Hanger for mounting universal shaft of vertical mill and application method of hanger

A vertical rolling mill and cardan shaft technology, applied in the field of spreaders, can solve problems such as the difficulty in hoisting the cardan shaft, the inconvenient installation method of the cardan shaft of the vertical rolling mill, and the lack of corresponding guarantee for safety during installation, etc., to achieve Reduce engineering construction costs, improve construction efficiency, and achieve quick and convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Spreader for mounting cardan shafts of vertical rolling mills

[0031] The spreader for installing the cardan shaft of a vertical rolling mill according to the present invention comprises a steel frame 1, a closed support and a counterweight 5.

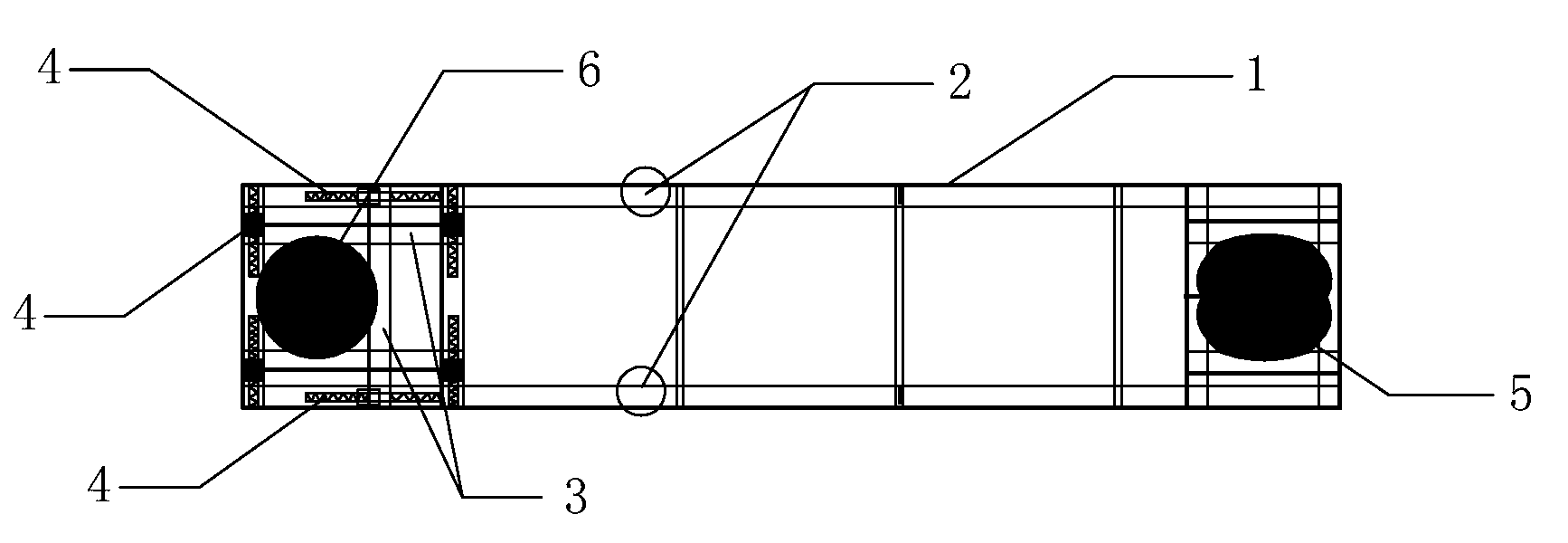

[0032] see now figure 1 , figure 1 It is a structural schematic diagram of the hanger implemented by the present invention. As shown in the figure, the steel frame 1 is a rectangular frame 3x0.6m reinforced and welded with angle steel ∠63*5 around it and some middle round steel Ф20mm, and a pair of lifting lugs 2 are arranged on both sides of the middle of the rectangular frame;

[0033] The closed bracket is fixed at one end of the steel frame 1, which is a square frame composed of angle steel 3 around and Ф24mm full-wire adjusting bolts 4 fixed with double nuts, and can be adjusted by adjusting the movable angle steel on the adjacent two sides and adjusting Bolts adjust the size of the square frame to suit the installation...

