Large-size high-precision simple shear apparatus structure

A high-precision, single-shear technology, applied in the direction of using a stable shear force to test the strength of materials, can solve problems such as shortening the service life, insufficient accuracy, easy damage, etc., to achieve stable operation and improved test accuracy. , The effect of convenient installation and debugging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

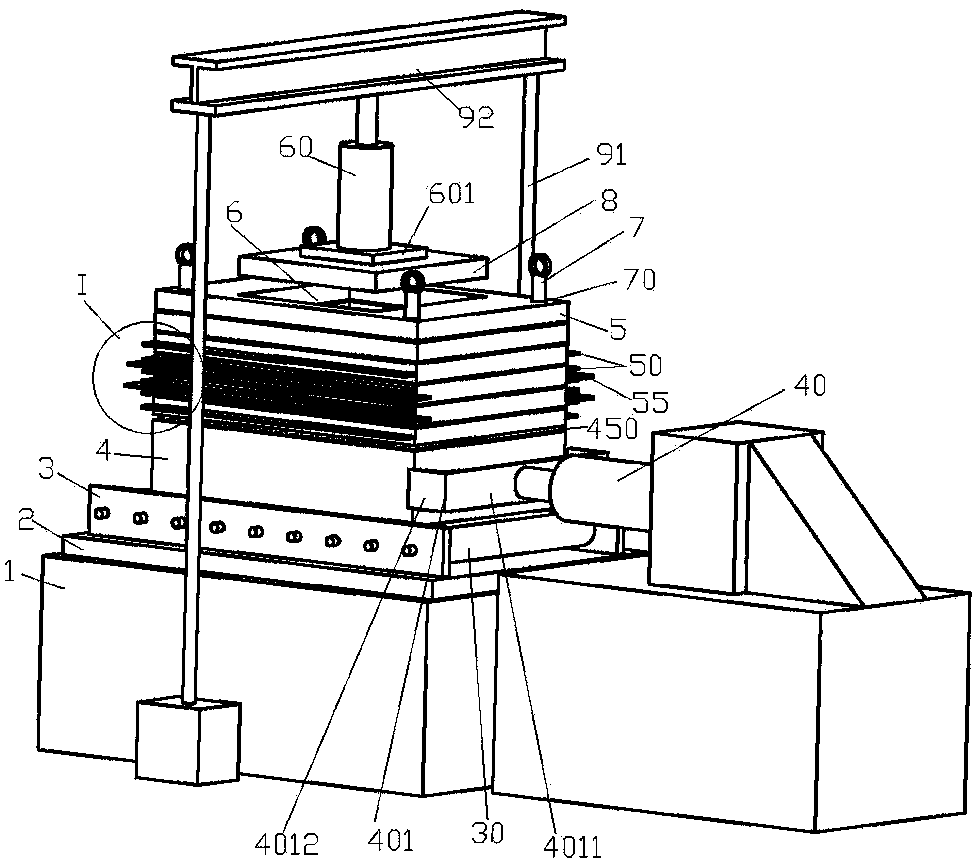

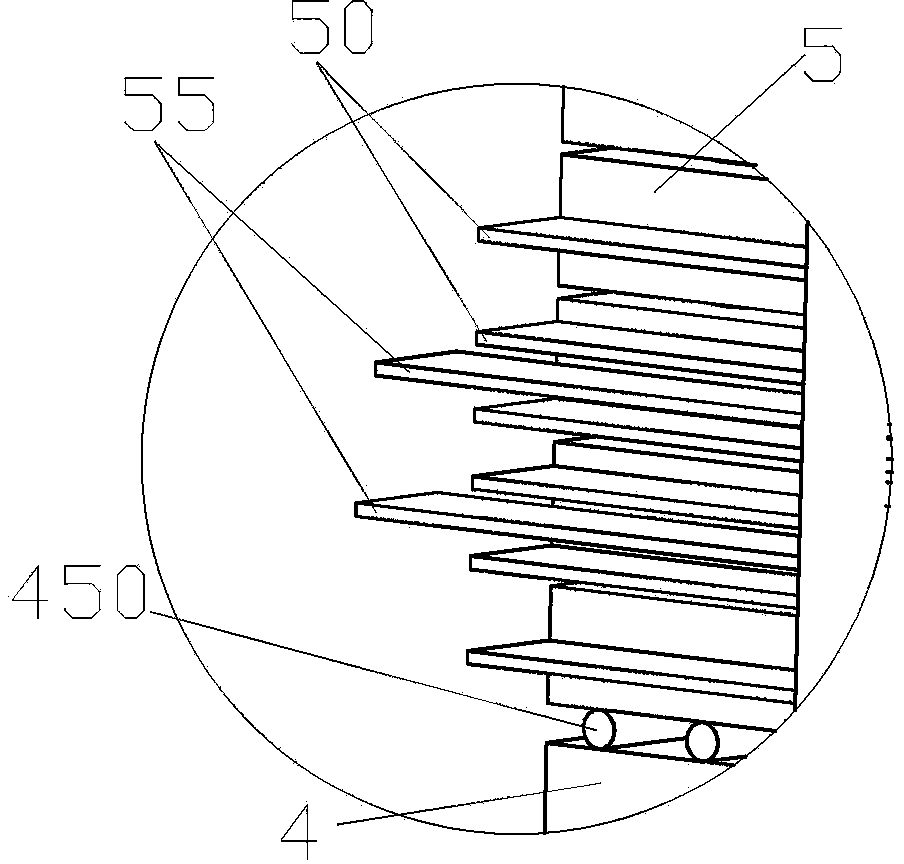

[0023] Example 1, such as figure 1 , 2 As shown, a large-scale high-precision single-shear instrument structure includes a basic platform 1, on which a rectangular metal flat plate 2 is provided. The upper surface of the metal flat plate 2 is integrally connected with two parallel guide plates 3 forming a guide channel. , A row of rollers 30 is arranged between the two guide plates 3, a rectangular parallelepiped concrete block 4 is