Digestion method and detection method of vanadium-nitrogen-titanium-iron mixed alloy cored wire

A technology of vanadium-nitrogen-titanium-iron and detection method, which is applied in the preparation of test samples, measurement of color/spectral characteristics, thermal excitation analysis, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0025] Digestion of VT cored wire samples

[0026] Weigh 0.1000g of the VT cored wire sample (hereinafter referred to as sample No. 1) into the microwave digestion inner tank, add 1.0mL concentrated nitric acid and 3.0mL concentrated hydrochloric acid, shake the container to disperse the sample evenly, and let it stand for 3 minutes in the open state Time pre-reaction; then wash the container wall with 5mL water in sequence, then add 1.0mL concentrated sulfuric acid drop by drop along the container wall, and continue to pre-react for 1 minute in the open state; finally put the outer tank and cover it And tighten it with a torque wrench to ensure a good seal. Put the sealed digestion container into the microwave digestion furnace according to the instrument operation steps, connect the temperature and pressure sensors, and perform microwave digestion and complexation reaction. This example adopts the microwave reaction method of ramping up the temperature, and the pressure is ...

example 2

[0033] The sample to be digested is 0.1500g VT cored wire sample (hereinafter referred to as sample No. 2), add 2.0mL concentrated nitric acid and 6.0mL concentrated hydrochloric acid, pre-react for 5 minutes; wash the container wall with 8mL water in sequence, and then Add 2.0mL concentrated sulfuric acid drop by drop to the wall of the vessel, and continue the pre-reaction for 2 minutes; finally, close the container for microwave digestion; set the microwave heating condition as ramp temperature rise, and the pressure is less than 800psi; Raise the temperature to 220°C for 3 minutes and keep it warm for 3 minutes to carry out enhanced digestion. After cooling to room temperature, dilute with water and set the volume to 250mL.