Embodiment 2

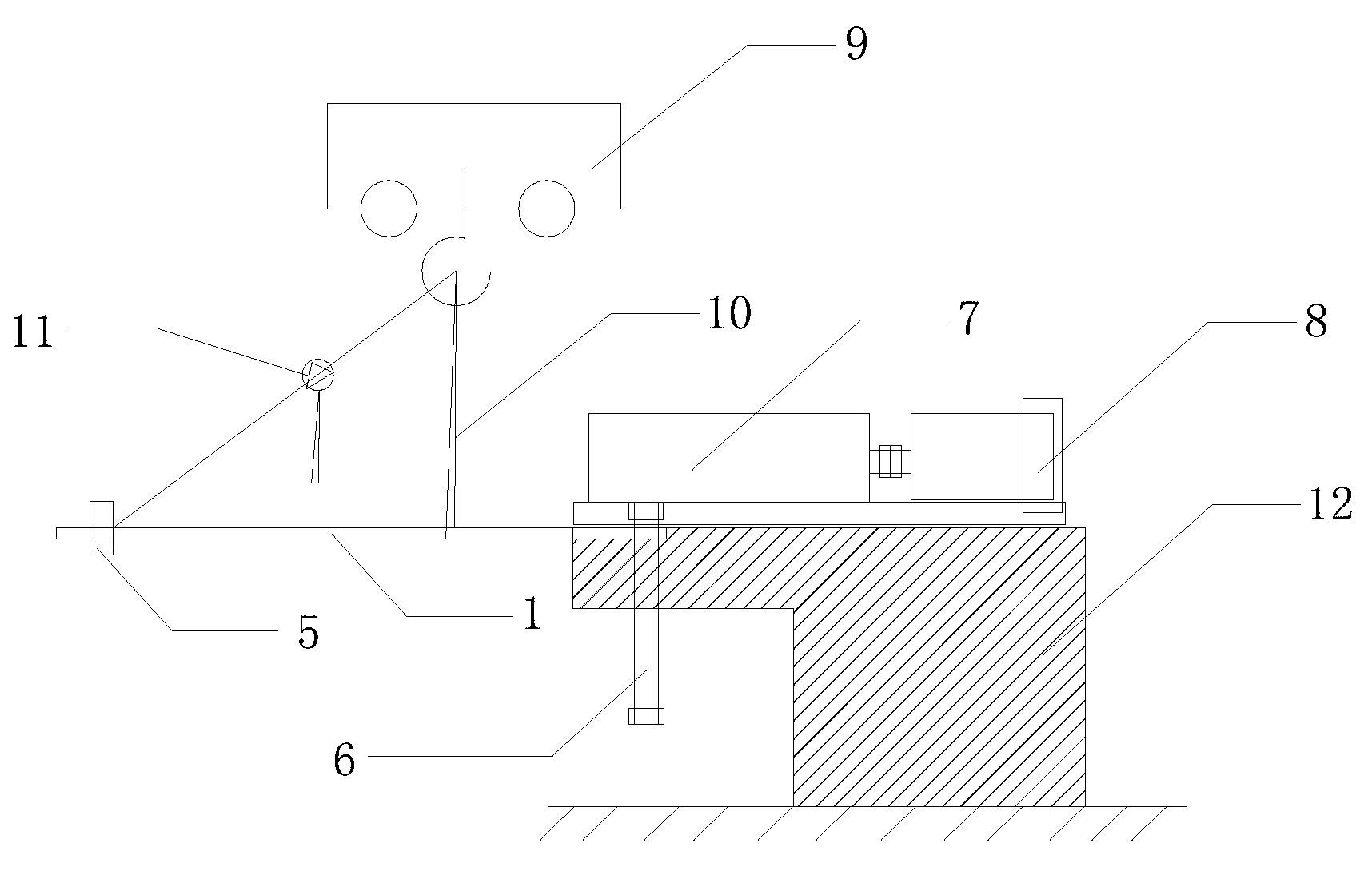

[0037] How to use the spreader for installing the cardan shaft of the vertical rolling mill

[0038] figure 2 It is a schematic diagram of the use state of the spreader implemented by the present invention. In the installation of cardan shafts of 9 vertical rolling mills in Jiujiang 1 million ton bar project, the weight of the cardan shafts is between 0.8t and 1.3t, calculated according to the heaviest cardan shaft of 1.3t, using the lever to balance the resistance *Resistance arm=power*power arm (1.3t*1m=0.65t*2m), that is, the counterweight is greater than or equal to 0.65t, and the counterweight of this project is about 0.8t, and the balance of the bracket is adjusted by a chain hoist, which can meet the 0.8 Cardan shaft installation between t-1.3t.

[0039] The method for using the spreader for installing the cardan shaft of a vertical rolling mill according to the present invention is characterized in that it comprises the following steps:

[0040] a. Provide a crane,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com