preset above the row of rollers 30, and a plurality of stacked plates 5 are stacked on the upper part of the concrete block 4, and the stacked plates 5 are frame-shaped plates And the inner frame and the outer frame are rectangular, all the stacked plates 5 and the concrete blocks 4 enclose a rectangular parallelepiped-shaped storage bin 6, and the stacked plates 5 are provided with positioning holes 70 and equipped with positioning bolts 7. The pattern storage compartment 6 is also equipped with a pressure-transmitting plate 8 that matches the cros...

Embodiment 2

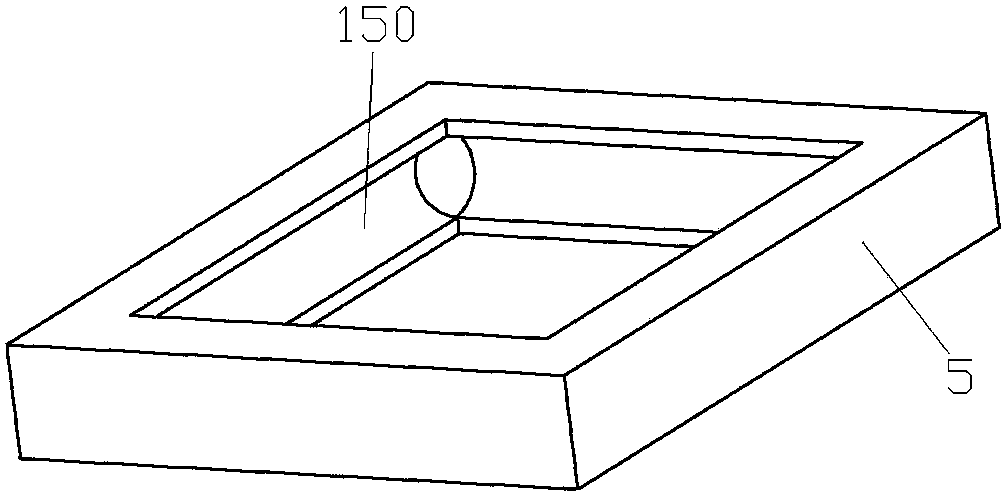

[0026] Example 2, such as image 3 As shown, the difference from Embodiment 1 is that horizontal strip arc-shaped grooves 150 are opened along the inner frame surface of the stack 5, and one or more than one can be provided, and adjustments can be made according to actual requirements and test summary.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com