Friction clutch device

A technology of friction clutches and components, applied in the direction of friction clutches, clutches, mechanically driven clutches, etc., which can solve the problems that the disc spring cannot be erected significantly and the stroke is short

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

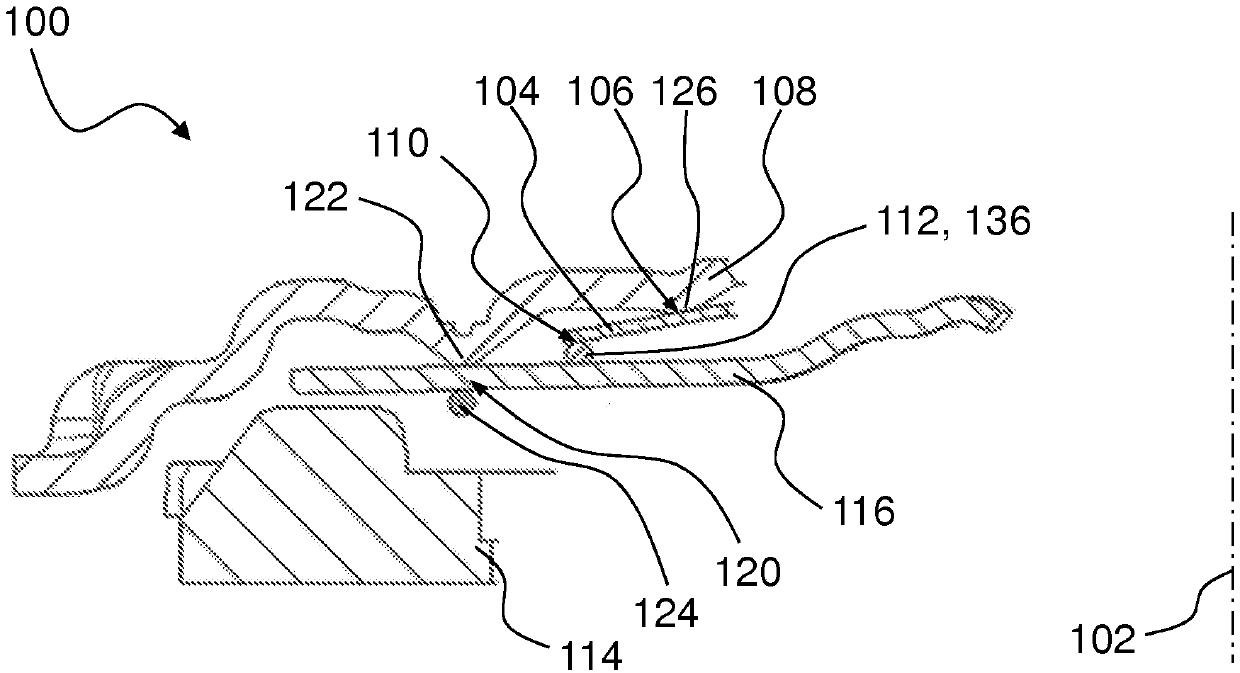

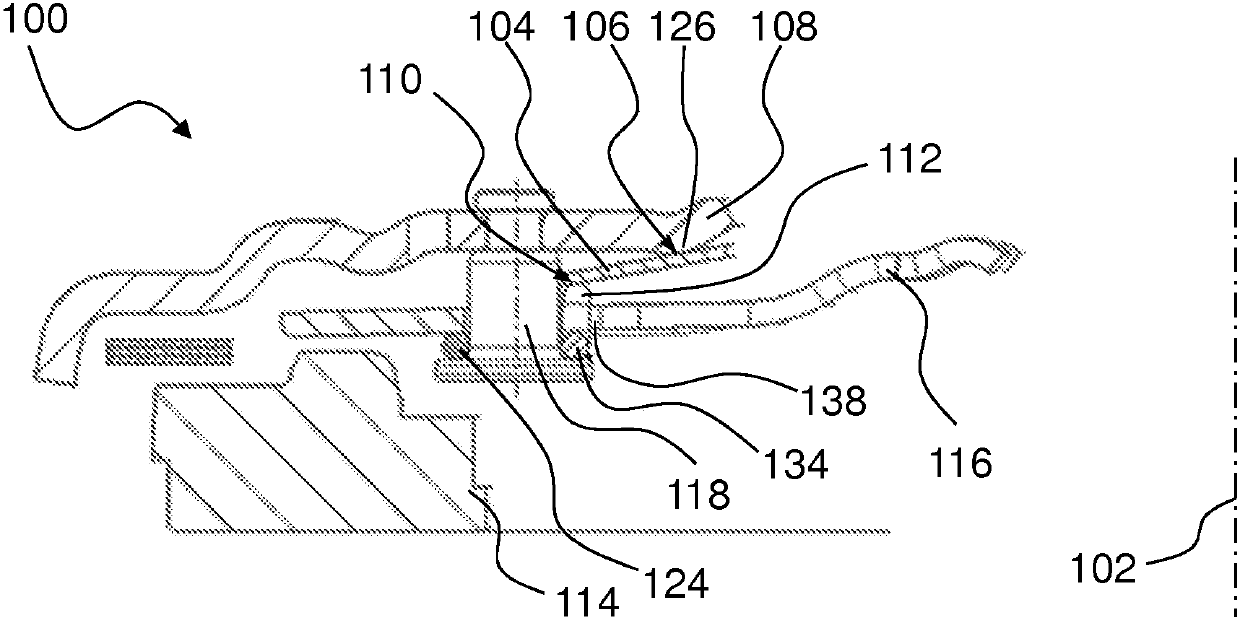

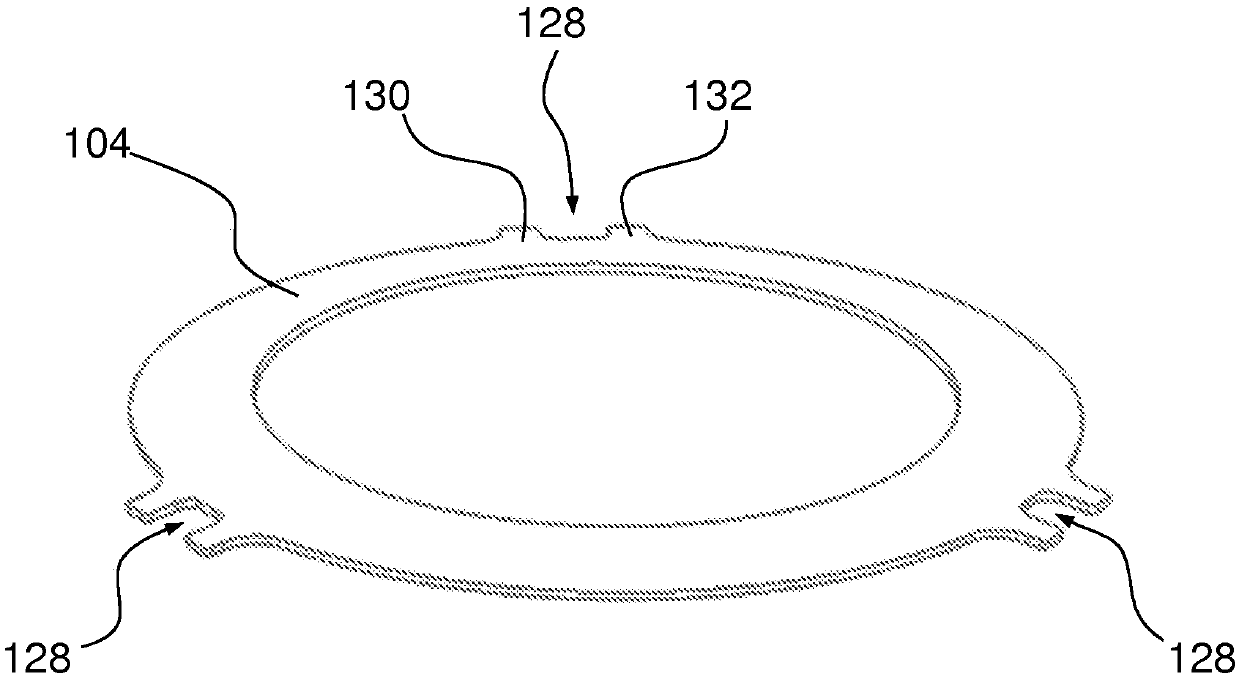

[0036] figure 1 and figure 2 Partially shows a clutch 100 rotatable about an axis of rotation 102 , which has a servo spring 104 which is supported on a housing 108 with a first support radius 106 and is supported with a second support radius 110 in a configuration configured as On the support ring of the first wire ring 112. The directional designations used below, axial, radial, circumferential and circumferential directions are all relative to the axis of rotation 102 .

[0037] Clutch 100 is a friction clutch. Clutch 100 is a single disc dry clutch. The clutch 100 can be arranged between the internal combustion engine and the transmission in the drive train of the motor vehicle. A torsional vibration damper, in particular a dual mass flywheel, can be arranged between the internal combustion engine and the clutch 100 . Clutch 100 has an input portion and an output portion. The input part comprises: a housing 108 , a pressing plate fixedly connected to the housing 108...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com