Cooling device applied to laser liquid metal cutting and machining process

A liquid metal and cooling device technology, applied in metal processing equipment, laser welding equipment, manufacturing tools, etc., can solve the problems of inconvenient laser cutting of liquid metal, low melting point of liquid metal, and more incision fluid, etc., to achieve convenient and effective cutting, high power The effect of high density and lower production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

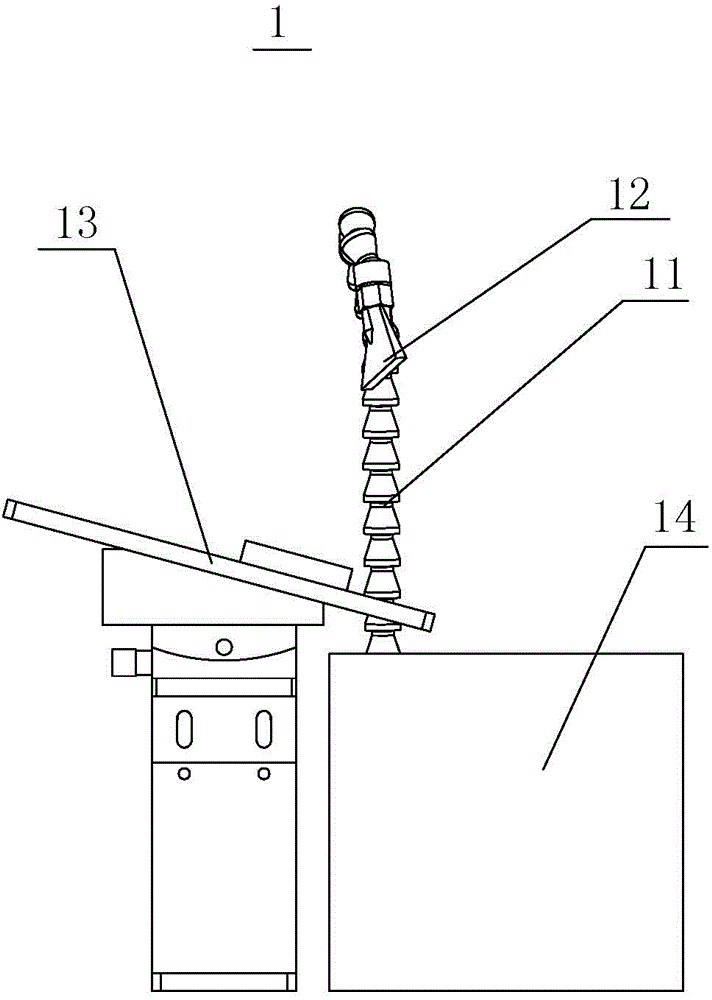

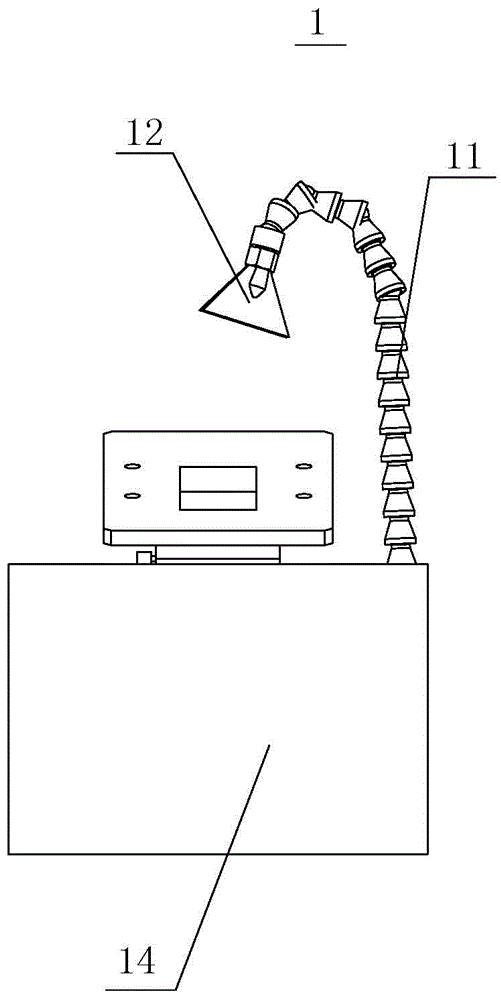

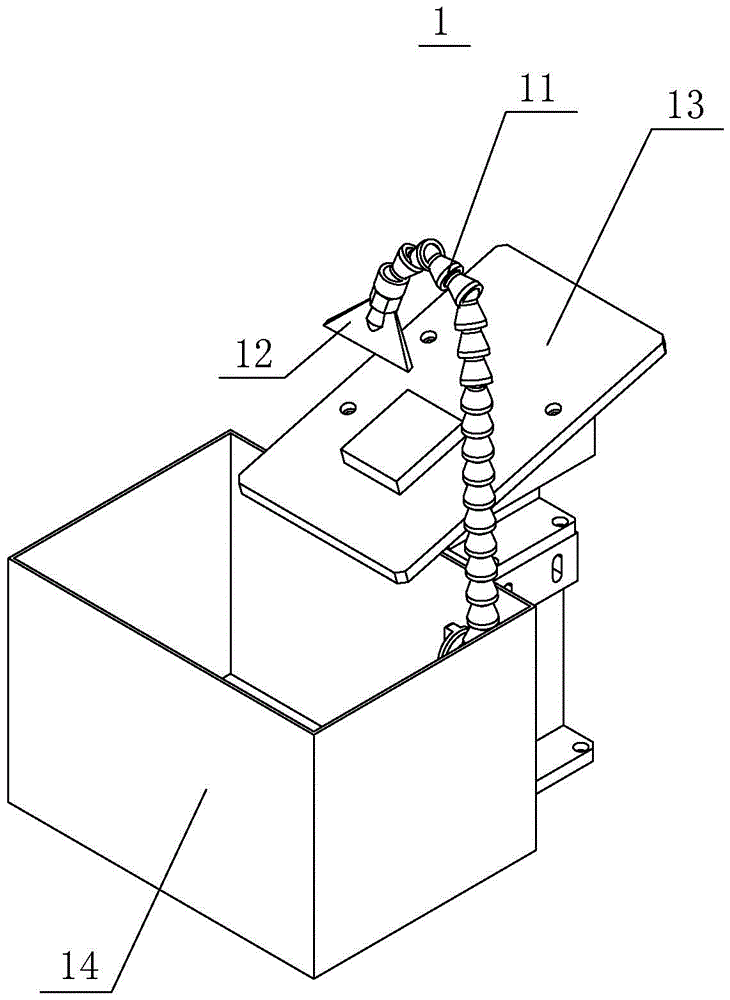

[0036] Such as Figure 1~Figure 3 As shown, the cooling device 1 of the present invention applied to laser cutting liquid metal includes a cooling hose 11, a tuyere 12, a processing table 13 and a water tank 14, and the cooling hose 11 is connected with the tuyere 12. During processing, the The air nozzle 12 is facing the liquid metal processing part on the processing table, so that the water-based paint flowing out from the air nozzle 12 just falls on the kerf of the liquid metal. The water tank 14 is arranged below the processing table 13, so that the water-based paint on the processing table 13 can flow back into the water tank 14; Paint can rise into the cooling hose 11 and flow out of the tuyere 12 . Thus, a water-based paint recycling device is formed, and the water-based paint can be recycled to save resources, reduce pollution, and reduce processing costs.

[0037] The processing table 13 is arranged obliquely, which is beneficial for the water-based paint on the pro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com