A kind of non-phosphorus copolymer antiscaling dispersant and preparation method thereof

A technology of scale inhibitor and dispersant and copolymer, which is applied in the field of circulating cooling water treatment, can solve the problems of increasing the difficulty of sterilization and algae killing of circulating water system, affecting the stable operation of circulating water system, and increasing the complexity of circulating water treatment, etc., to achieve Good scale inhibition and dispersion effect, high economic and social benefits, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

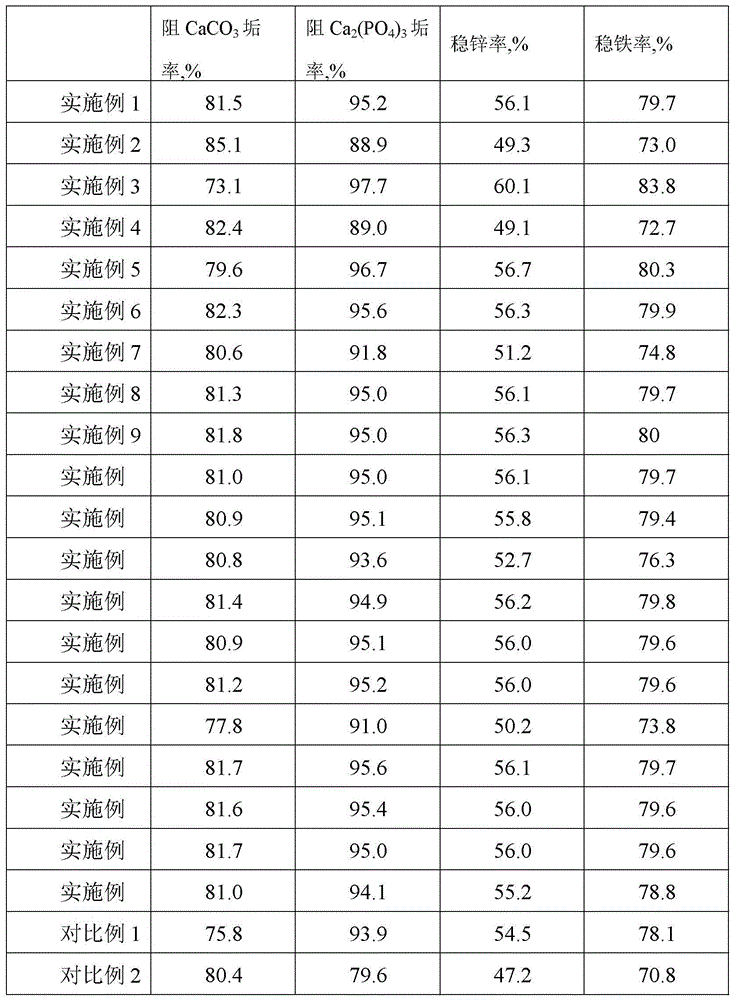

[0063] Take by weighing 70g of itaconic acid, 11g of sodium pyrosulfinate, measure 90ml of water, stir to make it dissolve, add in the four-neck flask equipped with agitator, reflux condenser, constant pressure dropping funnel and thermometer; Dissolve 11g of ammonium sulfate in 40ml of water and add to constant pressure funnel Ⅰ; weigh 15g of allylsulfonic acid and 15g of methyl acrylate, dissolve in 70ml of water, mix well, add to constant pressure funnel Ⅱ; At 80°C, add ammonium persulfate solution, allyl sulfonic acid, and methyl acrylate mixed solution dropwise; control the dropwise addition for 2 hours; after the dropwise addition, keep warm at 90°C for 3 hours; cool to obtain the product. The solid content of the obtained copolymer antiscalant dispersant was 37.9%, the molecular weight was 5000, and the antiscalant performance of the product was shown in Table 2.

Embodiment 2

[0065] Take by weighing 80g of itaconic acid, 11g of sodium pyrosulfinate, measure 90ml of water, stir to make it dissolve, add in the four-neck flask equipped with agitator, reflux condenser, constant pressure dropping funnel and thermometer; Dissolve 11g of ammonium sulfate in 40ml of water and add to constant pressure funnel Ⅰ; weigh 10g of allyl sulfonic acid and 10g of ethyl acrylate, dissolve in 60ml of water, mix well, add to constant pressure funnel Ⅱ; At 80°C, add ammonium persulfate solution, allyl sulfonic acid, and ethyl acrylate mixed solution dropwise; control the dropwise addition for 2 hours; after the dropwise addition, keep warm at 90°C for 3 hours; cool to obtain the product. The solid content of the obtained copolymer antiscalant dispersant was 39.1%, and the molecular weight was 5250. The antiscalant performance of the product is shown in Table 2.

Embodiment 3

[0067] Take by weighing 60g of maleic acid, 11g of sodium pyrosulfinate, measure 90ml of water, stir to make it dissolve, add in the four-neck flask equipped with stirrer, reflux condenser, constant pressure dropping funnel and thermometer; Dissolve 11g of ammonium sulfate in 40ml of water and add to constant pressure funnel Ⅰ; weigh 20g of allylsulfonic acid and 20g of 2-methyl methacrylate, dissolve in 80ml of water, mix well, add to constant pressure funnel Ⅱ; heat up, When the temperature rises to 80°C, add ammonium persulfate solution, allylsulfonic acid, and 2-methyl methacrylate mixture dropwise; control the dropwise addition for 2 hours; after the dropwise addition, keep warm at 90°C for 3 hours; cool to obtain the product. The solid content of the obtained copolymer antiscalant dispersant is 36.7%, the molecular weight is 4700, and the antiscalant performance of the product is shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com