Surface treatment method for hydrogen storage alloy

A hydrogen storage alloy and surface treatment technology, which is applied in metal material coating technology, liquid chemical plating, coating, etc., can solve the problems of poor stability, poor reactivity, and easy oxidation of cuprous compounds, and achieve high performance Excellent, effective and reasonable use, and performance-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

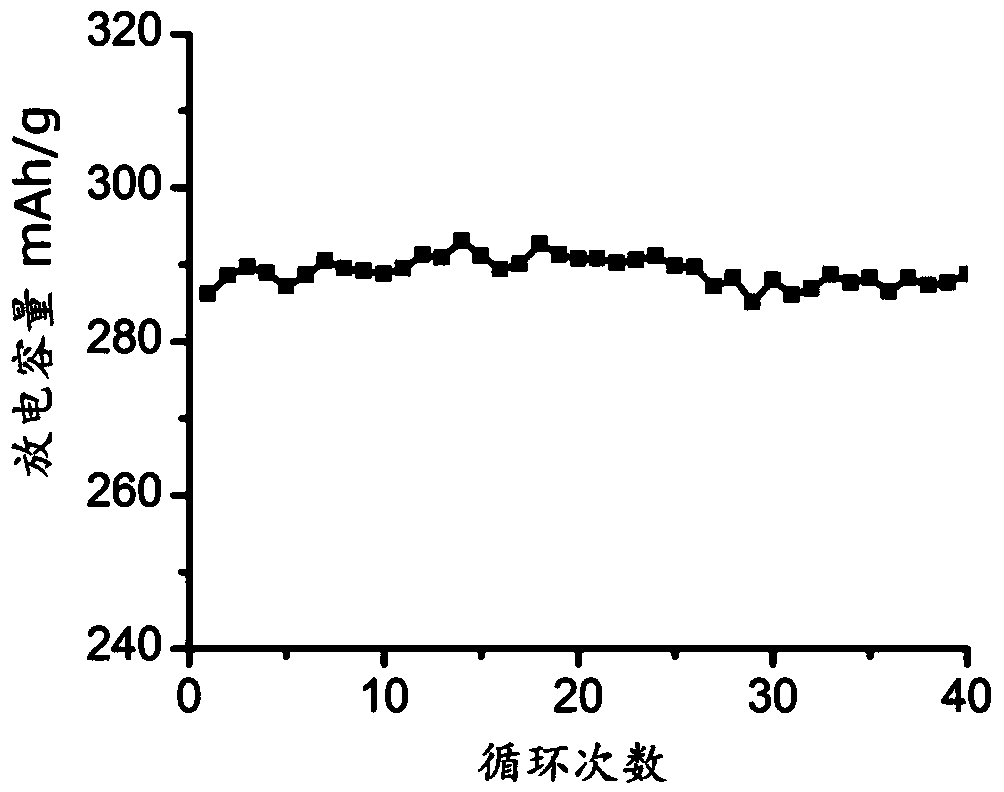

[0026] Example 1:

[0027] First, weigh a certain amount of hydrogen storage alloy powder and grind it through a sieve to control its particle size in the micron level; under the protection of nitrogen, add an aqueous solution of HF and NaF with a pH of about 0.05 mol / L and a pH of 3 to control the reaction process. The pH value of the medium solution is not less than 6, and react at room temperature for 5 minutes to obtain a suspension of hydrogen storage alloy powder from which the surface oxide film or hydroxide film is removed. After filtering or centrifuging the above suspension to remove the solution, add a certain amount of air-removed water to the obtained alloy solid (the amount of water is at least enough to stir the solid), raise the temperature to 50 ℃, and then add CuCl while stirring For the water dispersion, the CuCl mass is controlled to be 0.125 times the mass of the hydrogen storage alloy powder, and the sum of the masses of the hydrogen storage alloy powder and...

Example Embodiment

[0030] Example 2:

[0031] First, under the protection of argon, weigh a certain amount of hydrogen storage alloy powder with a particle size of several microns, and add 0.1 mol / L, pH 2 hexamethylenetetramine hydrochloride and hexamethylenetetramine For the aqueous dispersion of amine solution, the pH value of the solution during the reaction is controlled to not be lower than 5, otherwise more solid hexamethylenetetramine hydrochloride needs to be added. The reaction was carried out at room temperature for 10 minutes to obtain a suspension of hydrogen storage alloy powder from which the surface oxide film or hydroxide film was removed. Filter or centrifuge the above suspension to remove the solution, then add a certain amount of air-removed water to the obtained alloy solid (the amount of water added is at least to be able to stir the solid), heat up to 100 ℃, and then add CuI water dispersion while stirring Liquid, the mass of CuI is controlled to be 0.2 times the mass of the ...

Example Embodiment

[0032] Example 3:

[0033] First, weigh a certain amount of hydrogen storage alloy powder under the protection of argon, and add a 0.2mol / L, pH 6 mixed aqueous solution of ammonium chloride and ammonia to control the pH of the solution to not less than 6 during the reaction. React at room temperature for 60 minutes to obtain a suspension of hydrogen storage alloy powder from which surface oxide film or hydroxide film has been removed. Secondly, under the protection of argon, filter or centrifuge the above suspension to remove the solution, and then add a certain amount of de-aired water to the obtained alloy solid (the amount of water added is at least enough to stir the solid), and then stir at room temperature. Join Cu 2 Water dispersion of O to control Cu 2 The mass of O is 0.01 times the mass of hydrogen storage alloy powder, and the hydrogen storage alloy powder and Cu 2 The sum of the mass of O is 0.12 times the mass of water removed from air. Due to Cu 2 O has poor reacti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Discharge capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap