Scheduling method and system for regular maintenance items

A technology for regular maintenance and projects, applied in the professional field of nuclear power plants, it can solve the problems of relying on labor, incompleteness, and affecting the comprehensive retrieval of project scheduling information, so as to reduce workload and improve labor efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

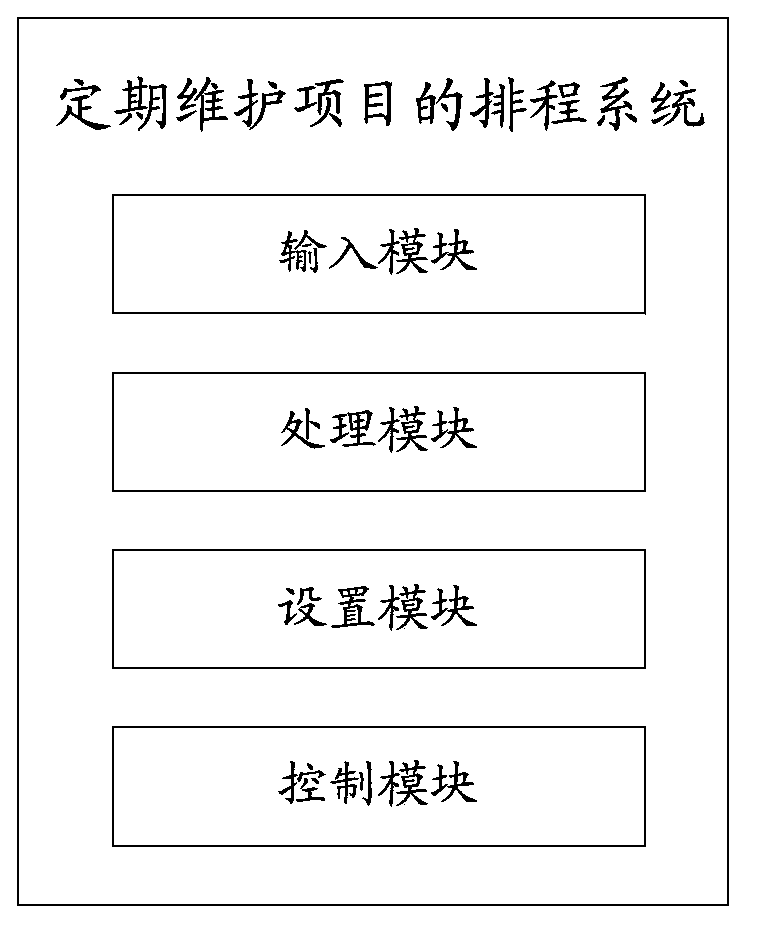

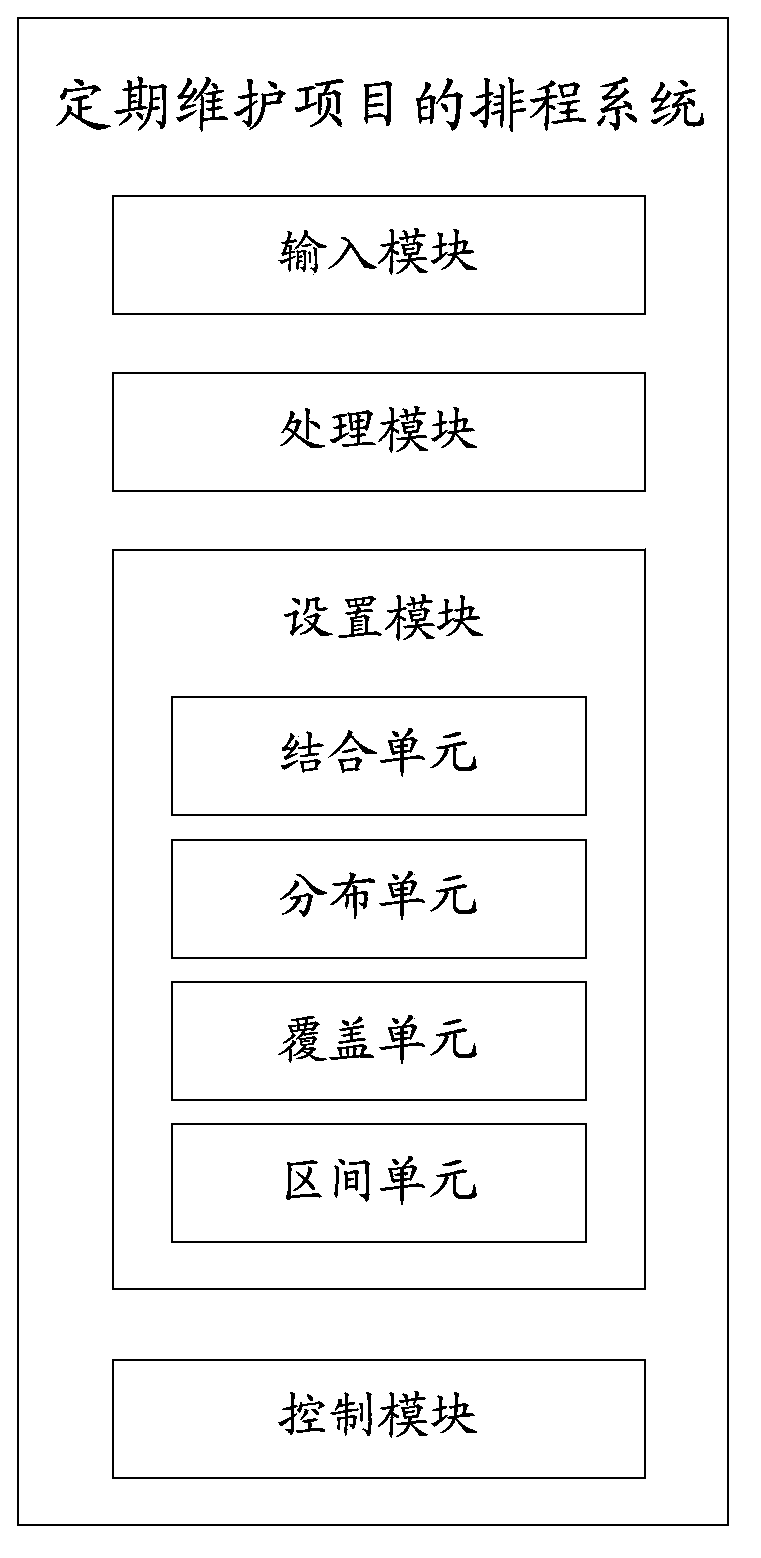

[0058] like figure 1 , figure 2 As shown, the scheduling system of the regular maintenance item of the present application, an embodiment thereof, includes: an input module, a processing module, a setting module and a control module. The input module is used to import the information of the regular maintenance items from the database into the spreadsheet; the processing module is used to select the preset regular maintenance items in the spreadsheet, and determine the schedule of the preset regular maintenance items according to the information of the preset regular maintenance items The setting module is used to create a logical relationship between the preset regular maintenance item and the related regular maintenance item; the control module is used to automatically set the schedule of the related regular maintenance item according to the logical relationship.

[0059] The setting module includes a combining unit for setting the related periodic maintenance item and the ...