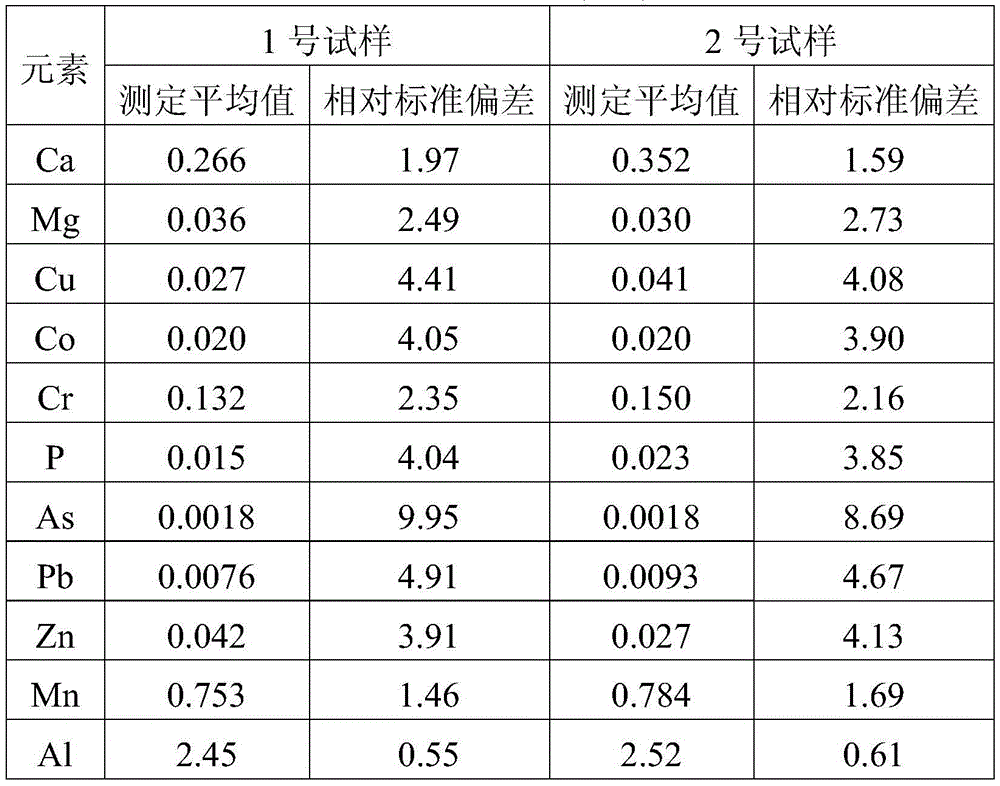

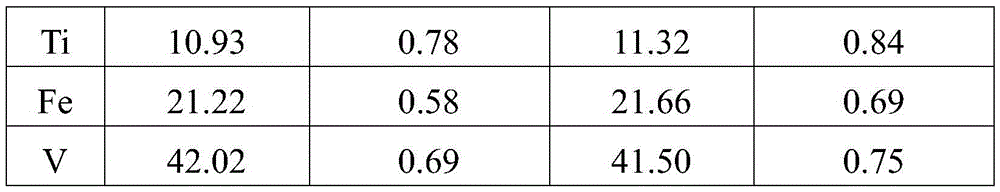

[0034] Other than that, the VT cored wire sample was digested in the same manner as in Example 1 and the solution was detected by ICP-OES.

example 3

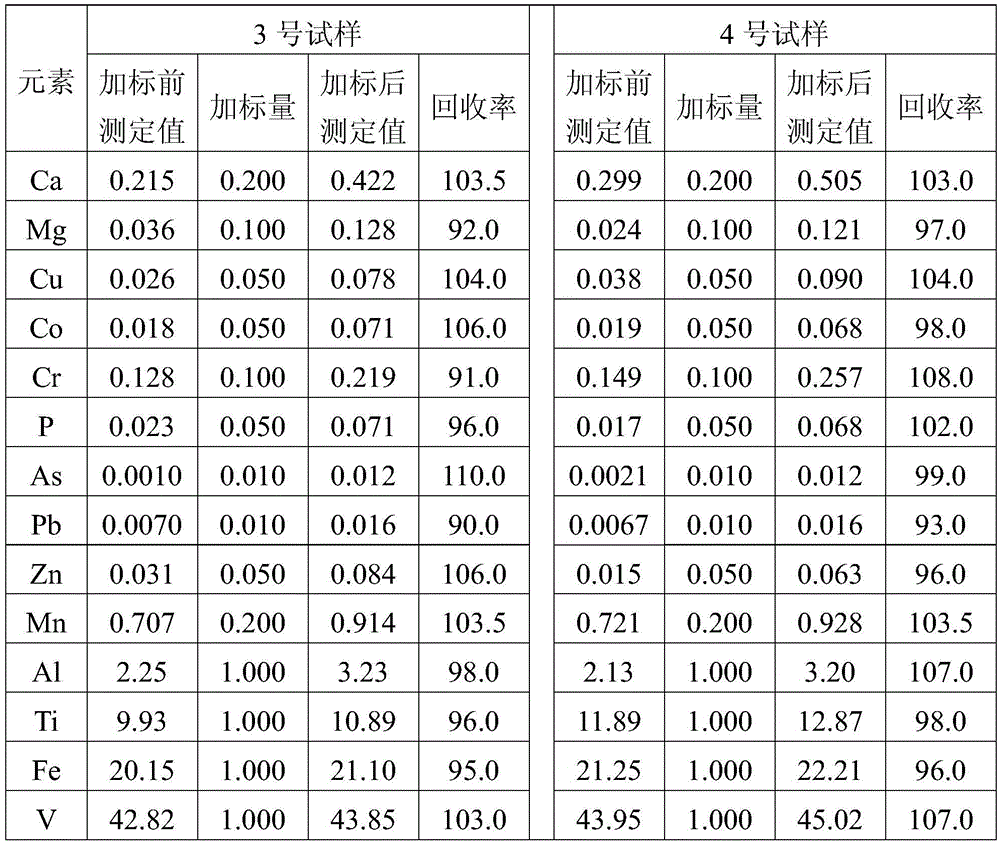

[0036] The digestion sample is 0.1200g VT cored wire sample (hereinafter referred to as sample No. 3), add 1.5mL concentrated nitric acid and 4.5mL concentrated hydrochloric acid, and pre-react for 4 minutes; wash the container wall with 6mL water sequentially, and then Add 1.5mL concentrated sulfuric acid drop by drop, and continue the pre-reaction for 1 minute; finally, close the container for microwave digestion; set the microwave heating condition as ramp temperature rise, and the pressure is less than 800psi; first, heat up to 185°C for 13 minutes and keep it warm for 9 minutes for high-temperature digestion, and finally heat up for 2 minutes Heat at 215°C and keep it warm for 2 minutes for enhanced digestion. After cooling to room temperature, dilute with water to 200mL.

[0037] In addition, the VT cored wire sample was digested in the same manner as in Example 1 and subjected to ICP-OES detection.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com