Turbine blade with leading-edge concaved cavity

A leading edge and blade technology, applied in the direction of blade support components, engine components, machines/engines, etc., can solve the problems of large thermal stress and uneven temperature field of blades, and achieve thermal stress reduction, simple structure, and temperature distribution uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be further described in detail below in conjunction with the accompanying drawings.

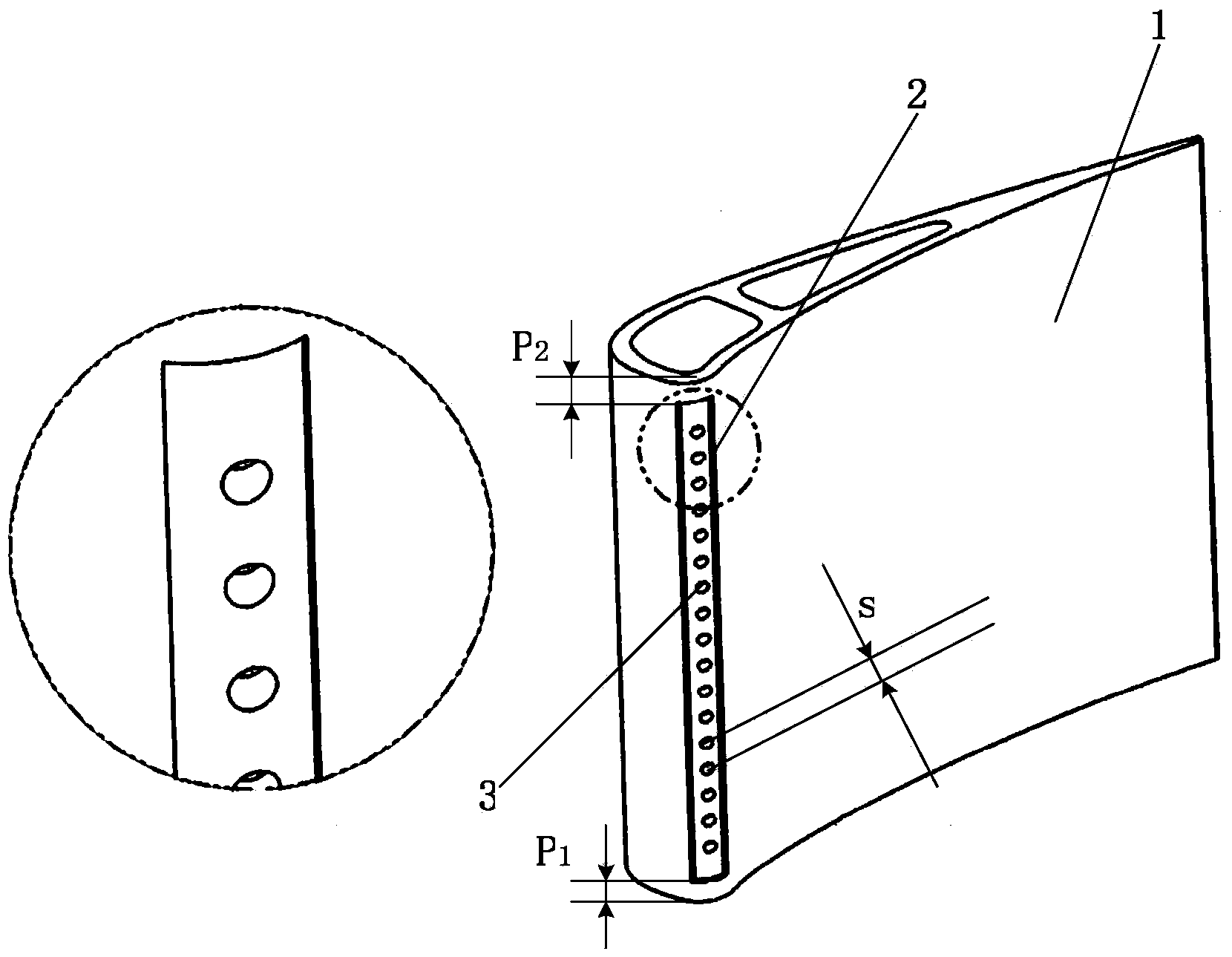

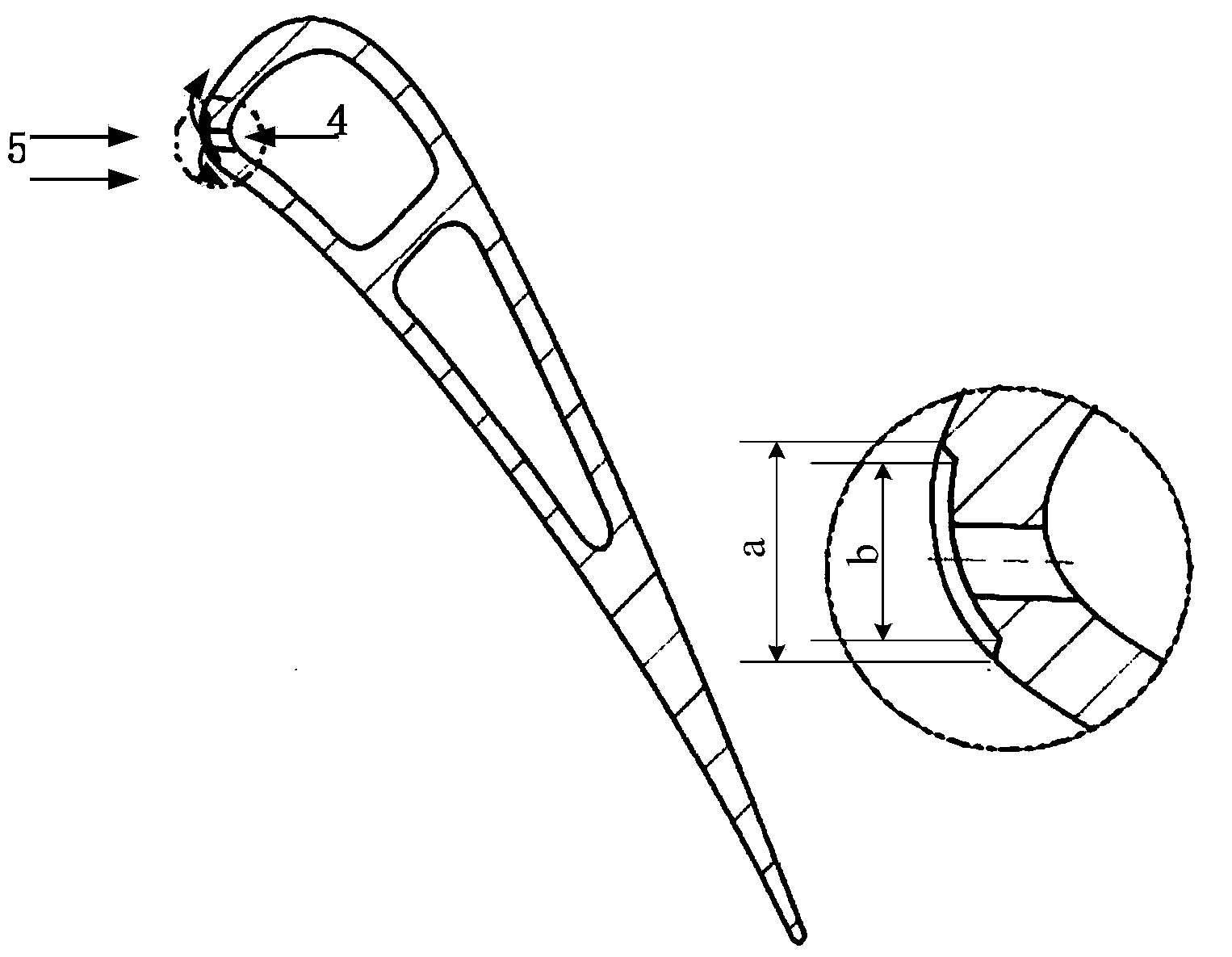

[0009] Such as figure 1 Shown is a schematic diagram of the overall structure of a turbine blade with a leading edge concave cavity structure. The turbine blade includes a blade base (1), a leading edge cavity (2) and an air film hole (3). face, cut a leading edge cavity (2) with a depth of 1 mm to 2 mm inward, and the spanwise width (a) of the opening of the leading edge cavity (2) ranges from 3 mm to 5 mm, forming the bottom surface of the leading edge cavity (2) The profile is the same as that of the original leading edge of the blade. The spanwise width (b) of the bottom surface of the leading edge cavity (2) ranges from 2 mm to 3 mm. The distance between the lower end surface of the leading edge cavity (2) and the blade root (p 1 ) ranges from 6mm to 8mm, the distance between the upper end surface of the leading edge cavity (2) and the tip of the blade...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com