Multi-magnification automatic microscopic imaging method and device

A microscopic imaging and fully automatic technology, applied in the field of optical imaging, can solve the problems of low accuracy of inspection results, heavy workload of inspectors, and low degree of automation, so as to reduce time costs and inspection personnel needs, and reduce inspection costs. , the effect of avoiding motion errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

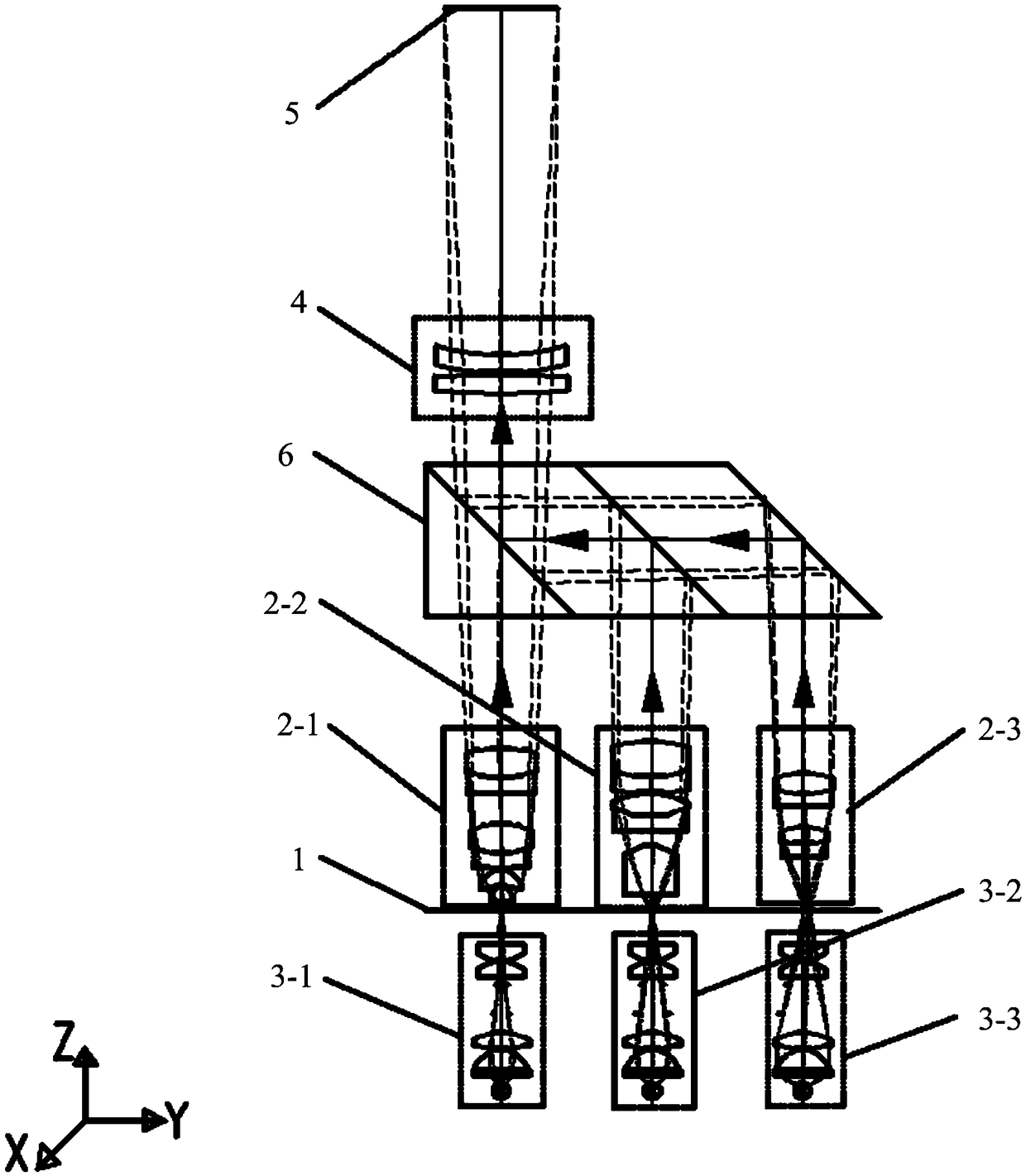

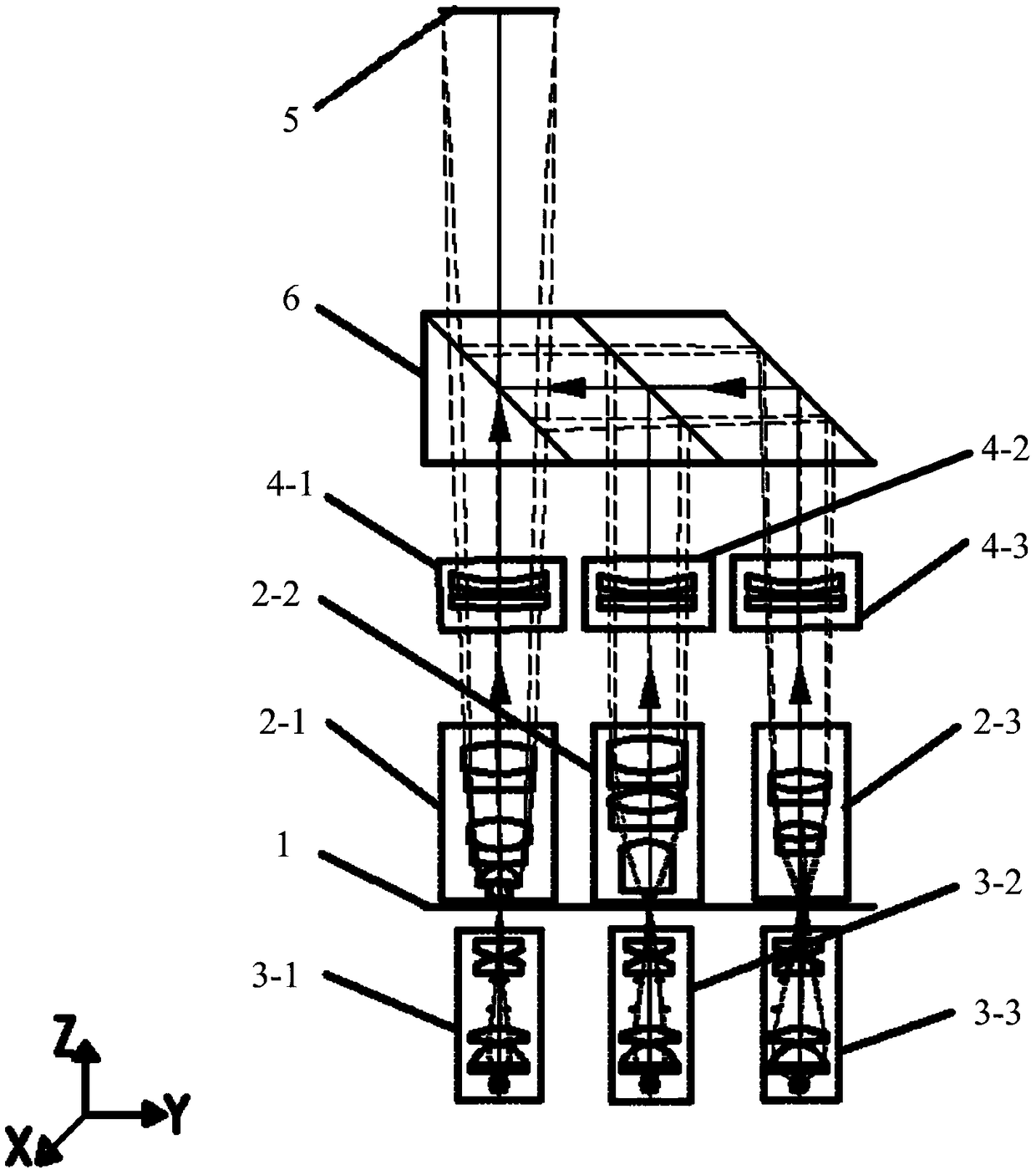

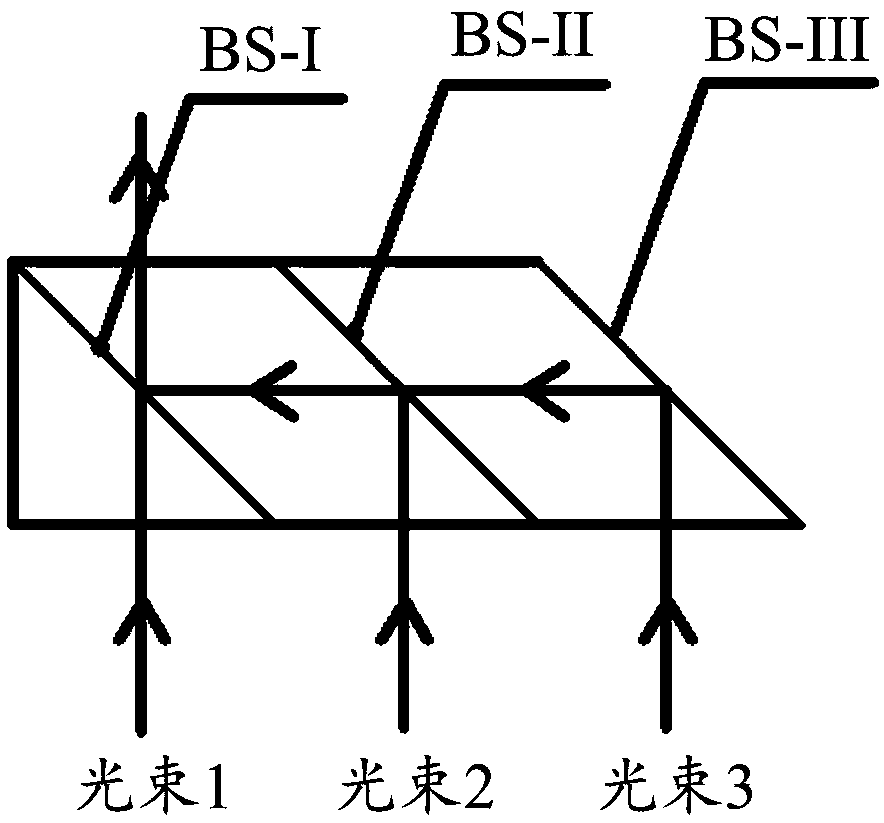

[0023] In one of the examples, as Figure 1-Figure 3 As shown, the multi-magnification automatic microscopic imaging device includes a three-dimensional motion platform 1, at least two microscopic objective lenses, an illumination unit, a tube lens 4, an imaging unit 5, a beam integration component 6 and a fully automatic control unit.

[0024] Specifically, the three-dimensional motion platform 1 can also be called a sample stage, which is used to carry the sample of the measured object. The three-dimensional motion platform 1 can perform three-dimensional independent movement under the control of a fully automatic control unit, and is parallel to the direction of the optical axis of the microscope (that is, the Z direction). ) has the highest motion accuracy, which can reach the micron level or even higher.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com