Inductance element and its manufacturing method

A technology of inductance components and manufacturing methods, which is applied in the direction of electrical components, inductance/transformer/magnet manufacturing, transformer/inductor parts, etc., can solve the problems of delamination of iron powder core, change of magnetic couple set distance, displacement of inductance value, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

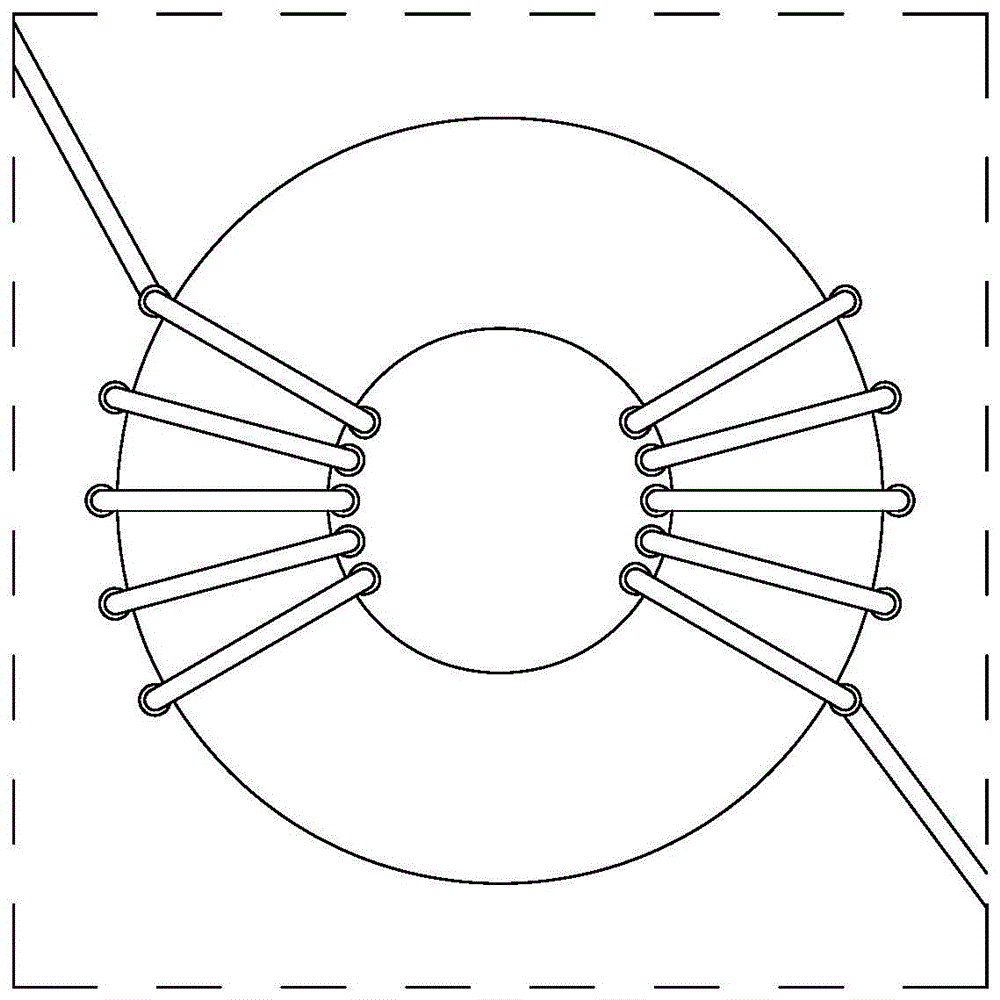

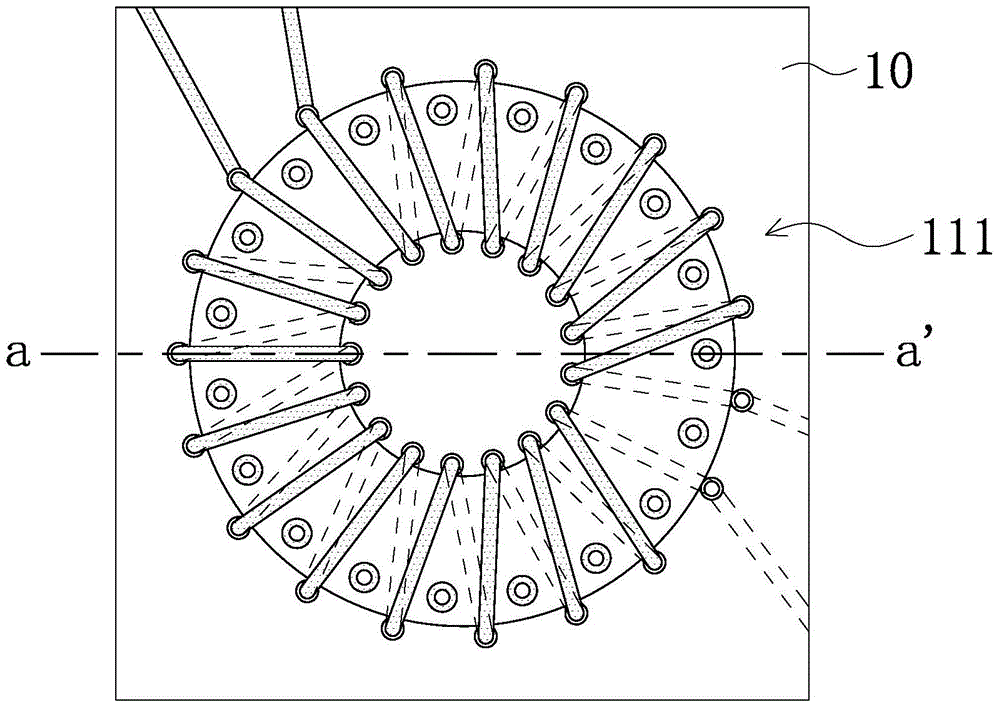

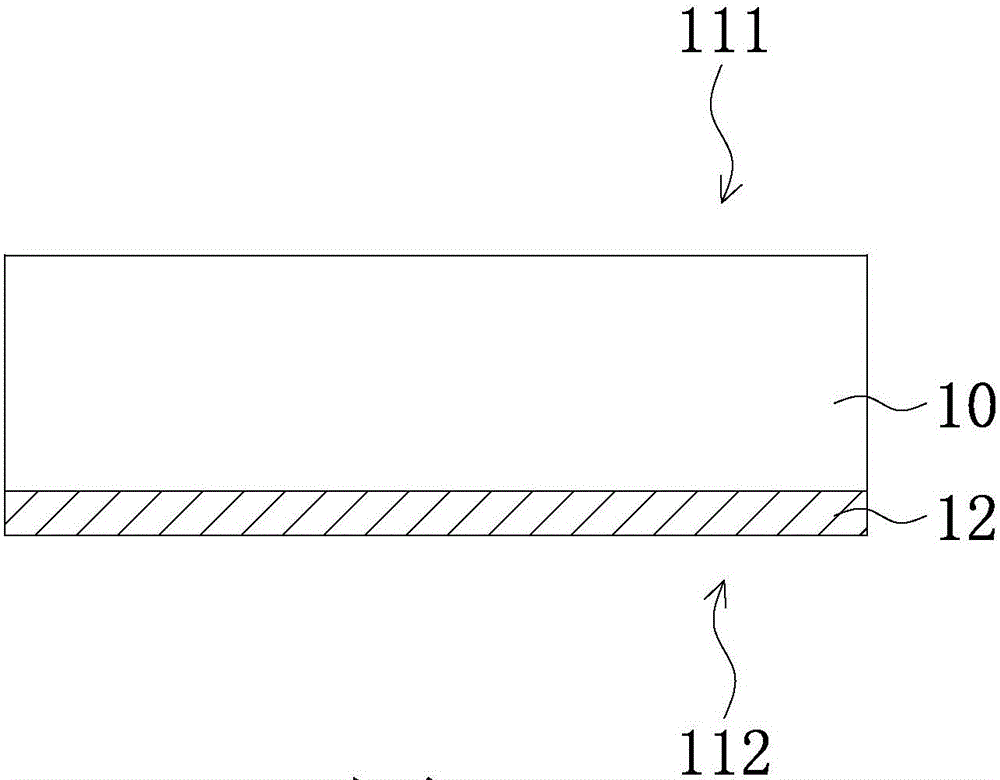

[0023] Figure 2A to Figure 2B It is a flow diagram of an inductance element and its manufacturing method drawn according to an embodiment of the present invention. A is a top view, and B is a schematic cross-sectional view after cutting along a and a' in the top view A.

[0024] Please refer to FIG. 2, the base is a flat insulating substrate 10, and the bottom is a lower conductive material layer 12. For the convenience of distinguishing directions, the side of the lower conductive material layer in FIG. 2 is defined as the bottom surface 112; Surface 111. In one embodiment of the present invention, an epoxy resin glass fiber board (FR4) is used as the substrate, and copper foil is used as the lower conductive material layer 12 below. Figure 2A The figure in is the position and the completed shape for the follow-up predetermined steps, where the dotted line part is a schematic diagram of the completion of the bottom surface 112, the part filled with solid lines is a schema...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com