Printed circuits for securing the connection of electric motors and electric motors including printed circuits

A technology for printed circuits and motors, applied in the directions of printed circuits, printed circuits, printed circuit components, etc., can solve the problems of increasing the weight, volume and cost of the motor environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Most rotating electric machines have overall an outer surface in the form of a cylindrical section bounded by two planes. The axis of rotation of the motor is the shaft of the cylinder and the motor wiring is made on one of the two planes by tongues to which the power cord can be connected, for example by welding or via a connector. Hereinafter, the term "motor power cord" shall include any connection means for a motor to ensure its power supply, such as a flexible printed circuit. One of the two planes and the cylindrical portion may be formed by a metal casing. The second plane may be made of plastic material through which the motor wiring is left.

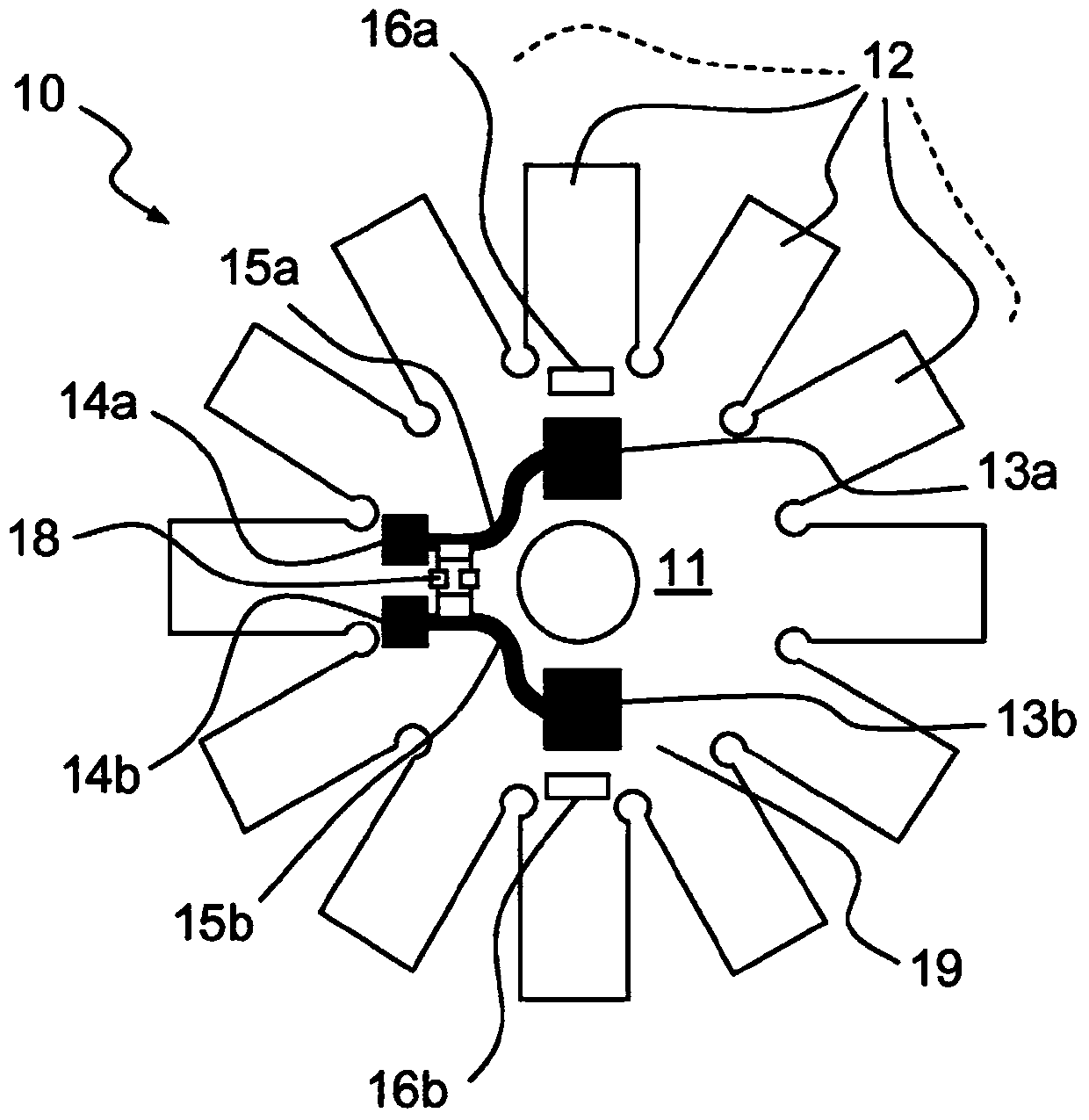

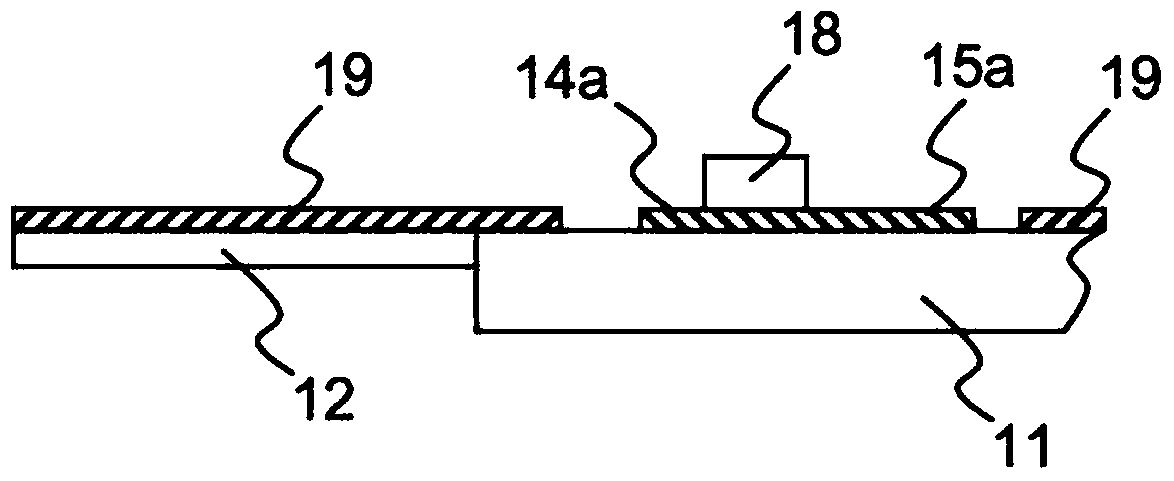

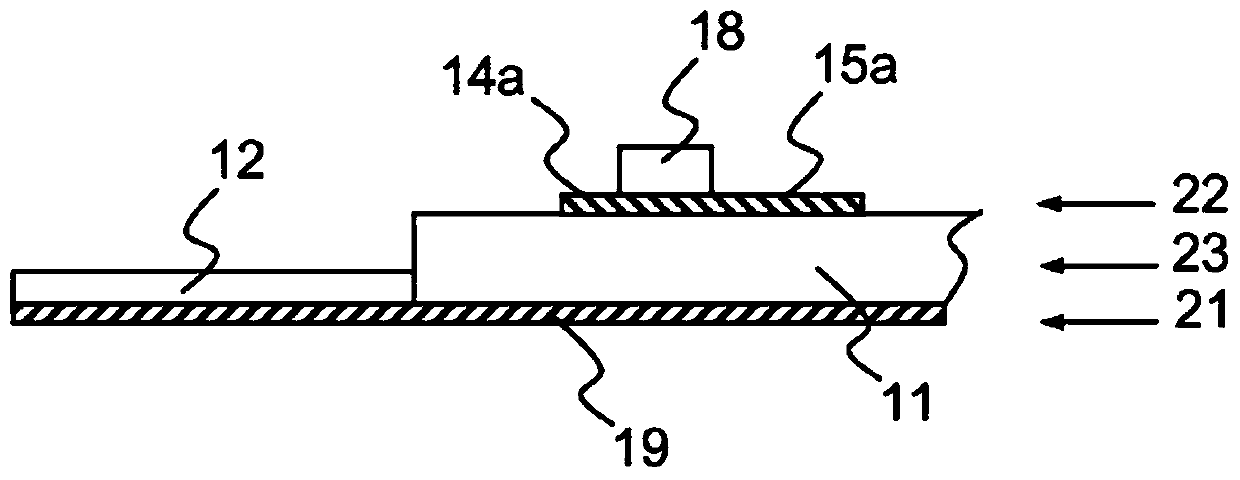

[0028] figure 1 A single sided printed circuit 10 is shown for fixing to the motor to ensure its electrical connection. It is contemplated that a single-sided printed circuit be formed from an insulating substrate with one side receiving conductive traces. Thus, realization of a single-sided printed circuit enables re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com