Embodiment approach

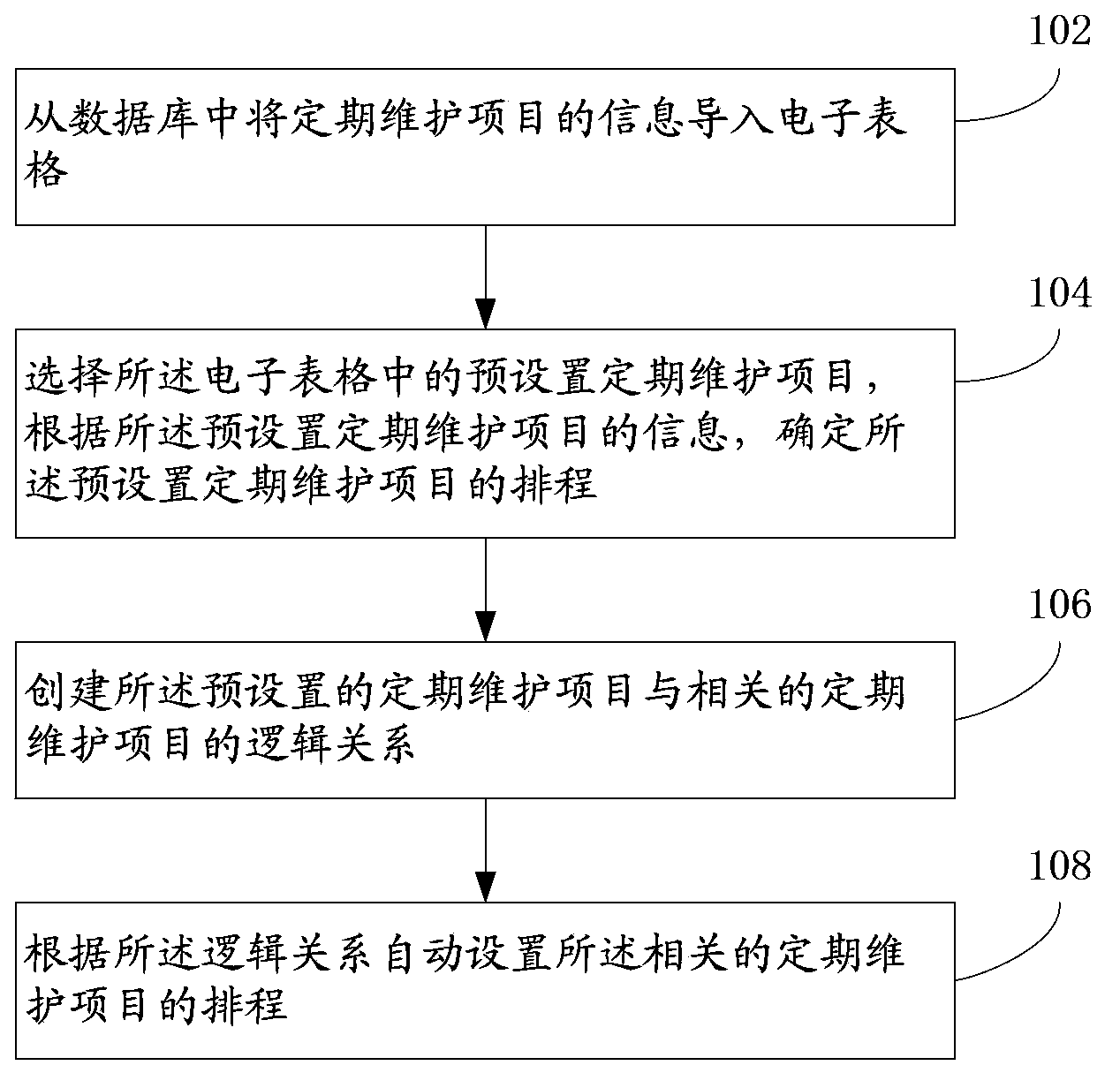

[0066] like image 3 As shown, the scheduling method of the regular maintenance project of the present application, an implementation manner thereof, includes the following steps:

[0067] Step 102: Import the information of the regular maintenance item from the database into the spreadsheet; the information of the regular maintenance item includes the start date.

[0068] Step 104: Select the preset regular maintenance item in the spreadsheet, and determine the schedule of the preset regular maintenance item according to the information of the preset regular maintenance item; classify the schedule description information, convert it into a standardized logical relationship, and store it. In a special database, the centralized creation, query and modification of scheduling logical relationship and remark information can be realized.

[0069] Step 106: Create a logical relationship between preset regular maintenance items and related regular maintenance items;

[0070] Step 1...

specific Embodiment approach

[0089] like Figure 5 As shown, the scheduling method of the regular maintenance project of the present application, a specific implementation thereof, includes the following steps:

[0090] Step 302: Process starts

[0091] Step 304: Establish a regular maintenance project, which can be specifically executed in the preventive maintenance management module of the ERP or EAM software.

[0092] Step 306: Export and save the periodic maintenance items established in Step 304 in the form of a list as a spreadsheet using the ERP or EAM software report.

[0093] Step 308 : In the electronic form, establish a scheduling logical relationship between items through a preset relationship definition, or modify an existing item scheduling logical relationship.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com