Medium-speed vertical mill for milling petroleum coke

A technology of petroleum coke and grinding device, applied in grain processing and other directions, can solve the problems of no dynamic and static combined rotary separator, unable to achieve stable and balanced classification flow field, etc., to improve grinding efficiency, optimize grinding curve, and improve service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0074] In order to better understand the present invention, the present invention is described in detail below in conjunction with specific embodiment, but obviously can carry out different modification and modification to the present invention and not exceed the broader spirit and scope of the present invention that appended claims limit . Accordingly, the following examples are illustrative and not limiting.

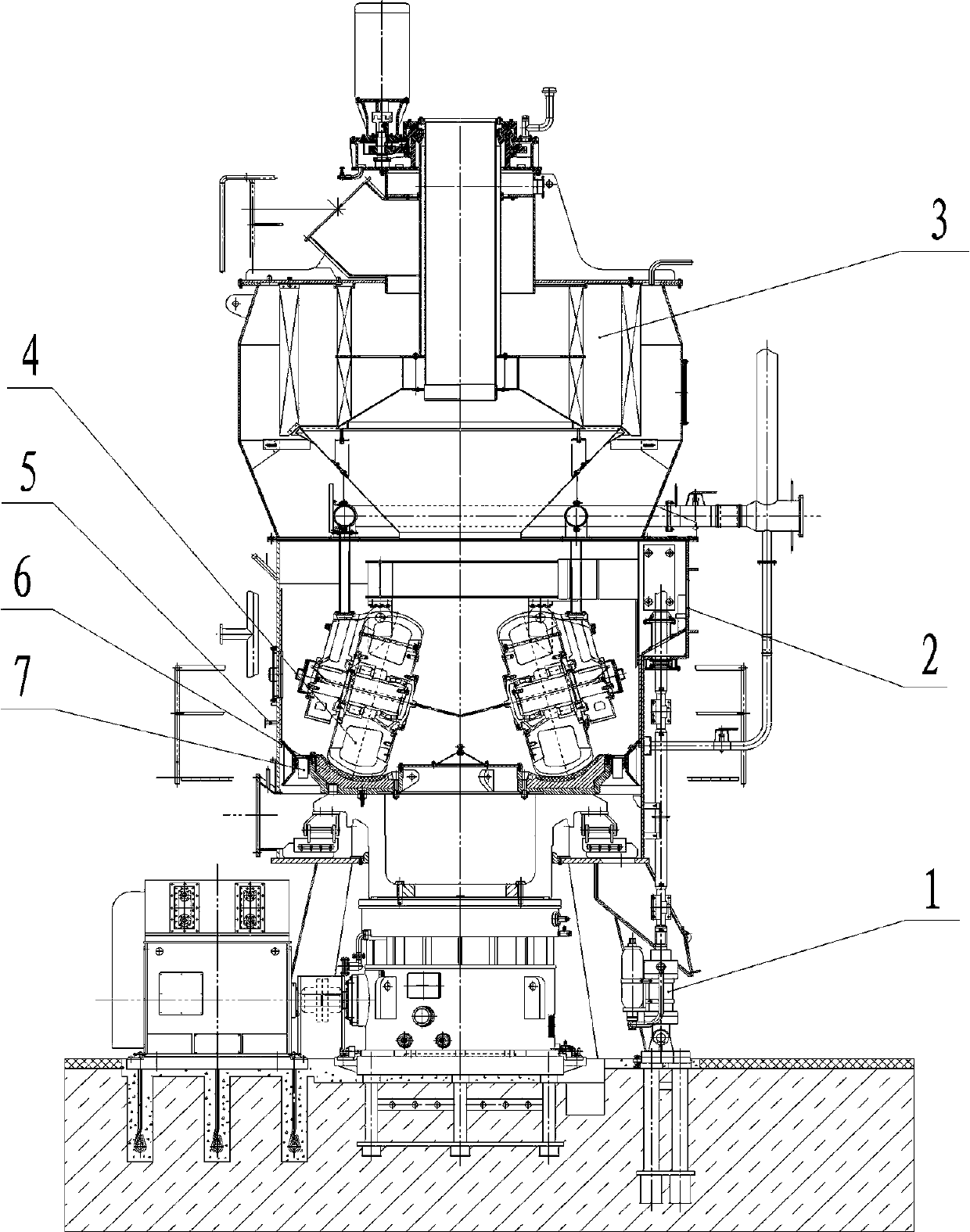

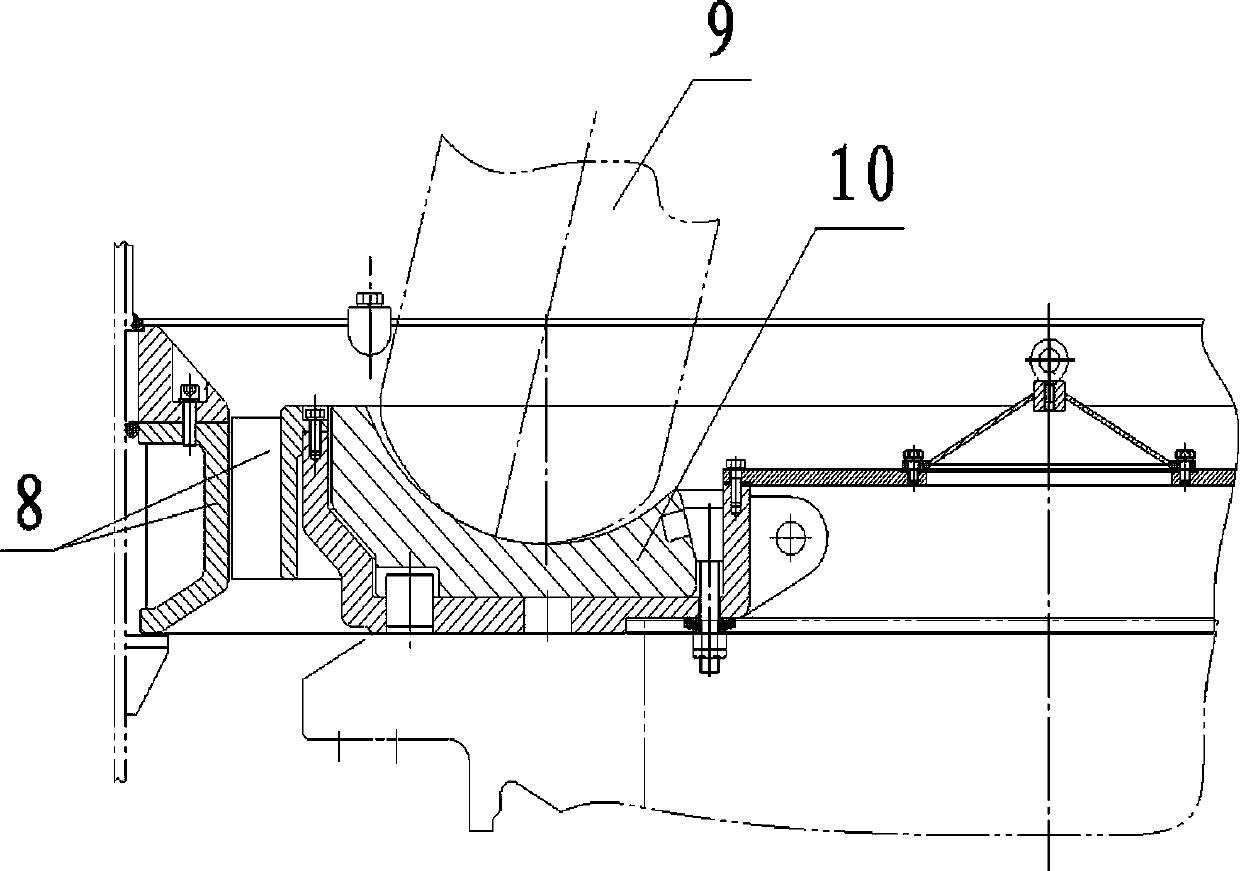

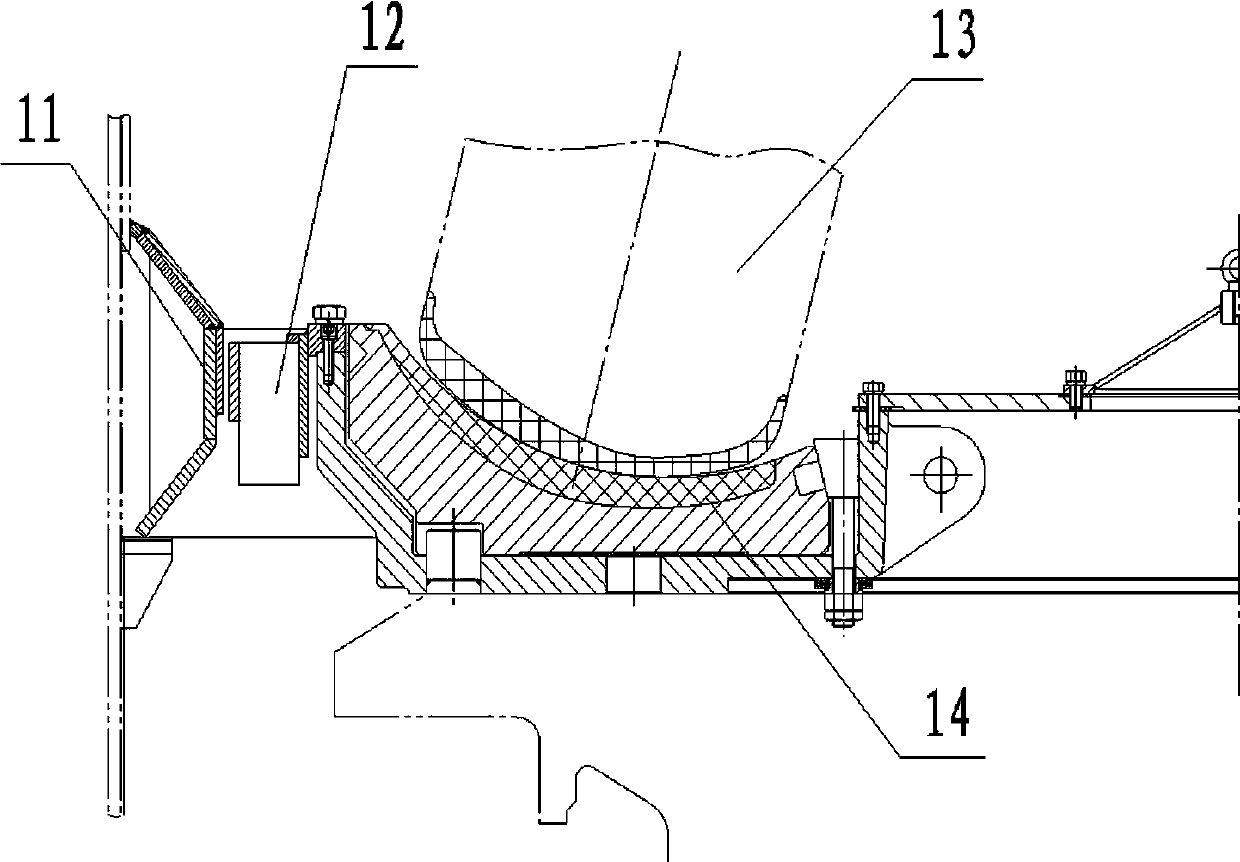

[0075] Such as Figure 1-15 As shown, a medium-speed vertical mill applied to grinding petroleum coke includes a grinding device, the grinding device includes a grinding roller assembly 4 and a grinding disc assembly 6, and the grinding roller assembly 4 includes a grinding roller and a grinding roller sleeve, so The grinding disc assembly 6 is provided with a lining plate, wherein: the width of the grinding roller sleeve is increased by at least 10mm on the original basis, the thickness of the lining plate is increased by at least 20mm, and the wrap angle of the grin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com