Concrete unilateral freeze thawing tester

A technology for concrete and testing machines, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of large differences in test piece boxes and low temperature accuracy of test piece boxes, and achieve the effect of improving temperature accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with accompanying drawing and embodiment:

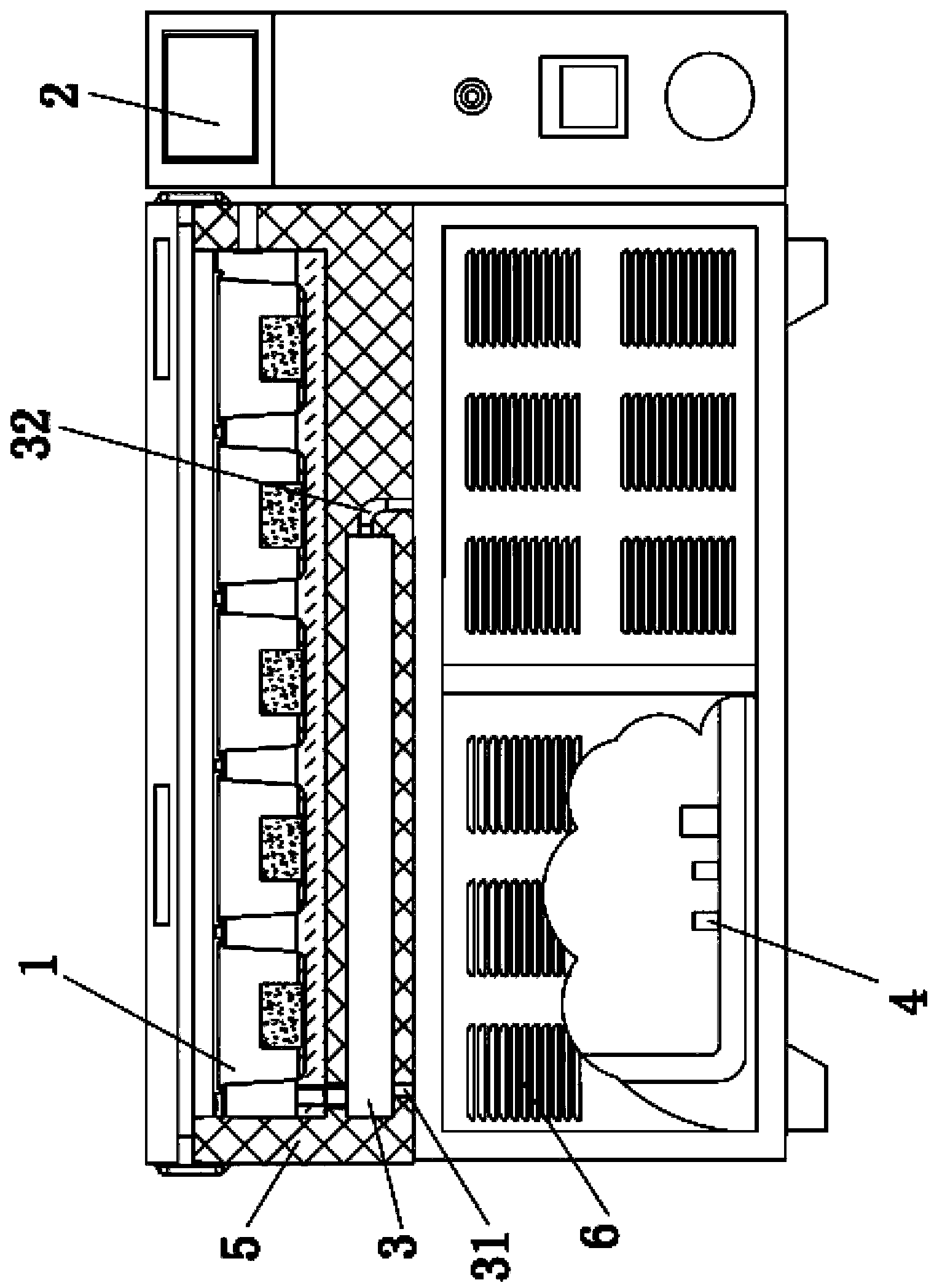

[0016] Such as Figure 1-2 As shown, a concrete unilateral freeze-thaw test machine includes a test piece box 1, a heat dissipation system 6, and a control cabinet 2; a refrigeration tank 3 is horizontally arranged below the test piece box 1; square. Cooling water is housed in the cooling tank 3 the inside. One end of the bottom of the refrigeration tank 3 is connected to an input pipe 31, and the other end is connected to an output pipe 32, and the input pipe 31 is connected to the output pipe 32 through a circulating water pump (not shown in the figure); The bottom of the system 6 is provided with a solenoid valve group 4 , the first end 22 of the solenoid valve group 4 is connected to the specimen box 1 , and the second end 21 is connected to the refrigeration tank 3 .

