Iodinating and purifying device and molten salt heat exchange method based on same

A thermal method and molten salt technology, which are applied in furnace control devices, lighting and heating equipment, furnaces, etc., can solve the problems that the temperature cannot be effectively and uniformly controlled, the iodization purification efficiency is low, and the temperature control accuracy is low, and the heating Dual-purpose cooling, uniform and sufficient heat exchange, and high temperature control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

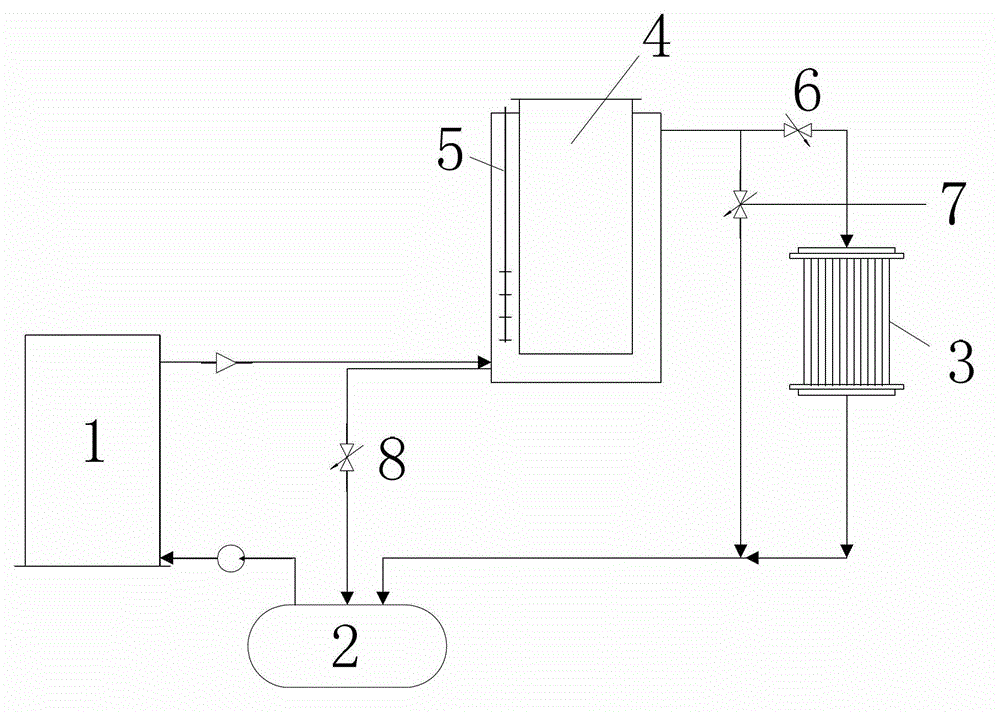

Image

Examples

Embodiment 1

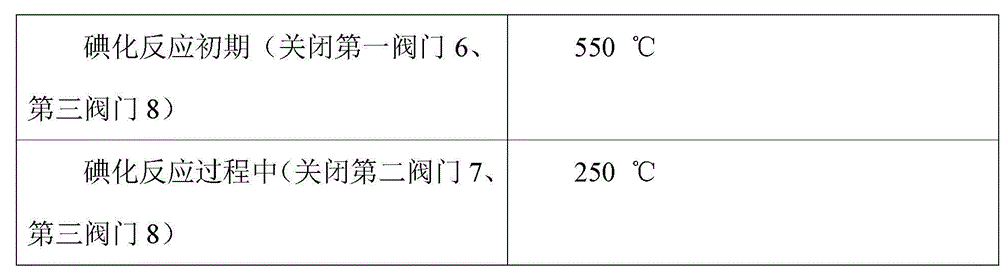

[0025] According to above-mentioned technological process, used molten salt is 45 wt% NaNO 2 and 55 wt% KNO 3 The composition of the mixture, the control conditions are: the temperature of the molten salt at the outlet of the molten salt tank 2 is 200 ° C, the temperature of the molten salt at the outlet of the molten salt heating furnace 1 is 550 ° C, and the first valve 6 is opened. The salt temperature is 250°C.

[0026] The temperature of the realized iodination reaction furnace 4 is as follows:

[0027]

Embodiment 2

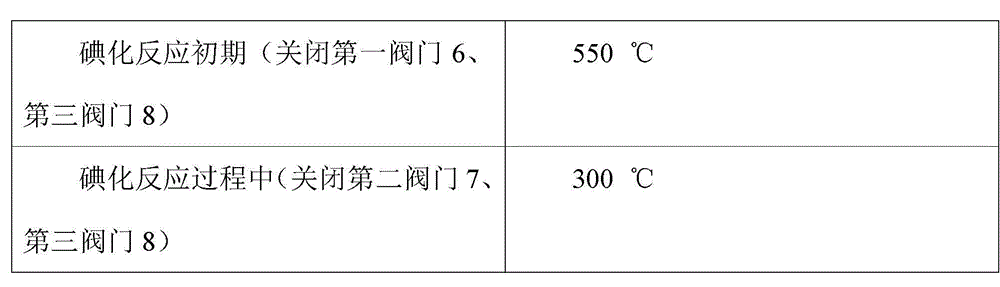

[0029] According to the technological process described in Example 1, the molten salt used is 45 wt% NaNO 2 and 55 wt% KNO 3 The composition of the mixture, the control conditions are: the temperature of the molten salt at the outlet of the molten salt tank 2 is 200 ° C, the temperature of the molten salt at the outlet of the molten salt heating furnace 1 is 550 ° C, and the first valve 6 is opened. The salt temperature is 300°C.

[0030] The temperature of the realized iodination reaction furnace 4 is as follows:

[0031]

Embodiment 3

[0033] According to the technological process described in Example 1, the molten salt used is 45 wt% NaNO 2 and 55 wt% KNO 3 The composition of the mixture, the control conditions are: the temperature of the molten salt at the outlet of the molten salt tank 2 is 200 ° C, the temperature of the molten salt at the outlet of the molten salt heating furnace 1 is 550 ° C, and the first valve 6 is opened. The salt temperature is 550°C.

[0034] The temperature of the realized iodination reaction furnace 4 is as follows:

[0035]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com