Self-synchronizing trigger high capacity discharging gap

A technology of discharge gap and trigger gap, which is applied in the field of self-synchronized triggering of large-capacity discharge gap, can solve the problems of increasing the complexity of the control system and power pulse system, increasing the cost of the gap and related auxiliary equipment, and reducing the reliability of the gap action. Basically stable operating characteristics, reduced device cost and complexity, and improved device reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

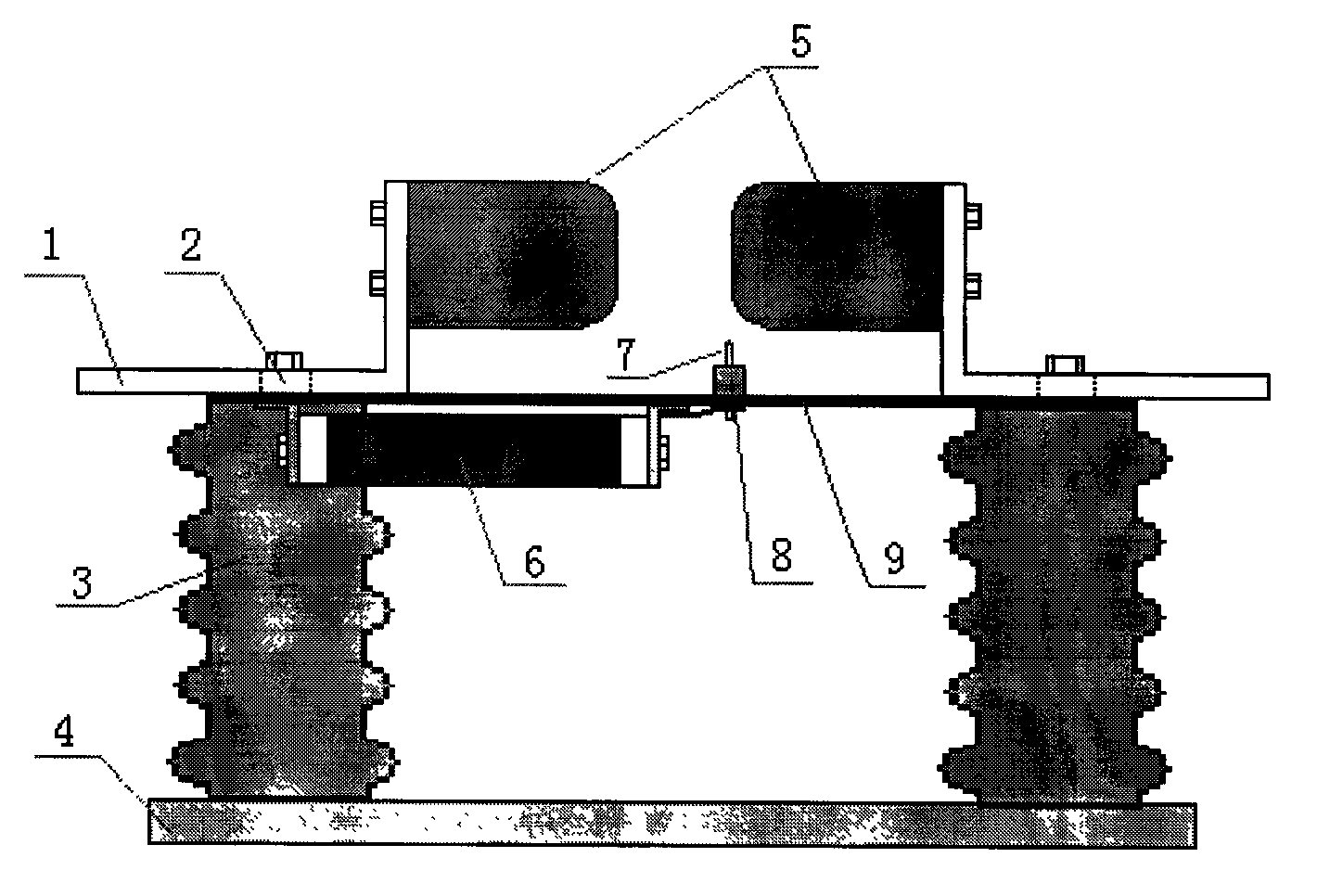

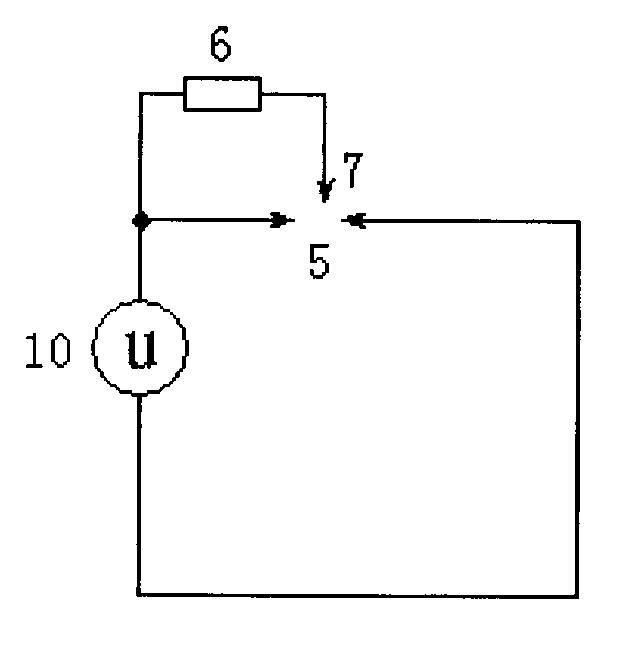

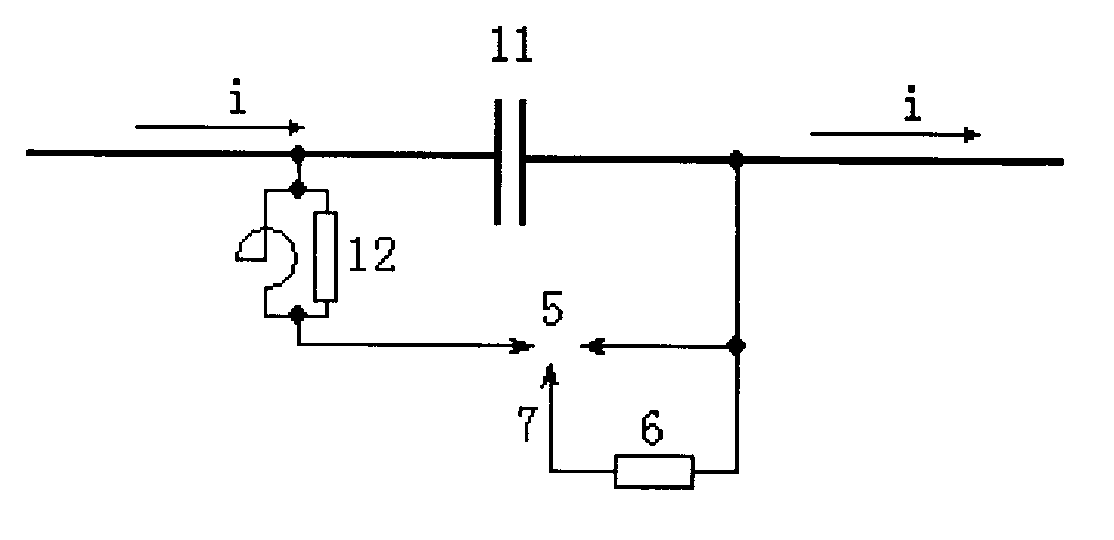

[0013] figure 1 It is a structural schematic diagram of the present invention, the main discharge electrode 5 is installed on the conductive row 1, connected and fixed with the support insulator 3 through the long slot 2, and the support insulator is fixed on the base 4, and the above long slot is used to adjust the distance of the main discharge gap . The arc-resistant insulating plate 9 is overlapped between the two insulators, the impedance device 6, the trigger electrode 7 and the electrode seat 8 are fixed on the arc-resistant insulating plate 9, and the position and distance of the trigger electrode can be adjusted through the electrode seat 8. figure 2 The device 10 in represents the voltage applied across the main discharge gap. Since the distance between the main discharge gap and the trigger gap can be adjusted separately, the protection characteristics of the discharge gap can be artificially changed according to the needs of the application. At the same time, si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com