Micro-flow continuous adjustment system at high pressure

A regulation system and flow regulation technology, which is applied to components of pumping devices for elastic fluids, liquid variable capacity machinery, pump control, etc., can solve the problem of increasing retention of raw materials, leakage of conveying medium, and increase of medium compression coefficient and other problems, to achieve the effect of convenient and rapid flow adjustment, ensuring system safety and reducing output flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

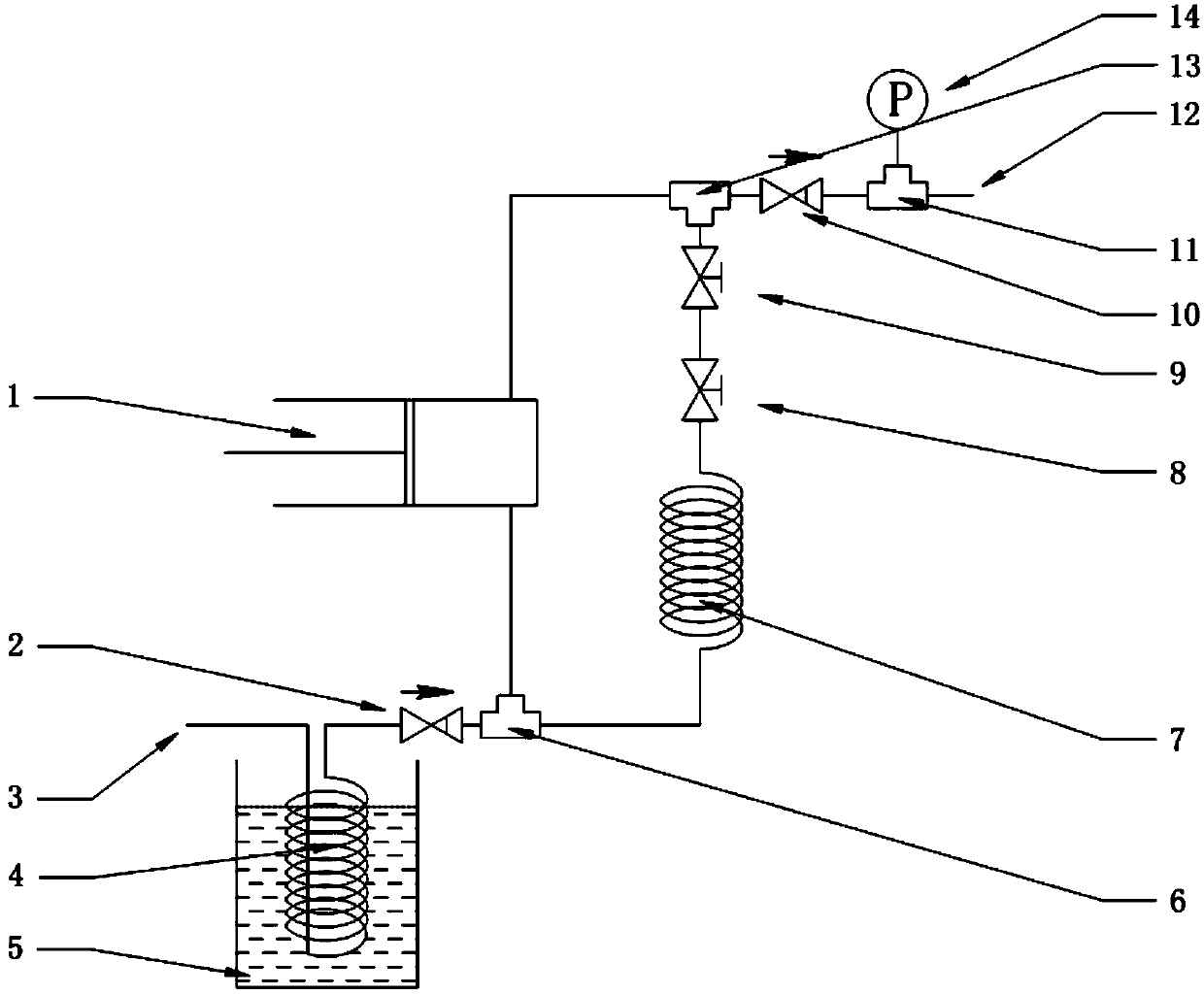

[0017] The cooling system consists of a cooling coil 4 and a low-temperature tank 5; the high-pressure pump delivery system consists of an inlet tee 6, an inlet check valve 2, a high-pressure pump 1, an outlet tee 13, an outlet check valve 10, a pressure gauge tee 11 and The outlet pressure gauge 14 is composed; the flow regulating system is composed of a high-pressure fine-tuning valve 9, a high-pressure fine-tuning metering valve 8 and a flow restrictor 7. For liquefied petroleum gas, carbon dioxide and other media, the upstream 3 of the system is connected to the cooling coil 4 of the cooling structure; for liquid media, the upstream 3 of the system is directly connected to the inlet tee 6 of the high-pressure pump delivery system. The inlet check valve 2 prevents the medium flowing back from the flow restrictor 6 from returning to the upstream 3 of the system. The medium entering from the one-way valve 2 enters the high-pressure pump 1 together with the medium returning fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com