Circuit board and manufacturing method thereof

A technology of circuit boards and graphics, which is applied in the fields of printed circuit manufacturing, printed circuits, printed circuit components, etc., can solve the problems of leakage, increased risk of abnormal boards, and low production efficiency, so as to prevent missed inspections, reduce manpower consumption, The effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The circuit board provided by the technical solution and its manufacturing method will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0016] The manufacturing method of the circuit board provided by the embodiment of the technical solution includes the following steps:

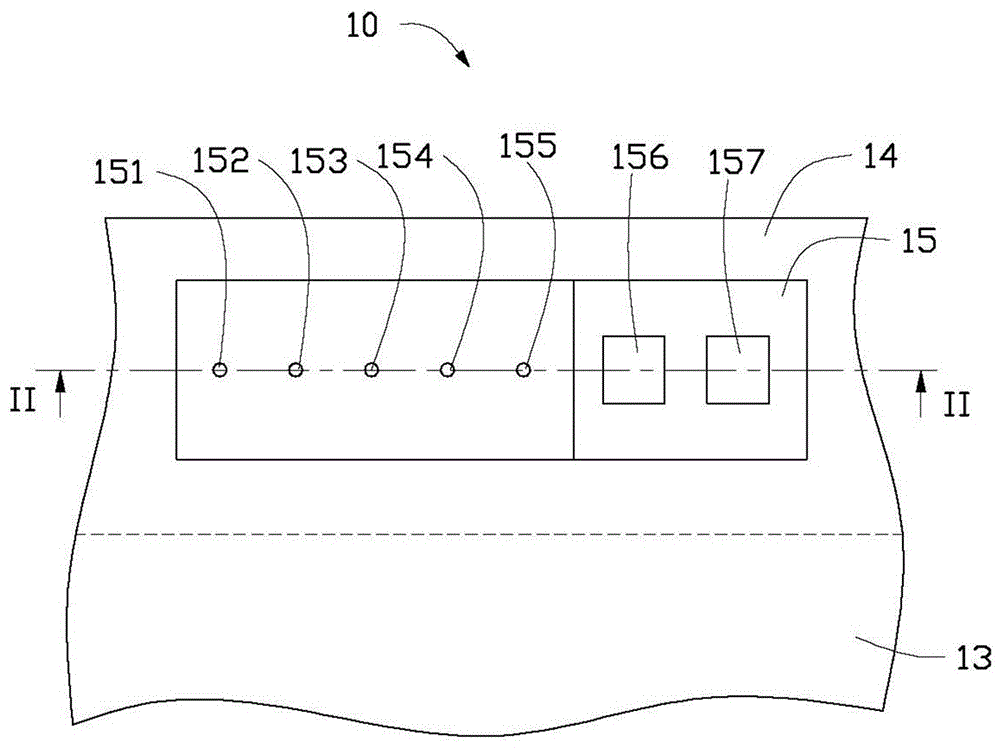

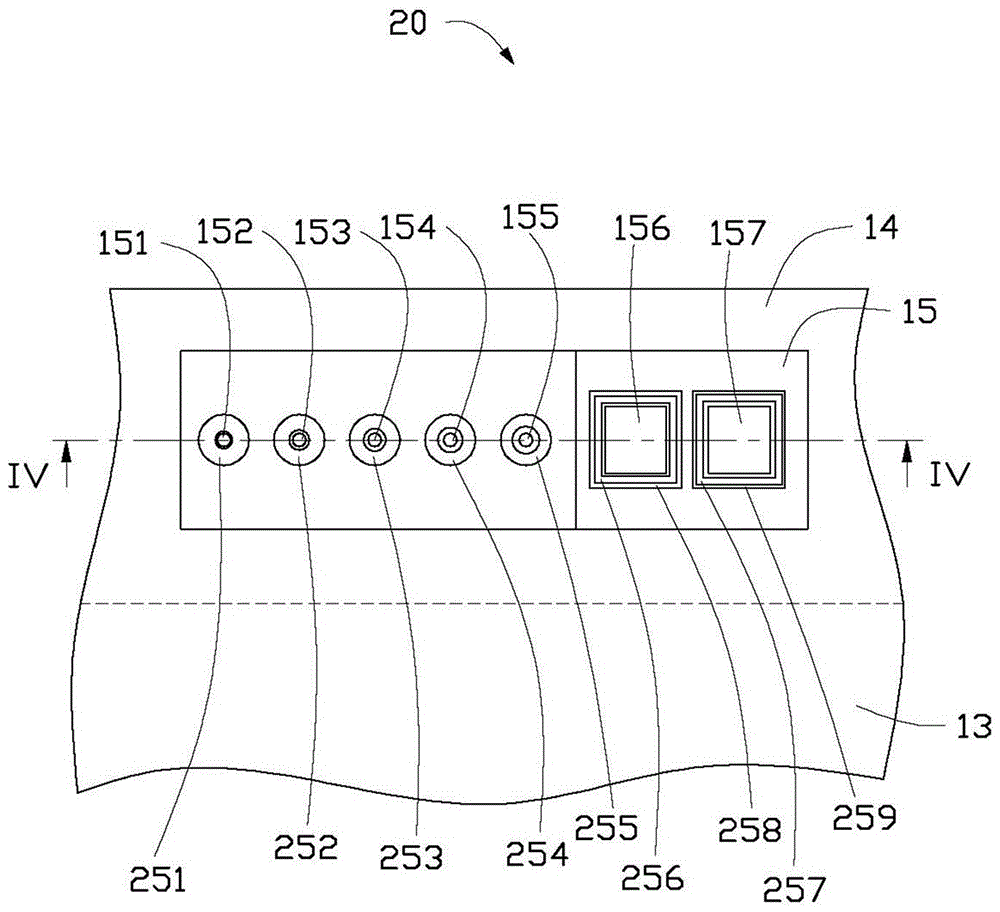

[0017] For a first step, see Figure 1-2 , a circuit substrate 10 is provided.

[0018] In this embodiment, a single-sided circuit substrate 10 is taken as an example for illustration. The circuit substrate 10 includes a conductive circuit layer 11 and an insulating layer 12 .

[0019] The conductive circuit layer 11 and the insulating layer 12 are made of commonly used materials for circuit boards. For example, the material of the conductive circuit layer 11 can be copper, silver, tin, etc.; the material of the insulating layer 12 can be pure resin such as epoxy resin, polyimide resin, etc., or a resin containing reinforcing materials. Such as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com