Ecological management method of gold ore tailings after hydrometallurgy

A technology of hydrometallurgy and ecological management, applied in the field of smelting, can solve problems affecting roads and surrounding villages, fertile fields and forests, easy to form sandstorms, dust, human respiratory hazards, etc., to achieve low maintenance and management costs, and is conducive to growth and construction Effect with few seasonal restrictions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

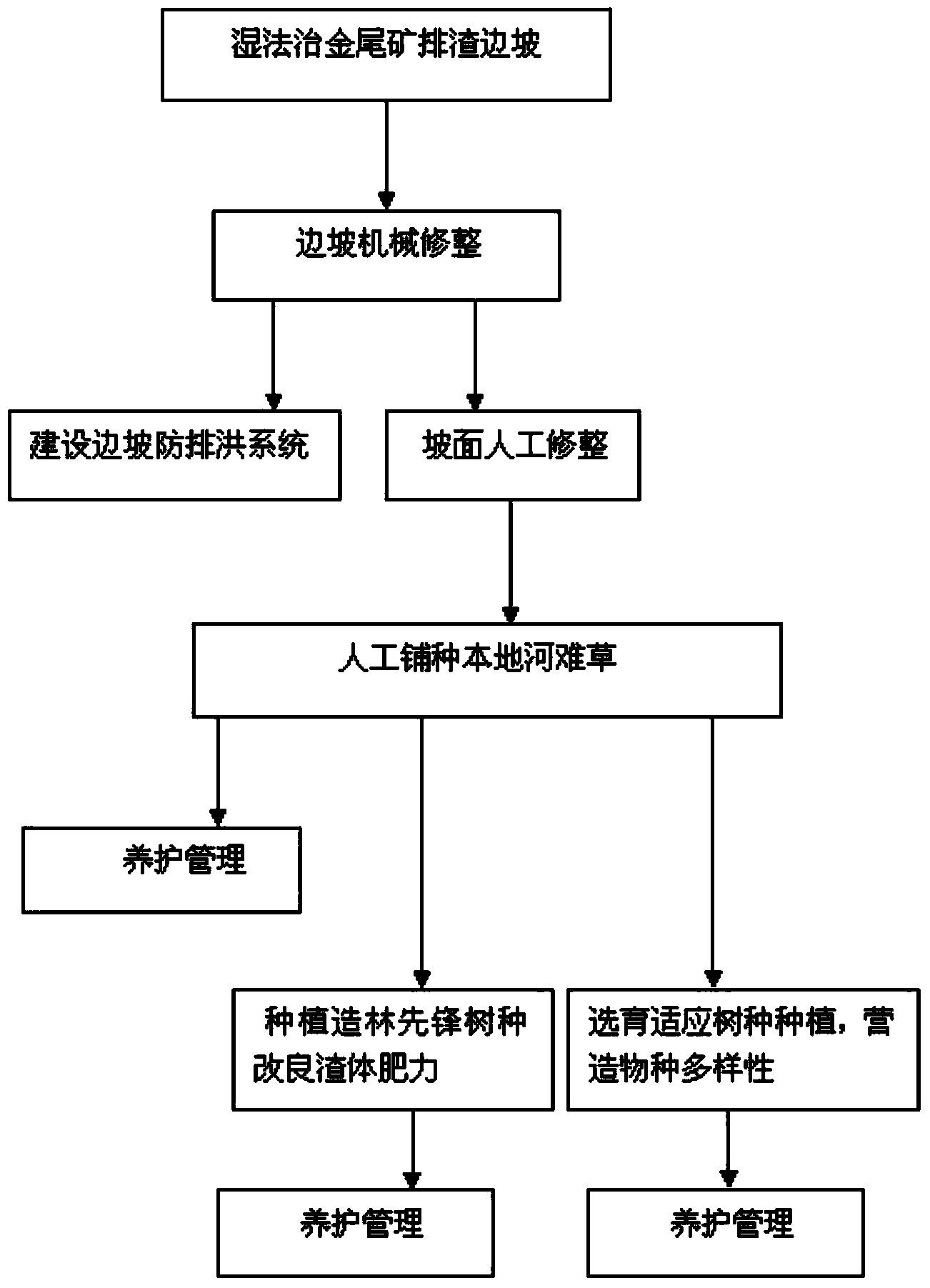

Method used

Image

Examples

Embodiment 1

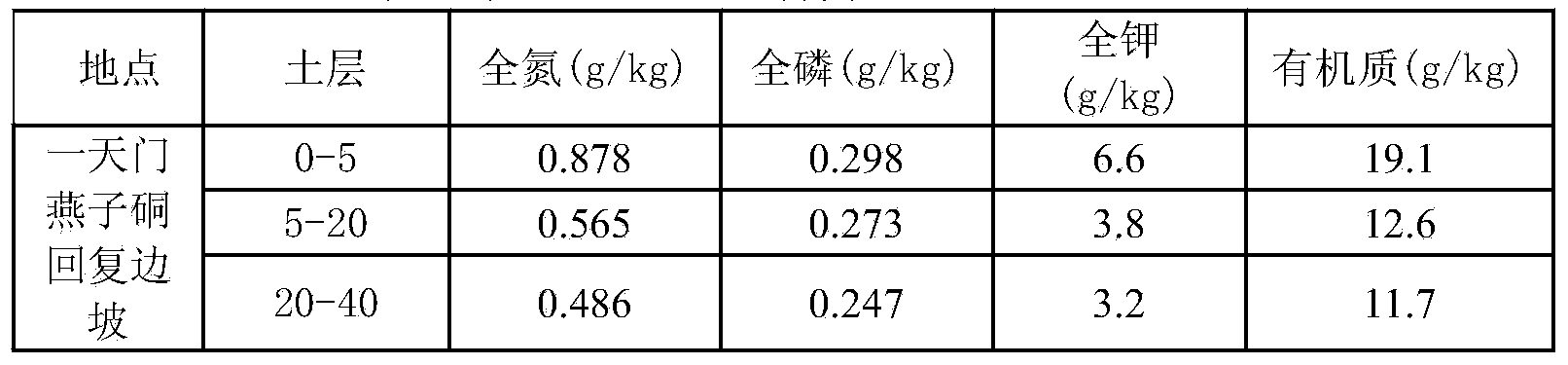

[0018] In the first step, after spraying by hydrometallurgical spraying technology, the tailings waste residue needs to be pulled to the specified discharge point for accumulation. The tailings residue of this kind of gold mine is crushed into irregular crushed ore of 8-20cm. Therefore, the particle size is small and relatively uniform, weakly alkaline, and the pH value is 8.0-9.5. The main body of the soil is a variety of mineralized and oxidized medium-fine-grained granite, gold minerals have been leached and recovered, and the content of heavy metals such as copper and silver is extremely low. . It has loose structure, low strength, high sand and gravel content, very little soil, barren soil, poor water holding capacity, strong water permeability, weak resistance to softening, and poor shear strength, so the tailings form a stable slope. In addition, the terrain of the mining area is strongly cut, the terrain is steep, and the shape of the mountain is steep, so they general...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com