Data processing method based on servo drive unit

A servo drive unit and data processing technology, applied in the direction of digital variable display, etc., can solve problems such as difficult to display low repetition rate signals, low electrical signals, difficult to display frequency, etc., and achieve friendly graphical human-computer interaction interface, plug-in Ready-to-use, accurate data collection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

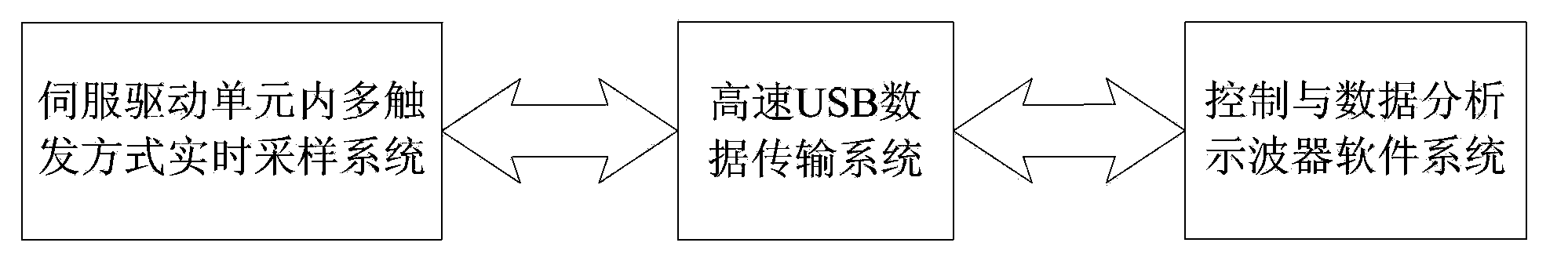

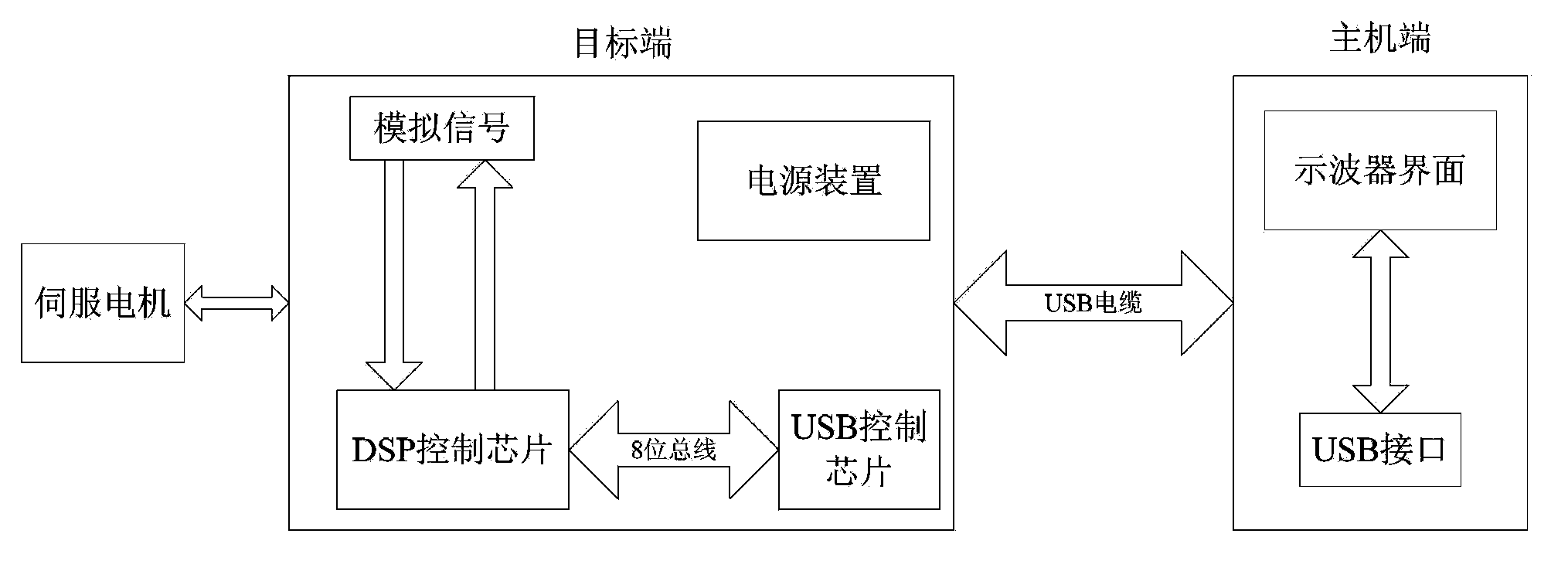

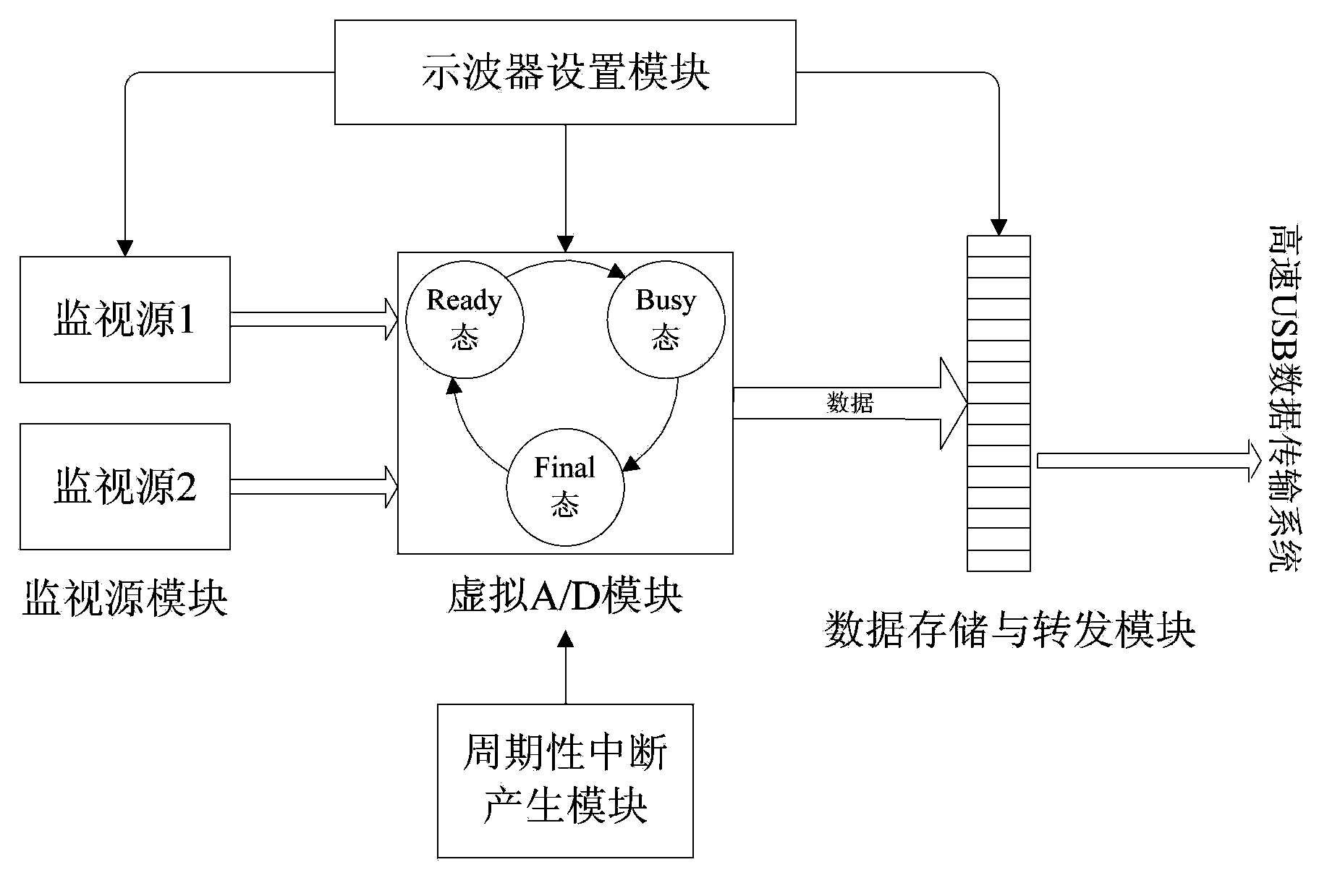

[0041]The technical scheme of the present invention is: directly on the internal DSP chip TMS320F28335 of the servo drive unit, a virtual A / D module is pushed, and the virtual module is driven by a periodic interruption of a fixed frequency, and the data to be observed is collected under the effect of the interruption. It can be an actual physical quantity, such as the A-phase current of the motor, or it can be a result calculated by a motor control algorithm at that moment by the servo drive unit. Then the collected data is stored in the FIFO queue, and the data in the FIFO is sent to the PC through the high-speed USB interface chip PDIUSBD12, and finally the relevant data is reconstructed by the PC into time-domain waveform images and spectrograms to calculate the data Peak time, overshoot, and steady-state error are displayed on the PC-side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com