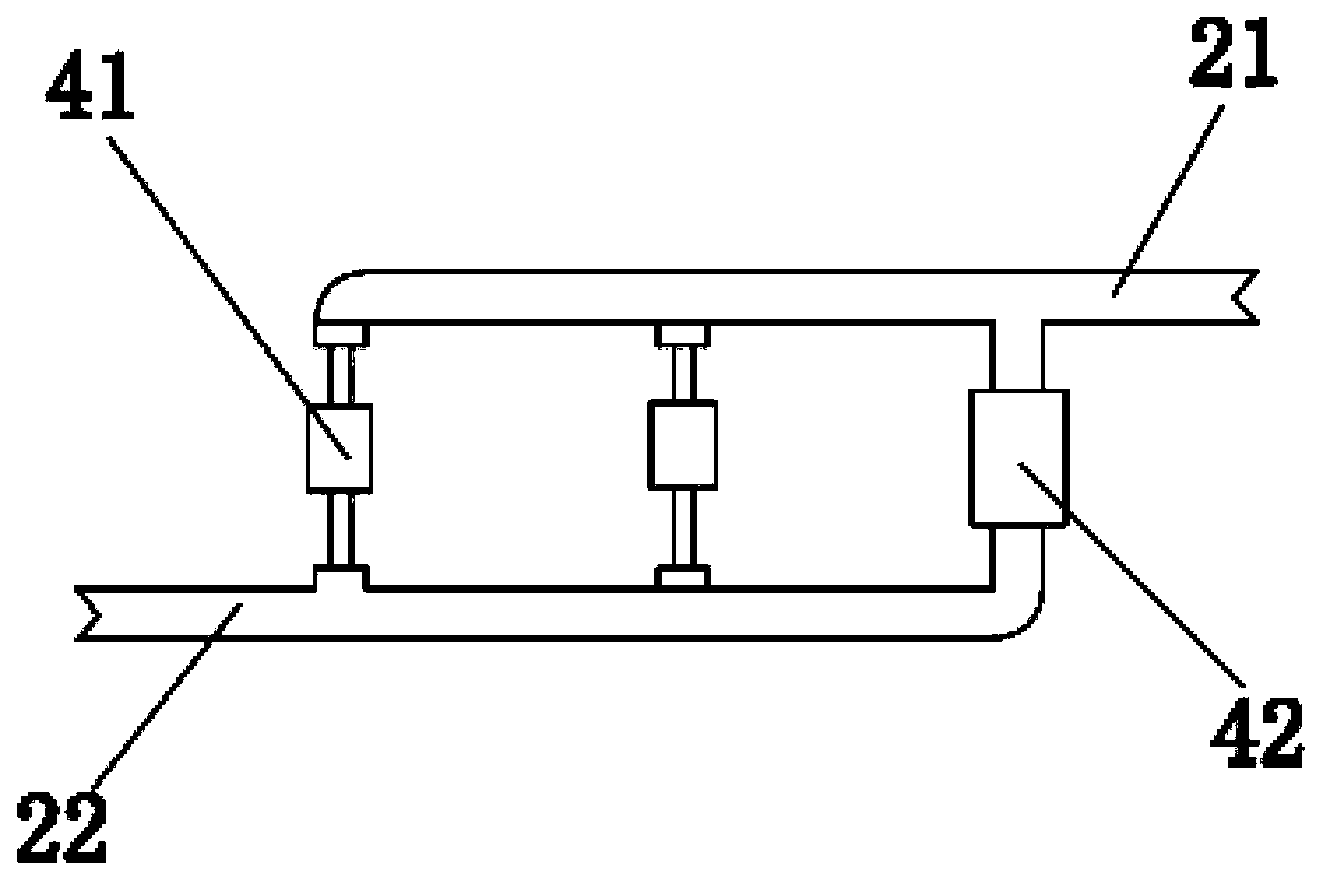

[0017] The solenoid valve group 4 includes three solenoid valves arranged side by s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com