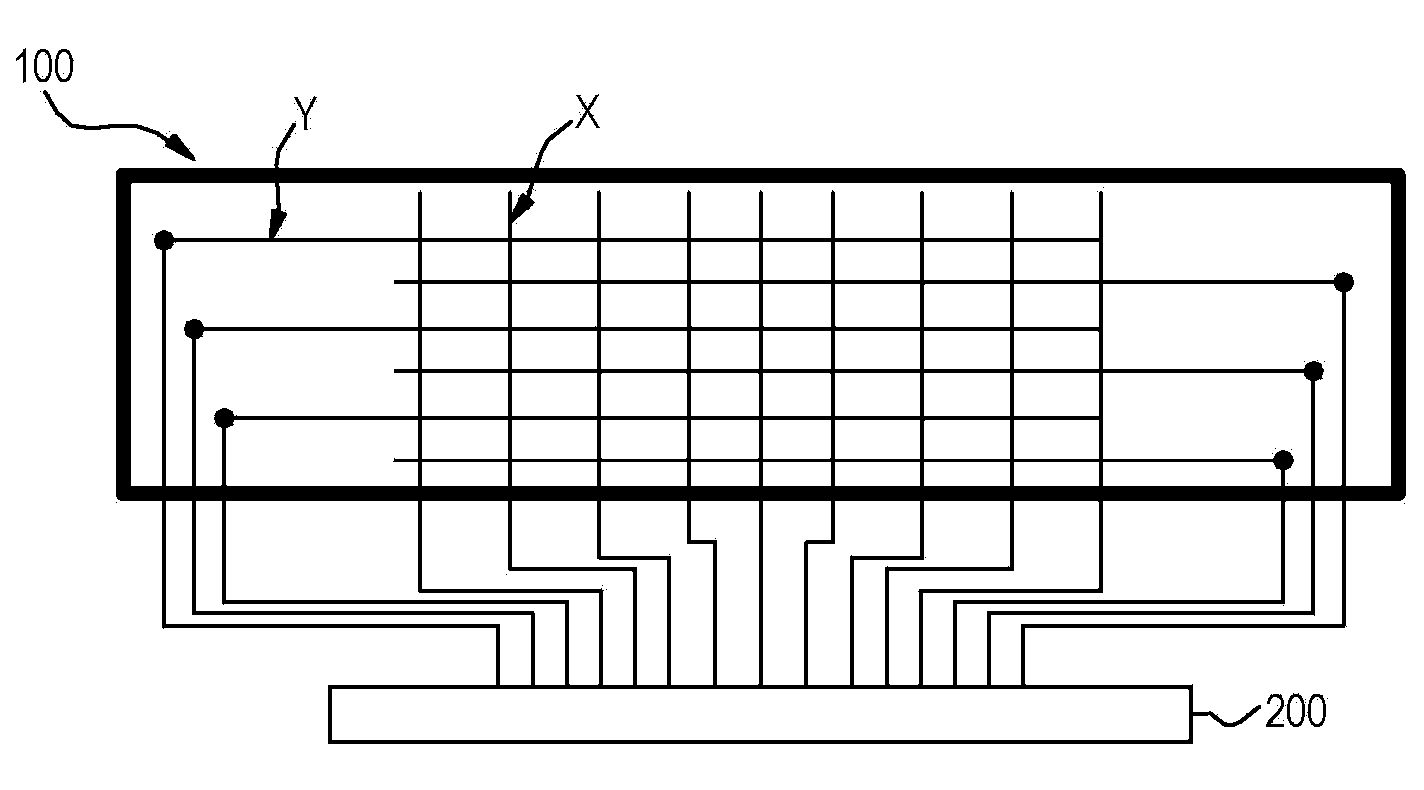

Method and device for determining positions of multi-touch of touch panel

A multi-touch and touch panel technology, applied in the input/output process of data processing, instruments, electrical digital data processing, etc., can solve signal drift, high environmental sensitivity, time-consuming capacitive touch panel, etc. problem, to achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0073] In the first case, please also refer to Figure 5 . Assume: the elasticity parameter is 0.5, the capacitance signal of the touch point P1 is 140, the capacitance signal of the touch point P2 is 20, the capacitance signal of the touch point P3 is 30, and the capacitance signal of the touch point P4 is 150.

[0074] The maximum capacitance signal obtained from step S206 is 150; the minimum capacitance signal is 20.

[0075] From step S208, the maximum capacitance signal, the minimum capacitance signal and the elasticity parameter are substituted into the formula: threshold value = maximum capacitance signal × elasticity parameter + minimum capacitance signal × (1 - elasticity parameter);

[0076] Threshold value = 150× 0.5 + 20× (1 – 0.5);

[0077] Threshold = 85.

[0078] From step S210, compare the capacitance signals of the touch points P1, P2, P3 and P4 with the threshold value: the touch points P1 and P4 are greater than the threshold value to be a real touch poin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com