Plate machining method using left-and-right moving lead screw and being capable of pressing lines

A technology of moving left and right and sheet metal processing, which is applied in the field of sheet metal processing, can solve the problems that it is difficult to guarantee the shape of the sheet metal processing, the final quality of the sheet material is greatly affected, and it is difficult to ensure the surface processing accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

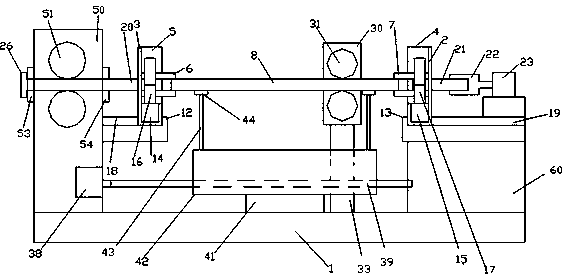

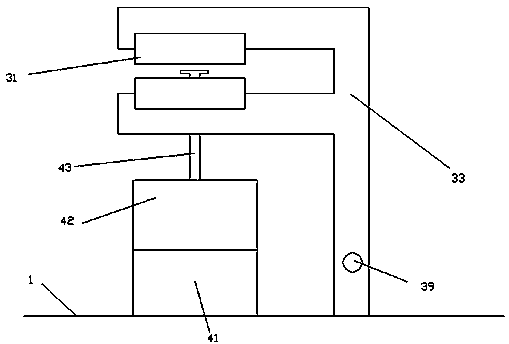

[0022] Attached below Figure 1-2 The present invention will be described in detail.

[0023] A sheet material processing method that uses a left and right moving screw and can suppress lines, it uses a sheet material processing device, the sheet material processing device includes a bottom frame 1, a left frame 50 and a right frame 60, wherein the left frame 50 It is arranged on the left end of the underframe 1, and the right frame 60 is arranged on the right end of the underframe 1, and a plate conveying device and a rolling device 30 are arranged between the left end and the right end of the underframe 1, wherein the plate conveying device can make the loaded The sheet material moves along the front-to-back direction on the chassis 1, and the rolling device 30 can slide along the left-right direction on the bottom frame 1, and the front-to-back direction is a direction perpendicular to the left-right direction in the horizontal plane; the sheet material conveying device inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com